스마트 에너지 저장 및 전기차 충전 시스템

An integrated system combining energy storage, solar power, and EV fast charging. Enables intelligent energy scheduling and supports green energy efficiency for electric vehicle infrastructure.

출력 전압: DC 200V - 750V

에너지 용량: 61kWh

치수 크기: 1580 × 965 × 1050 mm

무게: ~840kg

애플리케이션

Combines solar power, buffer storage, and intelligent EV charging to deliver zero-carbon energy solutions.

Dynamically balances charging loads from electric forklifts to reduce peak demand charges.

AI-powered scheduling enables multi-port fast charging while easing grid expansion pressure.

Smart management of second-life batteries extends overall battery lifecycle value.

Off-peak charging aligned with fleet dispatch curves cuts operational costs by up to 30%.

Aggregates distributed energy storage for grid participation and generates additional revenue through energy trading.

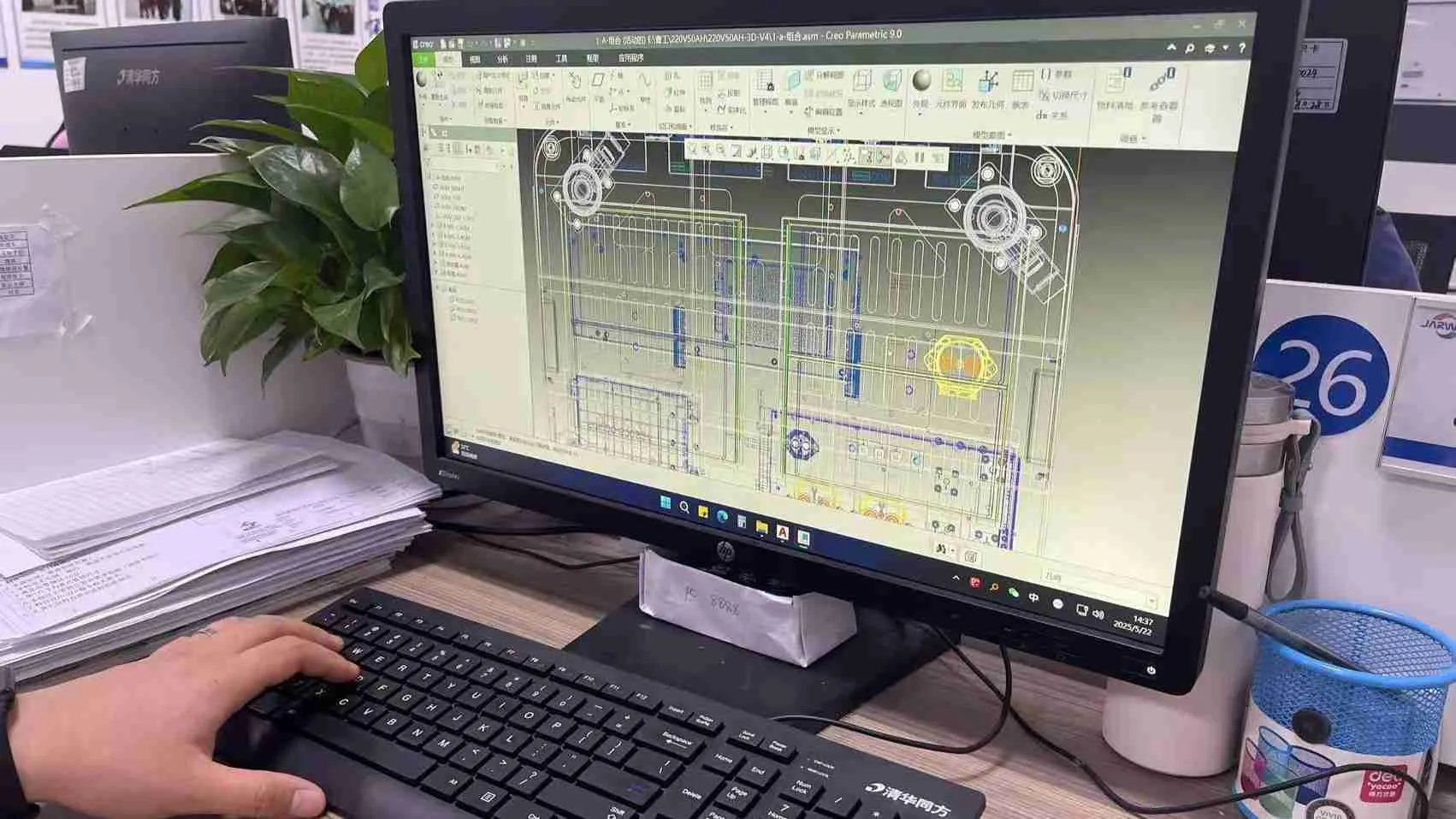

무료 디자인

맞춤형 전용 배터리 플랜! 전문 엔지니어가 일대일로 배터리 프로그램을 계획합니다.

맞춤형 배터리 솔루션으로 드론 효과 극대화

헤레윈 팩토리 살펴보기: 품질의 원천

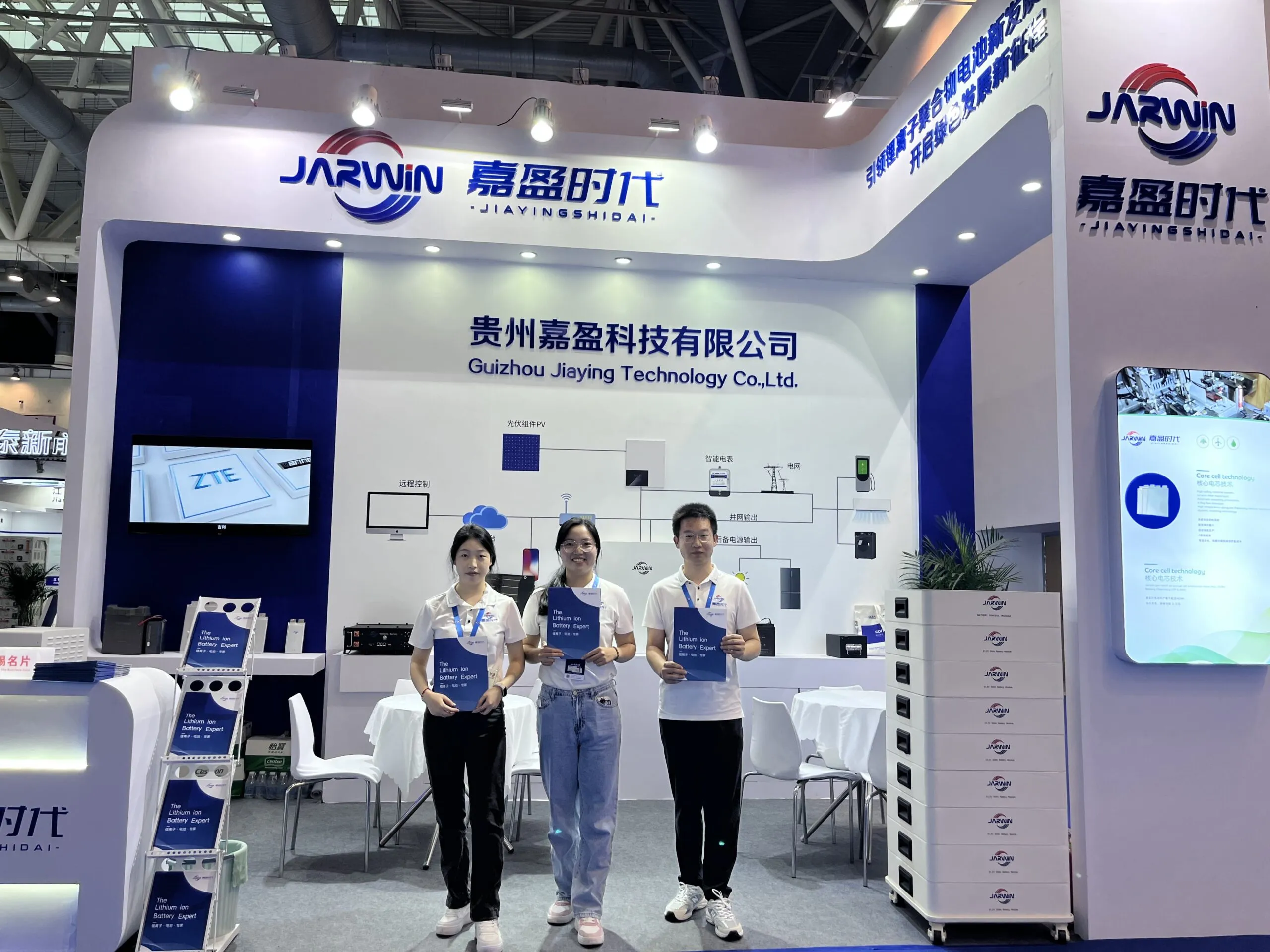

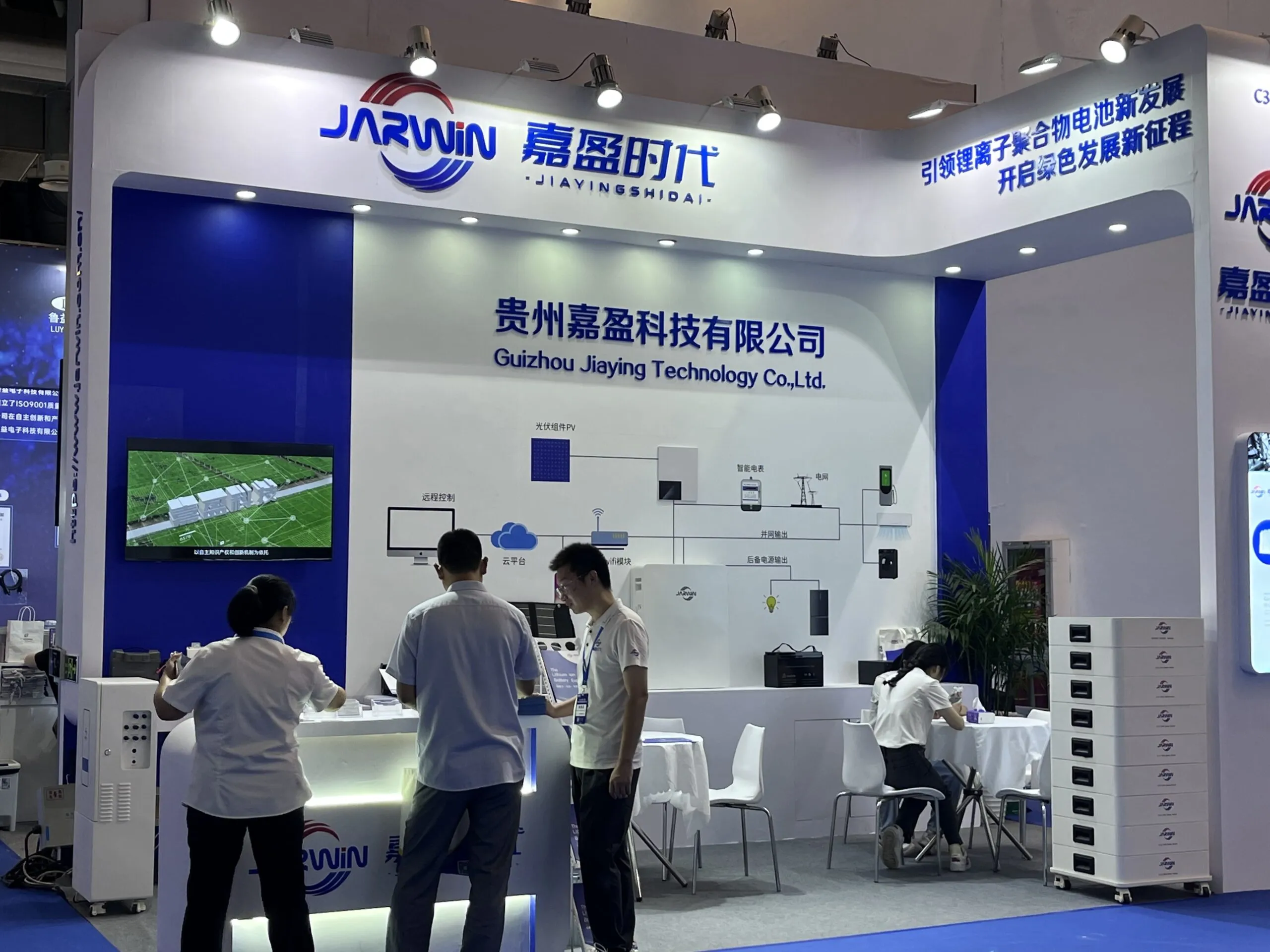

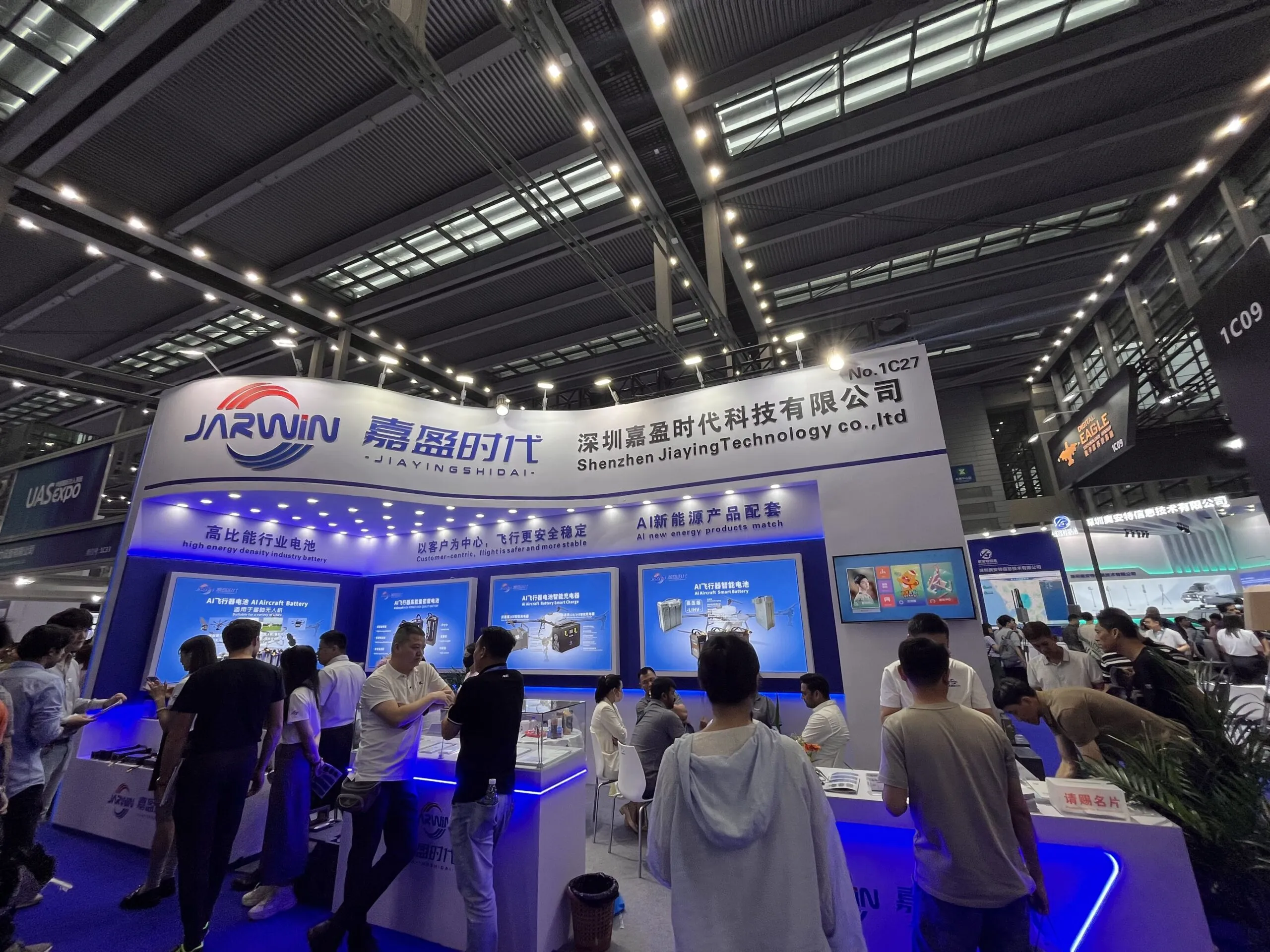

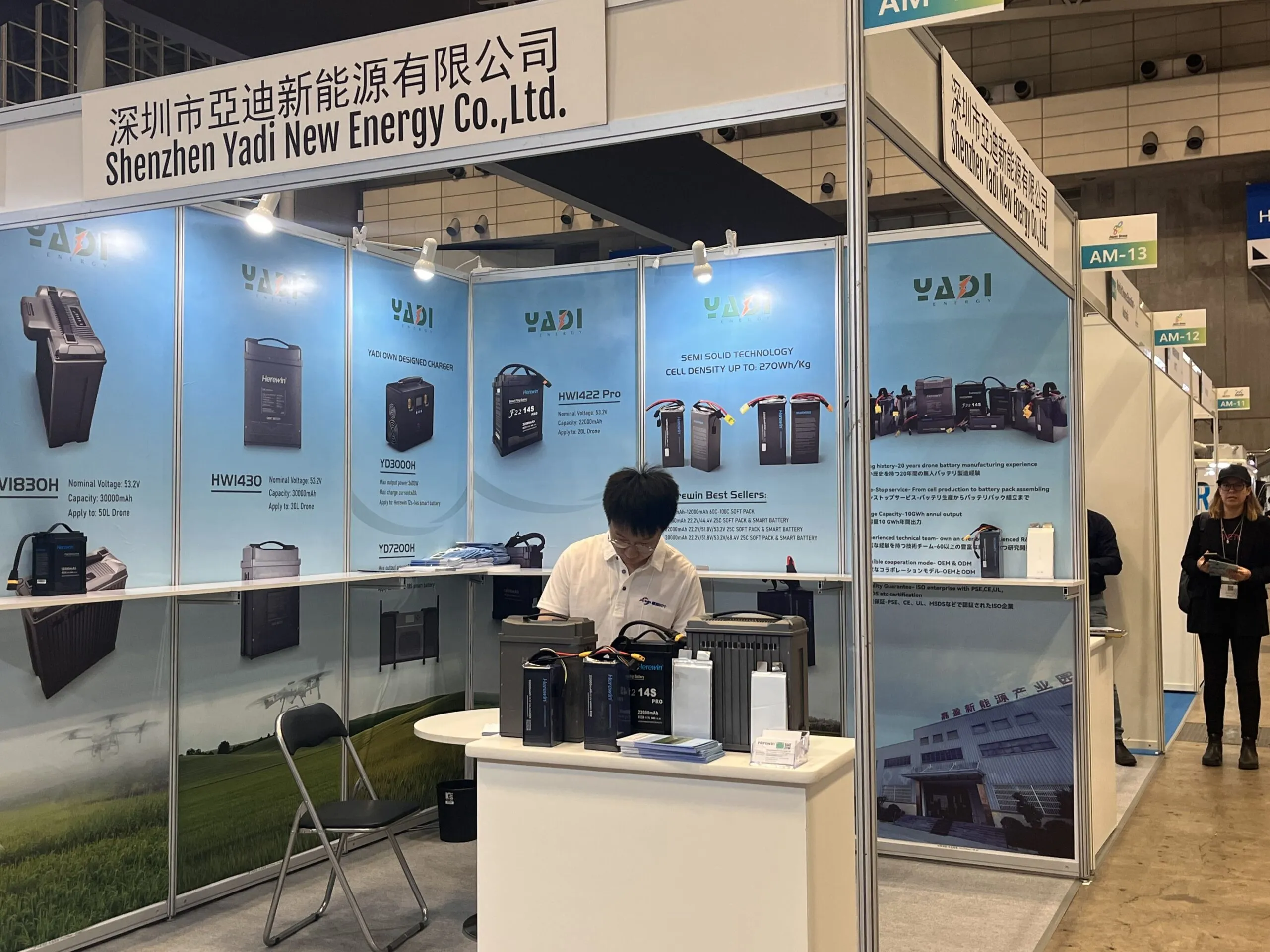

2019년에 설립된 심천 자윈 타임 테크놀로지는 배터리 업계에서 20년 이상의 폭넓은 경험을 가진 설립 및 운영 팀의 지원을 받고 있습니다. 고성능 리튬 이온 폴리머 배터리의 개발 및 생산을 전문으로 합니다.

Facebook이 누구이며 무엇을 지향하는지에 대한 포괄적인 인사이트를 얻으세요. 세심한 정확성을 자랑하는 저희의

생산 라인, 공장의 효율적인 관리, 만족한 고객들의 진정한 피드백이 있었기에 가능했습니다,

프로세스의 모든 단계에서 우수성을 보장하는 방법을 확인할 수 있습니다.

다양한 패턴의 고객을 위한 다양한 서비스

오프라인 고객용

유연한 배송 시간

안정적인 배송 일정 및 창고 지원.

높은 비용 효율성

전체 가치를 극대화하는 경쟁력 있는 가격.

다양한 제품 선택

모든 시장 부문을 충족하는 다양한 옵션.

온라인 고객용

낮은 MOQ

혼합 제품 옵션으로 유연한 MOQ.

사용자 지정 로고

소규모 배치를 위한 맞춤형 로고 사용자 지정.

원스톱 마케팅 패키지

고품질 이미지, 동영상을 제공하여 판매 수익을 높일 수 있습니다.

브랜드 고객용

지역 독점 권한

헤리윈의 모든 리소스 및 기능 제공

R&D Resources

Custom sample within 7 days with R&D capabilities.

빠른 배송

효율적인 생산으로 최단 25일 이내에 배송합니다.

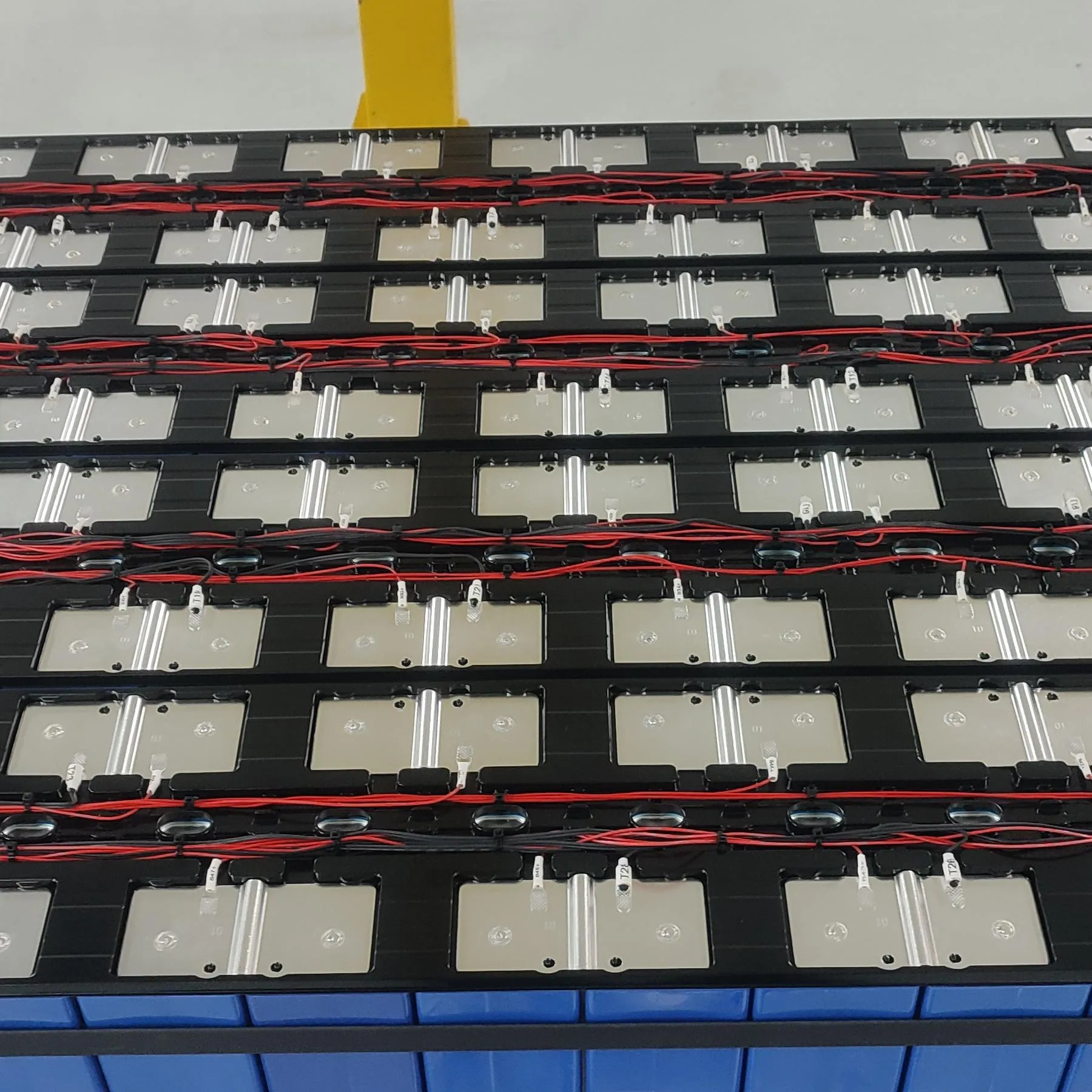

Production Flow of Commercial &Industrial Energy Battery

Verify all incoming cell parameters to ensure they meet quality standards and determine whether the cells are suitable for subsequent production.

Test and classify cells based on open-circuit voltage (OCV) and internal resistance parameters.

Remove dirt, dust, and surface impurities from cells to ensure a clean surface condition for assembly.

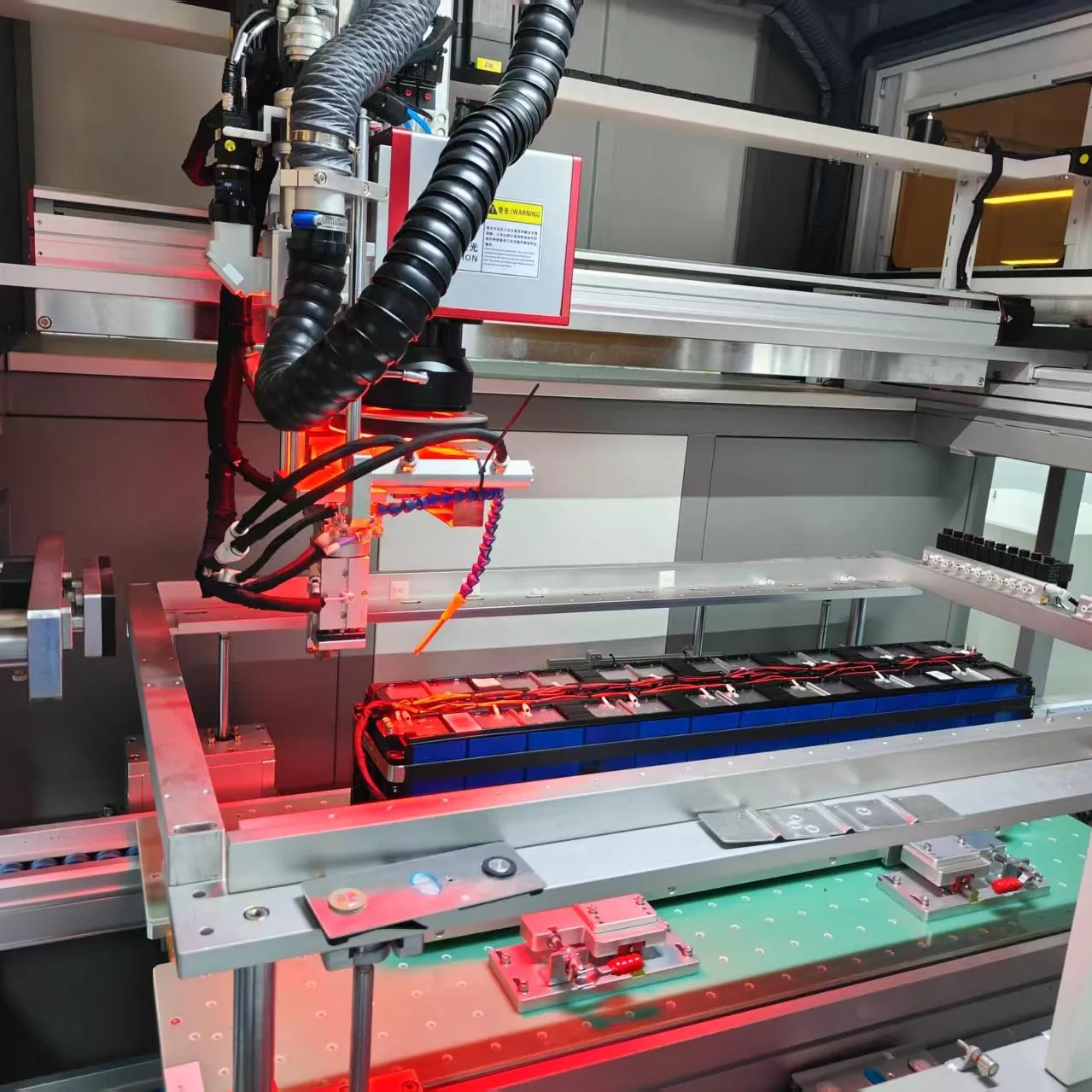

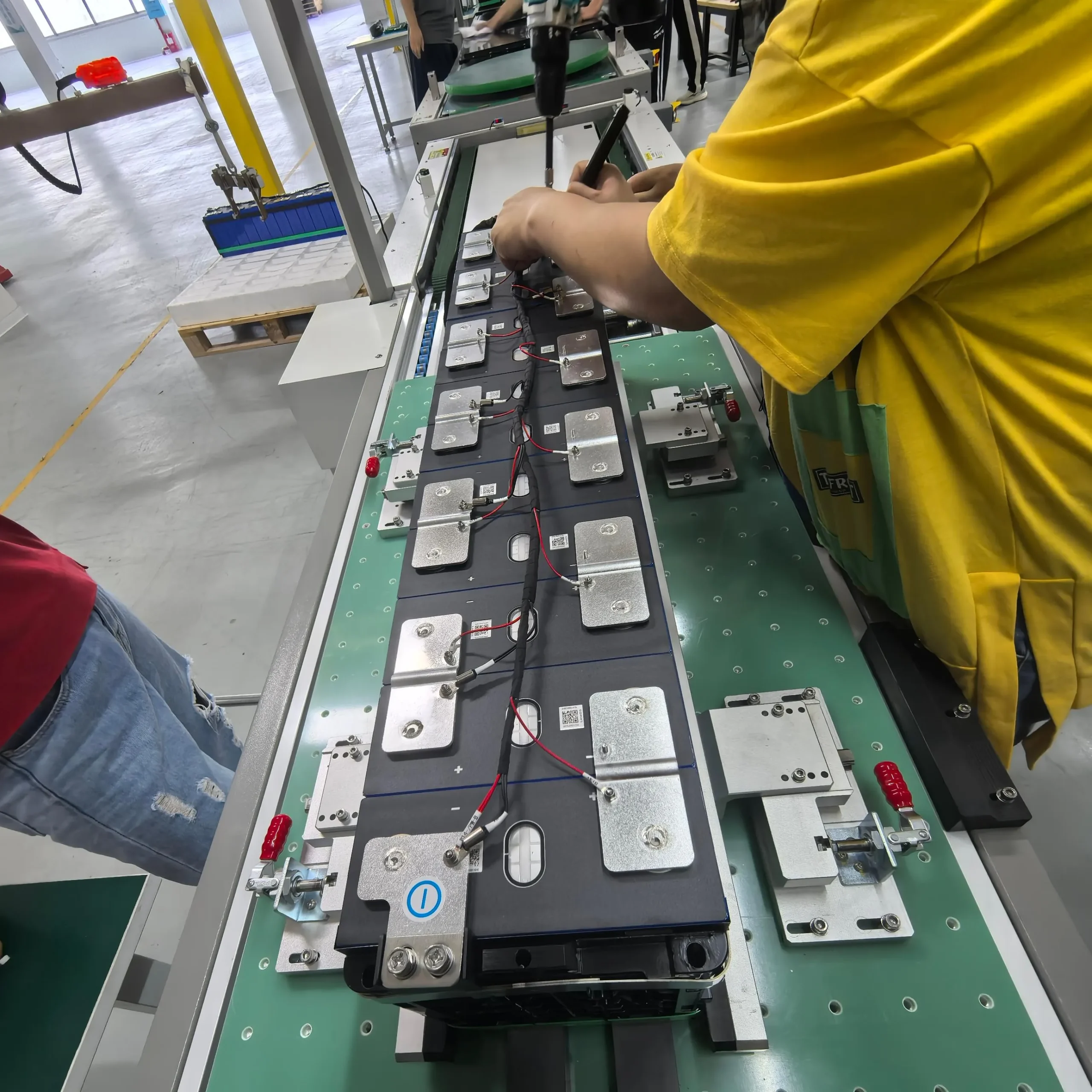

Stack cells in sequence to form modules, apply compression, and install steel bands at the top and bottom of the module.

Install insulated busbar plates onto the module, then perform laser welding and inspect weld quality.

Assemble sampling wire harnesses sequentially, perform laser welding, and conduct visual inspection to ensure welding and assembly quality.

Conduct performance testing on the module to evaluate whether it meets all required technical specifications.

Pre-process components including the connector mounting plate, maintenance cover seal strips, and mounting brackets.

Clean the battery enclosure to remove dust, debris, and other contaminants, keeping both the interior and exterior clean.

Place the module into the enclosure and arrange the wire harnesses neatly to ensure an orderly layout.

Conduct end-of-line testing to verify overall performance and ensure compliance with product standards.

Position and install the top cover securely to complete final assembly.

Perform airtightness testing on the enclosure to verify sealing integrity, followed by final offline product inspection to confirm full compliance with release criteria.

자세히 알아보기

생산 세부 정보 및 제조 공정에 대해 자세히 알아보기

테스트 프로세스

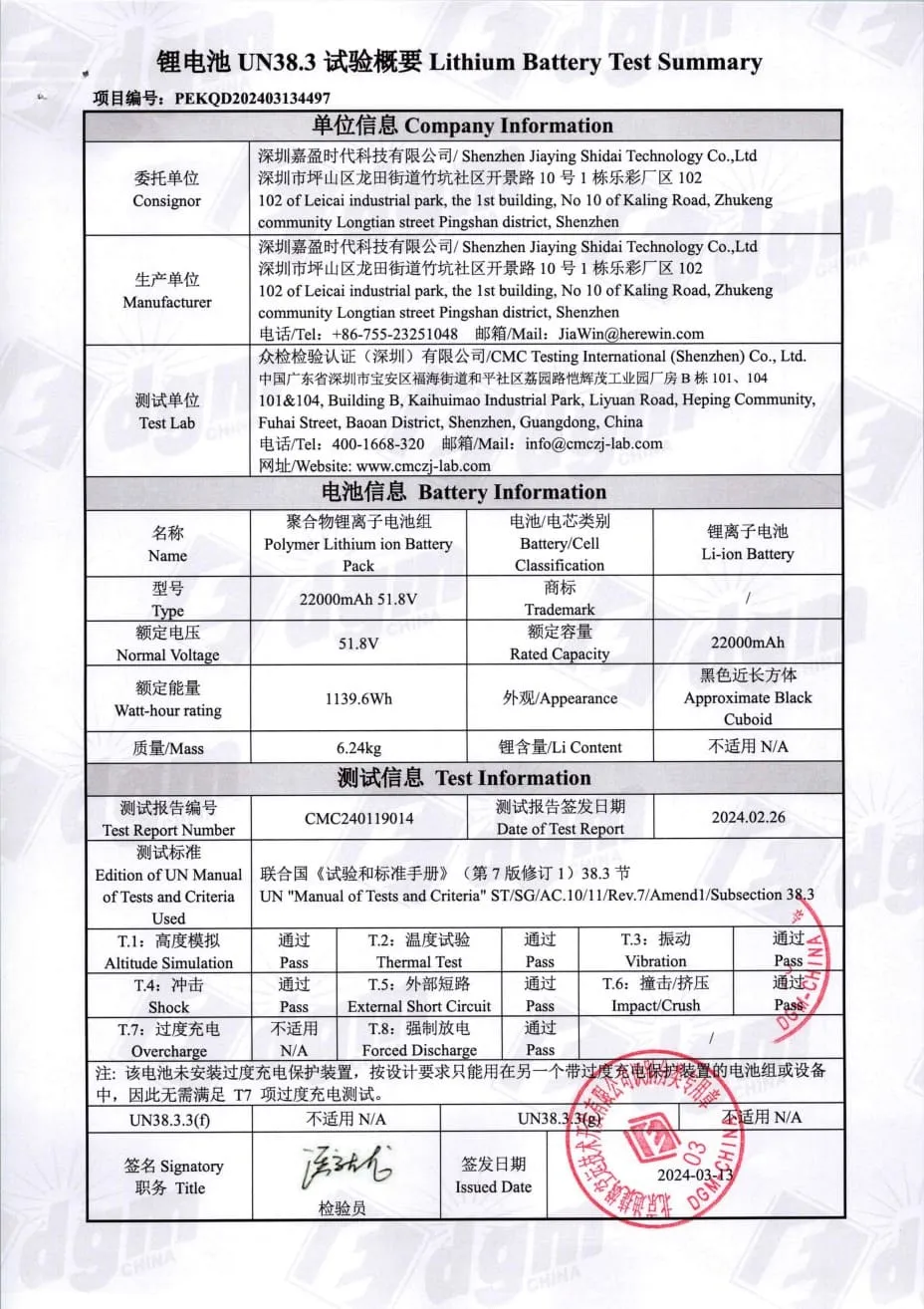

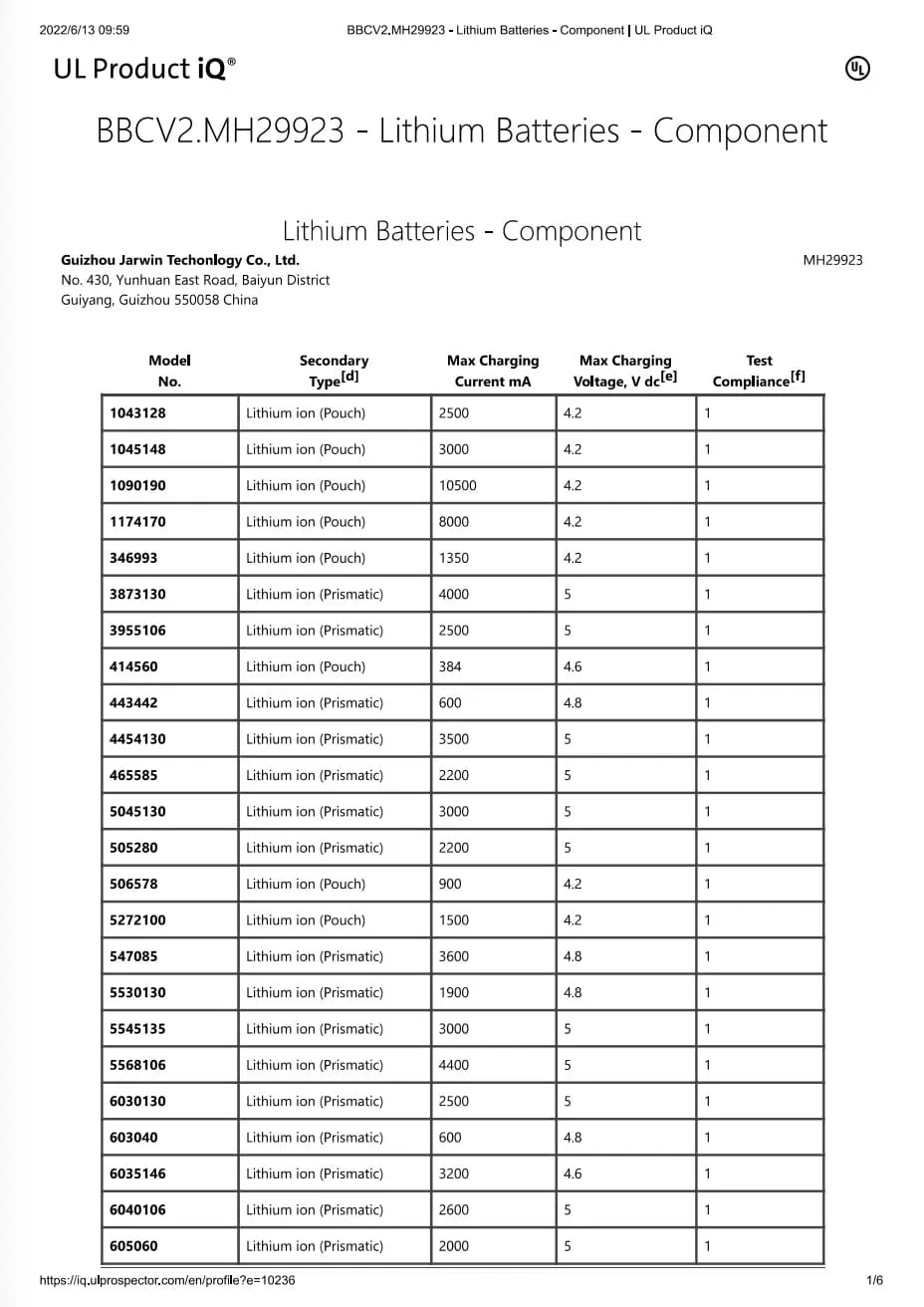

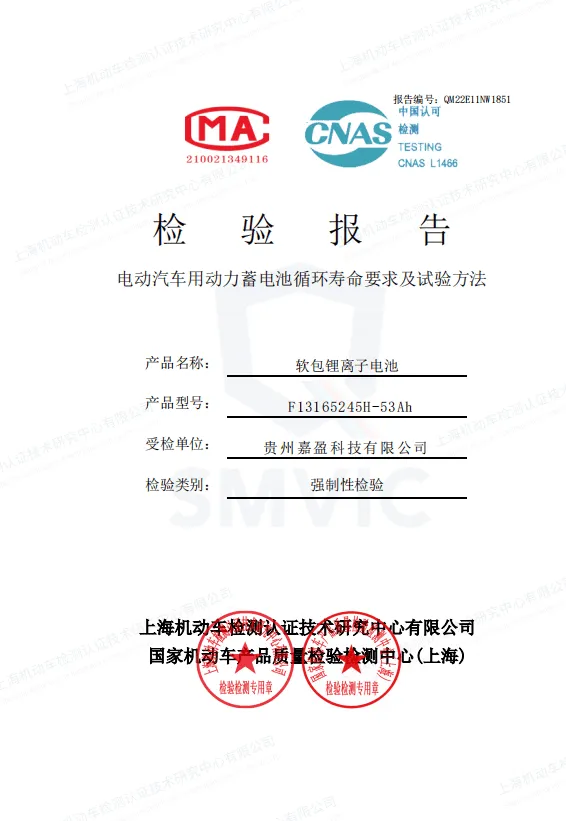

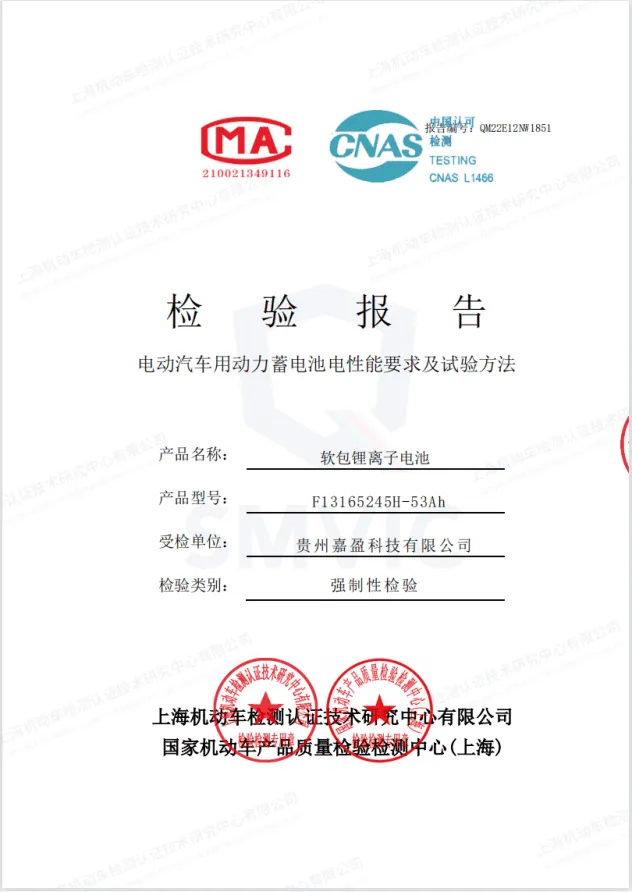

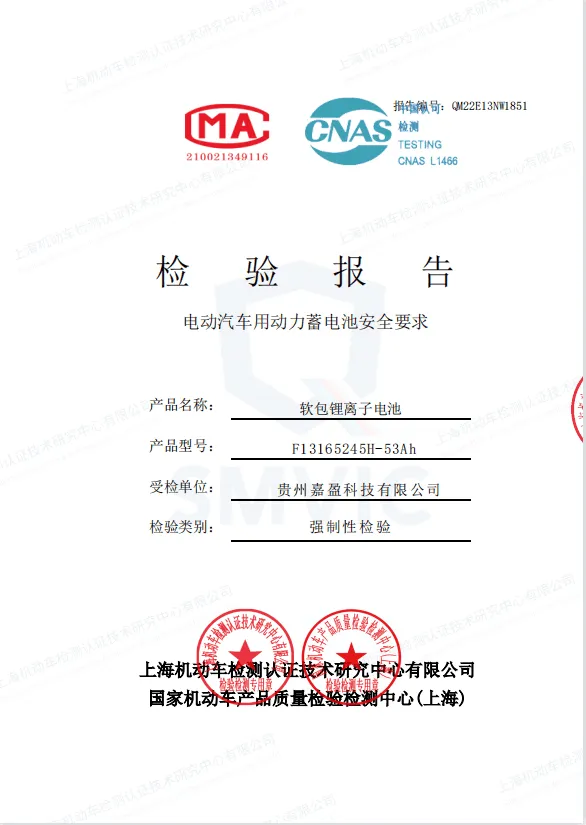

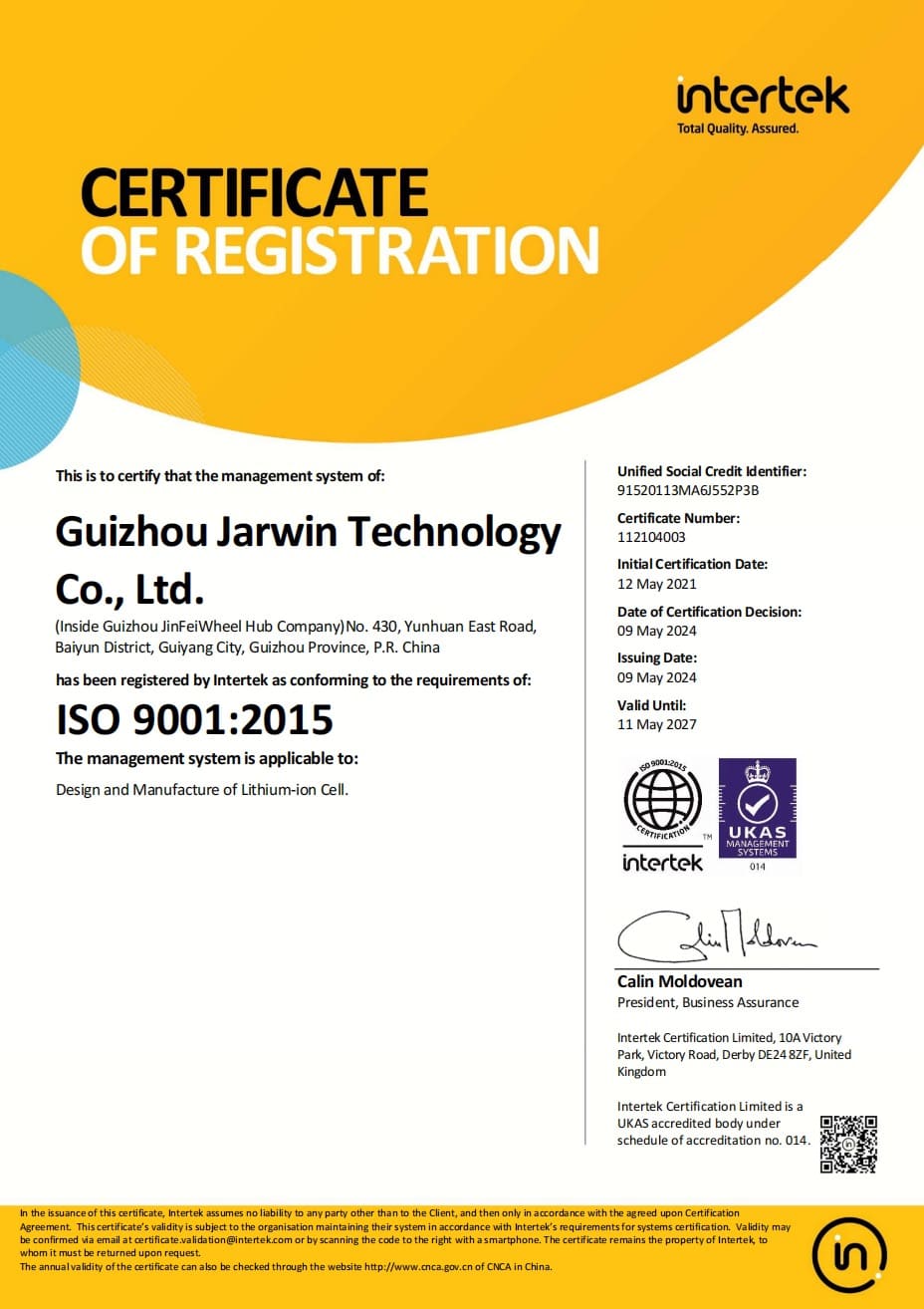

공정 및 인증

인증은 헤리윈의 가장 큰 강점입니다.

모든 시장의 요구 사항을 충족하며, 소스 공장은 품질을 보장하기 위해 완전한 인증을 받았습니다.

연락하기

시장에 필요한 자격 증명이 무엇인지 알고 싶으신가요? 고해상도 이미지를 보내드리려면 연락주세요.

관련 카테고리

자주 묻는 질문

It depends on your electricity consumption and the local peak-valley price gap. In most cases, the system recoups its cost through peak-valley arbitrage and reduced outage losses. For example, in regions like the Pearl River Delta with 10kV dual-rate tariffs, a “two charges, two discharges per day” strategy can achieve full payback within 3 years, followed by 5–9 years of pure electricity cost savings.

관련 블로그

Battery selection is a mission‑critical decision for agricultural drone fleets: the wrong chemistry or inadequate sealing reduces flight duration, limits […]

Industrial mapping teams live and die by endurance, reliability, and data quality. For operators of Platform composite-wing or heavy‑lift multirotors, […]

If you operate a logistics fleet, your battery is more than a component—it affects airtime availability, operational risk, and cross-border […]

Lithium Iron Phosphate (LiFePO4) batteries have become the preferred power source for energy storage, electric vehicles, and portable devices, thanks […]

As the “power core” of drones, lithium batteries directly determine flight stability, endurance, and safety. However, issues like reduced capacity, […]

새로운 카탈로그

Learn more about Commercial &Industrial Energy Storage Solutions, and the full range of products