High temperatures can significantly reduce the lifespan of your forklift battery, sometimes cutting it in half. A high temperature battery is more likely to experience rapid chemical reactions, causing it to lose charge faster and operate less efficiently. When a forklift battery is exposed to elevated temperatures, the risk of thermal runaway increases, and even a slight rise in temperature can greatly decrease the battery’s overall efficiency.

The main reasons for these issues include:

High temperature battery environments accelerate chemical breakdown, leading to faster battery degradation.

Excessive heat lowers the capacity of your forklift battery, resulting in shorter run times.

High temperatures cause water to evaporate from the battery cells, which can damage the battery’s internal structure.

Maintaining the proper temperature is essential for protecting your forklift battery and ensuring smooth warehouse operations.

Key Takeaways

High temperatures make batteries wear out faster. This shortens forklift battery life and lowers run time. Heat makes batteries lose charge more quickly. It can also cause overheating or fires, which are dangerous. Checking battery temperature, voltage, and condition often helps stop sudden problems. Smart chargers, good airflow, and regular care keep batteries cooler and safer. New battery technology and monitoring systems help protect batteries in hot warehouses.

High Temperatures: Battery Science

Chemical Reactions and Degradation

Hot weather makes chemical reactions in forklift batteries go faster. Scientists have found that heat speeds up these reactions, which follows the Arrhenius principle. This makes batteries get old more quickly. In lithium-ion batteries, heat breaks down the electrolyte and damages the SEI layer. These problems make the battery less safe and shorten its life. Lead-acid batteries also get worn out faster in heat. When it is hot, the inside parts break down more quickly. If the temperature goes up by 10°C, a lead-acid battery can last only half as long. Batteries kept in hot places do not last as long as cool ones.

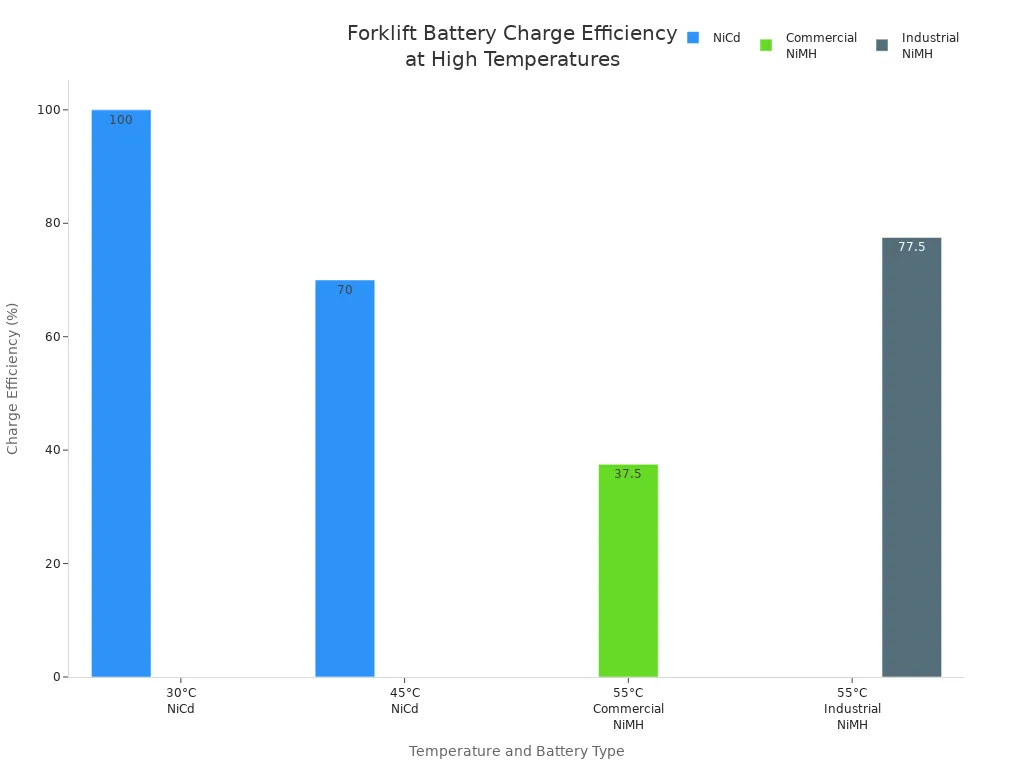

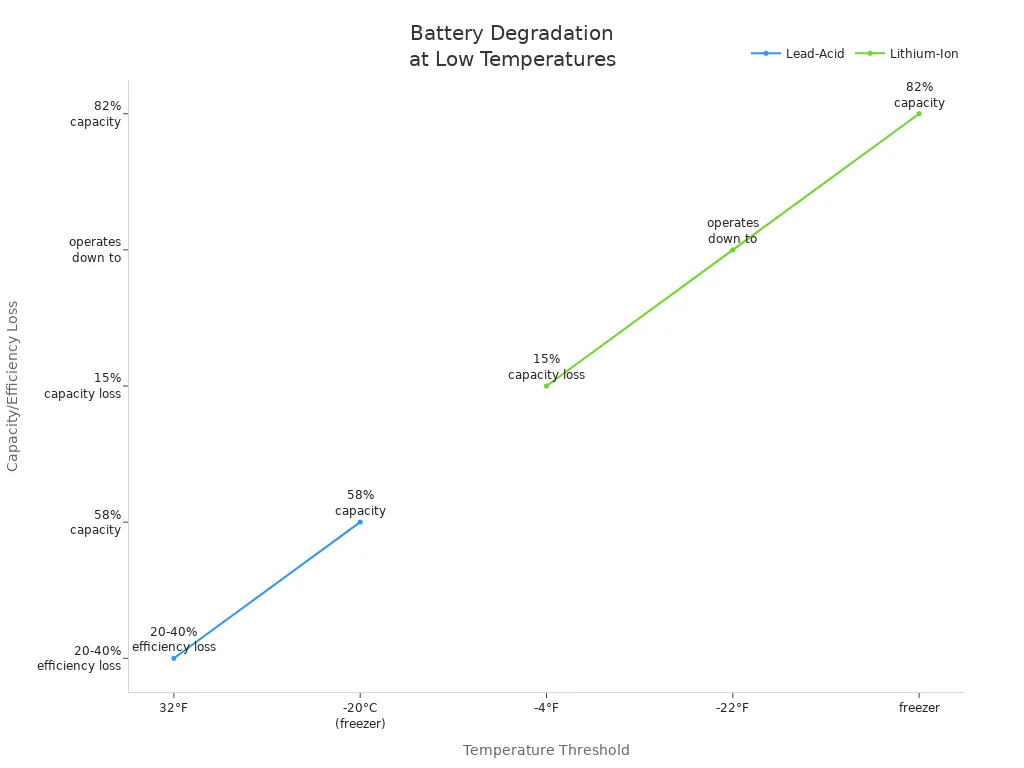

Optimal Operating Temperature Range | Capacity/Efficiency Loss at Low Temperatures | Heat Tolerance and Effects on Degradation | |

|---|---|---|---|

Lead-Acid | 50°F to 95°F | 20-40% efficiency loss at 32°F; 58% capacity at -20°C | Needs cooling above 95°F due to fast degradation |

Lithium-Ion | 68°F to 77°F (optimal); stable up to 130-140°F with BMS | 15% capacity loss at -4°F; 82% capacity in freezer; some models work at -22°F | Heat is main cause of degradation; stable up to 140°F with BMS |

Self-Discharge and Capacity Loss

Batteries lose their charge faster when it is hot. If a forklift battery sits in heat, it will lose power even if not used. In lithium-ion batteries, heat changes the SEI film and causes other reactions. These changes make it harder for the battery to hold a charge. Lead-acid batteries lose water when they get hot, which can cause sulfation and rust. Both types of batteries need to be charged more often after being in heat. This extra charging wears them out faster. You might see your forklift battery runs out of power sooner after being in a hot warehouse.

Thermal Runaway Risks

Thermal runaway is a big danger for forklift batteries in heat. If a battery gets too hot, it starts reactions that make even more heat. This can cause the battery to catch fire or even explode. Lithium-ion batteries are at higher risk. If the separator melts or the battery is overcharged, thermal runaway can start. The risk is worse if batteries are packed close together or if one cell gets too hot and spreads heat. Lead-acid batteries can also have runaway, but lithium-ion batteries in forklifts are more likely to have this problem in hot places. You should watch for signs of overheating and use cooling to keep batteries safe.

Forklift Battery Performance Issues

Reduced Capacity and Run Time

Hot weather makes forklift batteries not last as long. The battery loses power faster, so you must charge it more. Heat makes the battery’s chemicals react quicker. The battery’s active parts break down and cannot hold energy well. This means the battery does not last as long during work shifts.

Note: If your warehouse is hotter than 92°F (33°C), your forklift battery might only last half as long as normal. You will have to get a new battery sooner than you thought.

The battery may not store as much energy as before. Even after charging, the forklift might not work for a full shift. Charging quickly in hot weather makes things worse. The battery gets even hotter and takes more damage. This lowers how well it works. You will spend more time charging and less time using the forklift. This can slow down your work.

Failure and Downtime Risks

Heat can make forklift batteries stop working suddenly. If the inside gets too hot, parts can break or fail. You might notice the voltage drops, strange smells, or the battery feels hot. If you do not pay attention, the battery could stop working without warning.

Here are some important things to check to spot problems early:

Voltage levels: Make sure the battery has the right voltage.

State of Charge (SOC): Watch how much charge is left.

Thermographic imaging: Use this to find hot spots early.

If you do not check these things, you might have surprise downtime. Overheated batteries can stop your forklift in the middle of a job. This wastes time and can make you miss deadlines. Sometimes, one bad battery can stop the whole warehouse.

Safety Hazards

Forklift safety is a big problem when batteries get too hot. High temperature battery problems can be very dangerous. Some common risks are:

Electrical short circuits from broken wires or bad connectors. These can start fires or cause sparks.

Gas can build up while charging. This gas can explode if it is not let out safely.

Chargers in stuffy rooms can make batteries even hotter. This can cause thermal runaway, explosions, or bad fumes.

⚠️ Always follow safety rules. Make sure your charging area has good airflow and never ignore warning signs from your battery.

There are chemical dangers too. Acid inside some batteries can burn your skin or eyes if it leaks. Electrical dangers, like shocks or shorts, get worse when the battery is hot. Fire risks go up in very hot weather, especially if hydrogen gas escapes while charging.

You can make things safer by using smart chargers, checking batteries often, and keeping good records. Many companies have fewer safety problems after doing these things. For example, one warehouse had no battery downtime and 70% fewer safety problems after making these changes.

If you know about these heat dangers, you can keep your team, your forklifts, and your work safe.

herewinpower Solutions for High Temperature Battery Challenges

Industrial EV Battery Packs: Advanced Protection

Forklift batteries must work well, even when it is hot. herewinpower’s industrial EV battery packs help with this. These packs have strong cases that block dust, water, and heat. The battery management system checks the temperature all the time. It stops the battery from getting too hot. You can count on these batteries to work in tough warehouses.

The battery management system protects against high temperatures.

The strong case keeps the battery safe from rough places.

The battery keeps its power and works well in hot weather.

Battery Cell Technology and Safety

herewinpower uses special battery cell technology to keep you safe. This technology also helps your equipment run well. The semi-solid-state design mixes solid and liquid parts. This helps stop the battery from getting too hot or swelling. The lithium iron phosphate chemistry lets the battery work safely in very hot places. Special gel polymer separators and ceramic coatings make the battery even safer in heat.Every batch of batteries is tested for safety. Tests include drop and fire tests to make sure it is safe for you.

Feature/Aspect | Supporting Detail |

|---|---|

Cycle Life | Over 3500 cycles at 70% Depth of Discharge (DOD) |

Temperature Performance | Reliable operation in extreme heat |

Safety Features | Gel polymer electrolytes and ceramic coatings reduce fire risk |

Battery Management System | Real-time monitoring and predictive maintenance |

Certifications | UN38.3, MSDS, CE, RoHS |

Smart BMS and Remote Monitoring

You can trust herewinpower’s smart battery management system to keep batteries safe. The system uses sensors to watch the temperature. It warns you if the battery gets too hot. It balances the battery cells and controls charging to stop overheating. You can check battery health from anywhere using remote monitoring. The system sends alerts for maintenance. This helps you fix problems before they stop your forklifts. Your forklifts keep running and your team stays safe.

The battery management system tracks temperature, voltage, and charge.

Remote monitoring lets you check battery health and get alerts anywhere.

The system helps you plan maintenance and avoid sudden breakdowns.

herewinpower cares about safety, new ideas, and long battery life. This means you get batteries that work well, even in very hot places.

Prevention and Best Practices

Maintenance and Charging Tips

You can make batteries last longer by taking care of them. Check and clean the battery often. Wipe the terminals to stop rust and help power flow. For lead-acid batteries, add water when needed so the inside parts do not wear out. Always use the right charger for your battery’s type and size. Smart chargers change how they charge based on the battery’s needs. This helps stop overcharging.

Make sure the charging area has good airflow. Open the battery cover while charging to help it cool down. If you see leaks or the battery gets hot, stop charging. Let it cool before you start again at a lower speed. Follow the charging rules from the maker. Do not let the battery lose more than 80% of its charge. Try not to stop charging in the middle. These steps keep the battery at a good temperature and stop damage.

Tip: Charge batteries after an eight-hour shift or if they lose more than 30%. Do not leave empty batteries sitting for a long time.

Environmental Controls

Warehouses need to control the air and temperature to keep batteries safe. Keep the temperature between 68°F and 77°F. Use fans and cooling systems to move air and stop hot spots. Control humidity to stop rust, which is very important for lithium-ion batteries. Store batteries in cool, dry places where the temperature does not change much. Use fire-safe boxes and fire systems for extra safety.

Some warehouses are built underground or have thick walls to keep heat out. High ceilings help heat rise away from batteries. Check the warehouse and batteries often to find problems early. Use Warehouse Management Systems to watch battery health and help work go smoothly.

Operational Adjustments

You can change how you work to keep batteries cooler. Charge batteries when it is not too hot outside. Change work shifts so batteries do not get too hot for too long. Always charge in places with good airflow and use chargers that turn off by themselves. Teach your team the best ways to care for and use batteries.

Set up special charging spots with good airflow, fire safety tools, and clear rules. Do not overcharge and let batteries finish charging each time. These changes, along with regular checks and cooling, help keep batteries at the right temperature and make them last longer.

Hot weather can make forklift batteries stop working sooner. Batteries also do not work as well when it is hot. You can stop these problems by using smart ways to control temperature. Using new solutions like herewinpower helps too. Many companies are safer and spend less money after switching to batteries that handle heat.

Cold storage and outdoor places have fewer battery problems and batteries last longer.

Fast charging and smart checks help stop delays and keep work going.

Experts say you should look at how you use your batteries. Make sure there is good airflow and stay away from very hot or cold places. Think about getting batteries made for tough places to keep your team and equipment safe.

FAQ

What temperature is too hot for a forklift battery?

You should keep most forklift batteries below 95°F (35°C). If the battery gets hotter, it can lose power faster and wear out sooner. Always check the battery temperature during use.

How can I tell if my forklift battery is overheating?

Look for these signs:

The battery feels hot to the touch

You smell something strange

The forklift loses power quickly If you notice any of these, stop using the battery and let it cool.

Can I use a fan to cool my forklift battery?

Yes, you can use a fan. A fan helps move air around the battery and keeps it cooler. Make sure the fan blows air across the battery, not just in the room.

How often should I check my forklift battery in hot weather?

Task | How Often |

|---|---|

Check temperature | Every shift |

Inspect for leaks | Daily |

Clean terminals | Weekly |

You should check your battery more often when it is hot. This helps you catch problems early.

See Also

Advanced Battery Technologies Enhancing Forklift Performance Across Africa

The Rise Of Swappable Batteries Driving Electric Motorcycle Innovation

Innovative Battery Replacements And Custom Lithium Services For Indian Vehicles

Herewin’s Tailored Battery Designs Boost Heavy-Lift Drone Performance

Why Timely Drone Battery Replacement Is Vital For Peak Performance