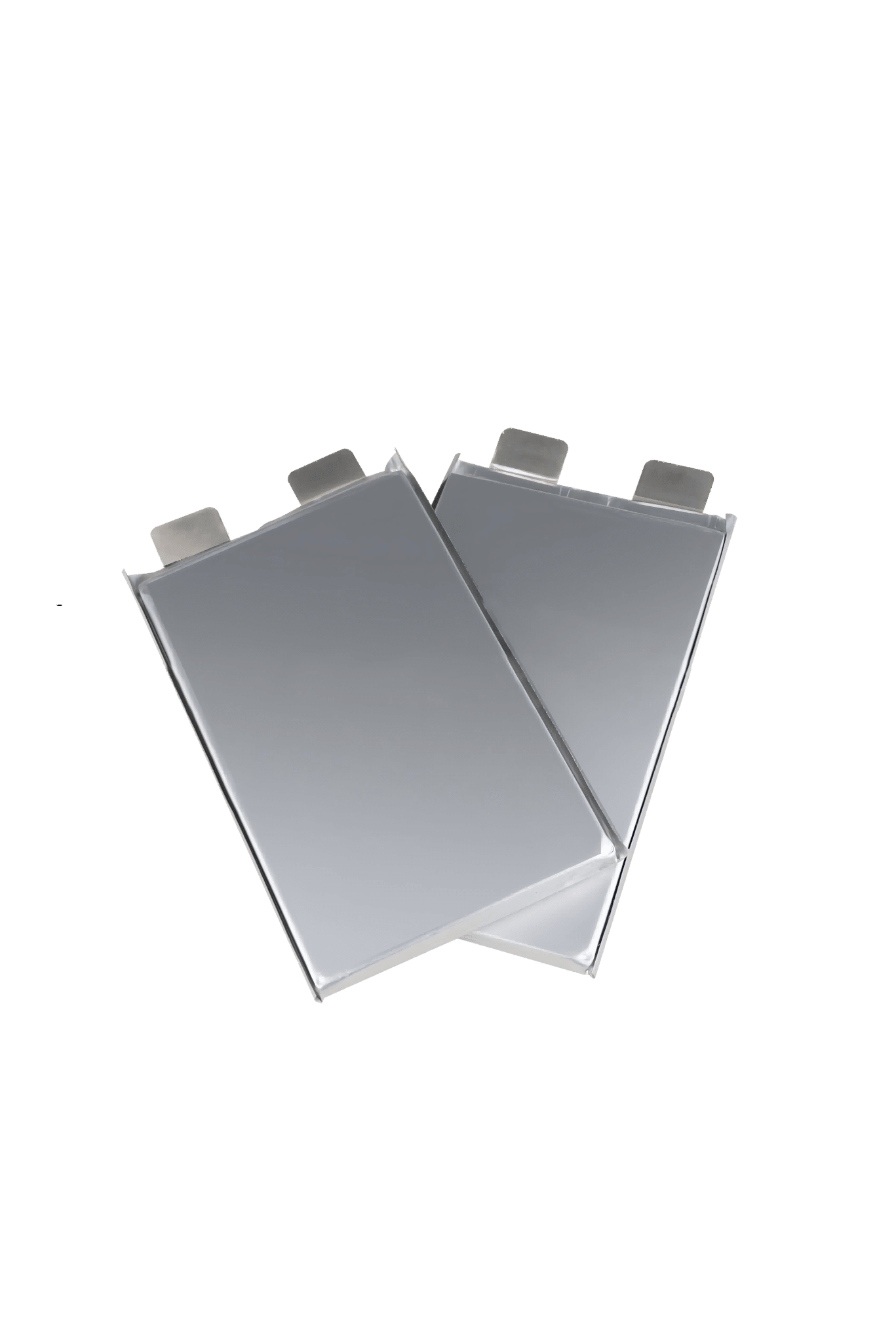

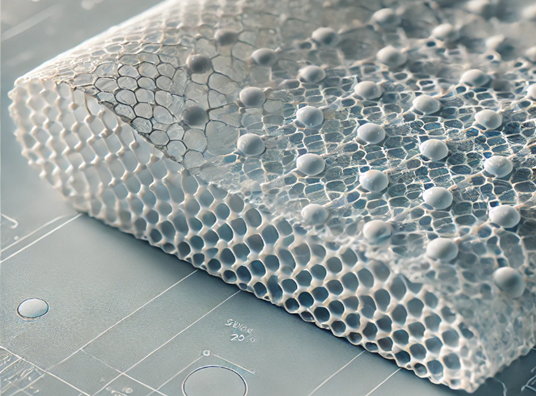

In the microscopic world of lithium-ion batteries, there lies a seemingly fragile yet critically important component—the battery separator, just 10 to 25 micrometers thick. Despite its ultrathin structure, this film plays a vital role in both the safety and performance of the battery.

Acting as a “dual-sided guardian,” the separator performs two essential tasks: physically insulating the anode and cathode to prevent short circuits, and simultaneously enabling lithium-ion transport through a network of nano-scale pores—typically around 0.01 to 0.1 micrometers in size. Even subtle differences in pore size and porosity can significantly impact the battery’s charge and discharge efficiency.

Today, let’s uncover the hidden science behind this micron-scale material and explore how it shapes the future of lithium battery technology.

Why Choosing the Right Battery Separator Requires a “7-Dimensional” Standard

Traditionally, battery separators were selected based mainly on cost and a few basic parameters such as thickness and air permeability. However, with the rise of advanced battery applications—such as electric vehicles and large-scale energy storage systems—the performance demands placed on separators have expanded dramatically. Today, a comprehensive evaluation requires a seven-dimensional approach:

-

Electronic Insulation

The separator must physically isolate the anode and cathode to prevent direct contact, effectively avoiding internal short circuits. -

Pore Size and Porosity

Proper pore size and porosity ensure low internal resistance and high ionic conductivity, facilitating efficient lithium-ion transport. -

Chemical Stability

The material must resist degradation in the electrolyte, maintaining structural integrity and avoiding unwanted chemical reactions. -

Electrolyte Wettability

Good wettability and electrolyte retention enhance ion mobility and contribute to overall battery performance. -

Mechanical Strength

The separator should possess adequate mechanical properties—such as puncture and tensile strength—to withstand battery assembly and operational stress. -

Dimensional Stability and Flatness

A stable and flat separator structure helps maintain the internal architecture of the battery, contributing to long-term reliability. -

Thermal Stability and Shutdown Function

High thermal stability allows the separator to maintain performance under elevated temperatures. Some advanced separators also feature a thermal shutdown function that closes the pores when overheating is detected, helping to prevent thermal runaway.

Three Representative Separator Technologies: A Closer Look

Ceramic-Coated Separators (Preferred for EV Applications)

- Structure: Base film (PE/PP) coated with nano-sized Al₂O₃ or boehmite particles (coating thickness approx. 2–5 μm)

- Advantages:

-

-

Exceptional thermal stability with shrinkage <0.5% at 180°C

-

Puncture resistance of 280 N/μm—90% higher than conventional separators

-

Ideal for high energy density lithium-ion batteries in electric vehicles

-

Gel Polymer Separators (Built for Extreme Conditions)

- Technology: Dual cross-linked polymer networks lock in liquid electrolyte

- Performance:

-

-

Maintains ionic conductivity of 2.2 mS/cm at -40°C (compared to 0.5 mS/cm for traditional separators)

-

Microcapsule-based self-healing technology repairs micron-scale cracks within 30 seconds, enhancing safety by up to 3x

-

Suitable for batteries operating in extreme cold or unstable mechanical environments

-

Aramid Composite Separators (Designed for Long-Life Applications)

- Materials: Reinforced with para-aramid fibers (tensile strength up to 3.8 GPa) and biomimetic self-healing coating

- Performance:

-

-

Cycle life exceeds 8,000 cycles (vs. industry average of ~3,000)

-

Reduces annual maintenance costs by up to 60%

-

Ideal for long-duration energy storage systems, 5G base stations, and other high-reliability use cases

-

Herewin’s Process for Selecting High-Quality Battery Separators

At Herewin, selecting high-performance battery separators involves a rigorous, multi-step process designed to ensure that every separator entering our production line meets the highest standards of safety, compatibility, and reliability.

Initial Screening and Evaluation

Herewin begins by collecting samples from potential separator suppliers and conducting a preliminary screening based on key parameters such as thickness, porosity, and air permeability. Products that fail to meet basic requirements are eliminated. At the same time, we evaluate the supplier’s manufacturing qualifications, R&D capabilities, and environmental certifications to ensure a trustworthy and sustainable source.

7-Dimensional Performance Testing

For samples that pass the initial screening, Herewin conducts in-depth testing based on our proprietary “7-Dimensional Evaluation System.”

-

-

Safety Dimension: Includes UL 9540A thermal runaway testing and puncture tests (e.g., 150°C for 30 minutes with no ignition) to eliminate safety risks.

-

Performance Dimension: We measure key indicators such as ionic conductivity (≥3.5 mS/cm) and thermal shrinkage rate (<1% at 180°C).

-

Compatibility Dimension: Porosity is verified for alignment with specific battery chemistries—for example, 40±2% porosity for NMC systems.

-

Laboratory Simulation Testing

Qualified separators are assembled into test cells and subjected to laboratory simulations that replicate real-world usage conditions—extreme temperatures, high-rate charging and discharging, etc. For instance, Herewin conducts 1,000-hour aging tests between -40°C and 200°C to evaluate long-term durability and thermal stability.

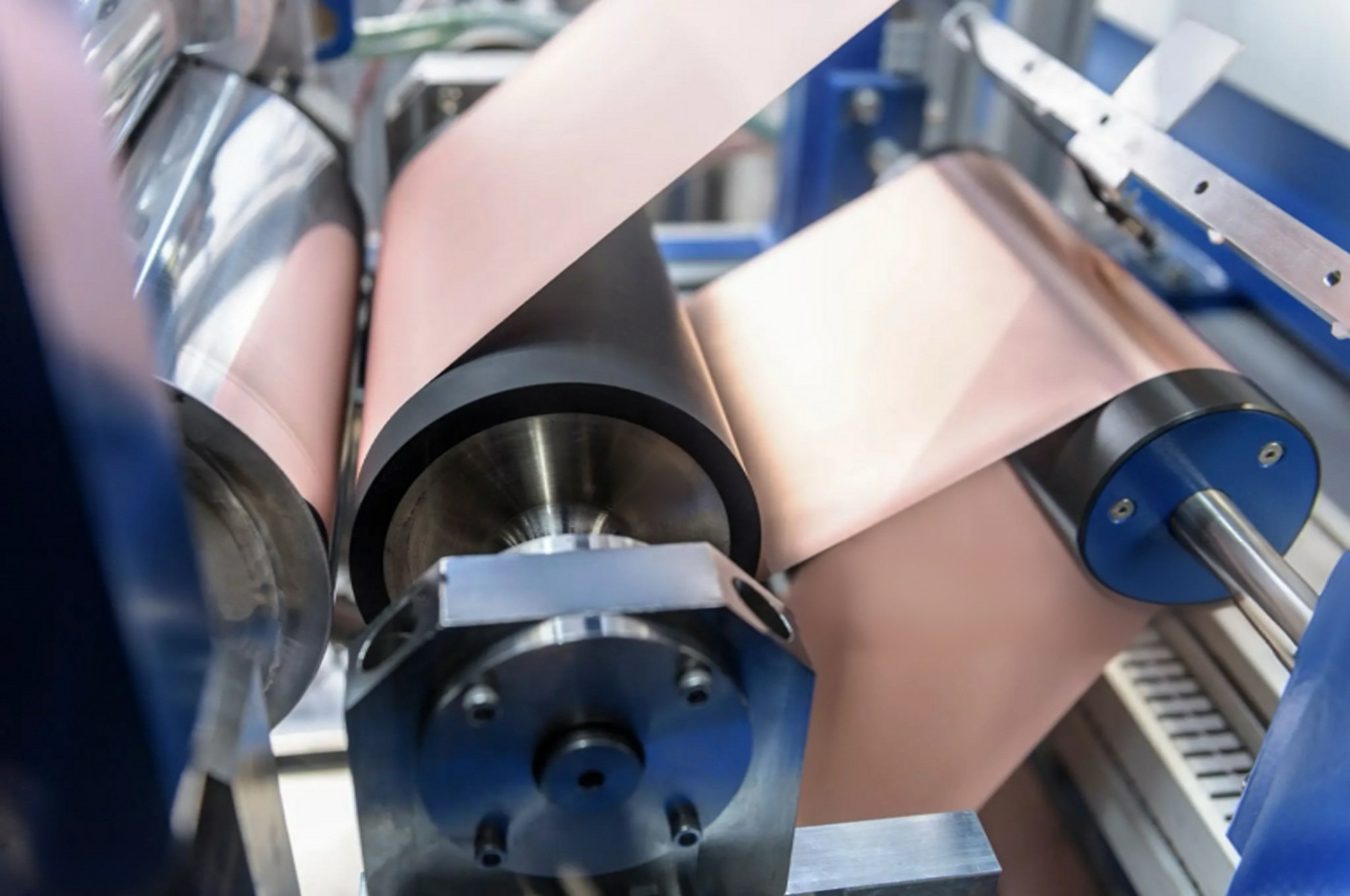

Pilot Line Testing

Separators that pass laboratory validation are scaled up to Herewin’s pilot production line. This step simulates actual manufacturing processes such as coating and winding to test the separator’s processability, as well as its impact on production efficiency and yield.

Application-Specific Field Testing

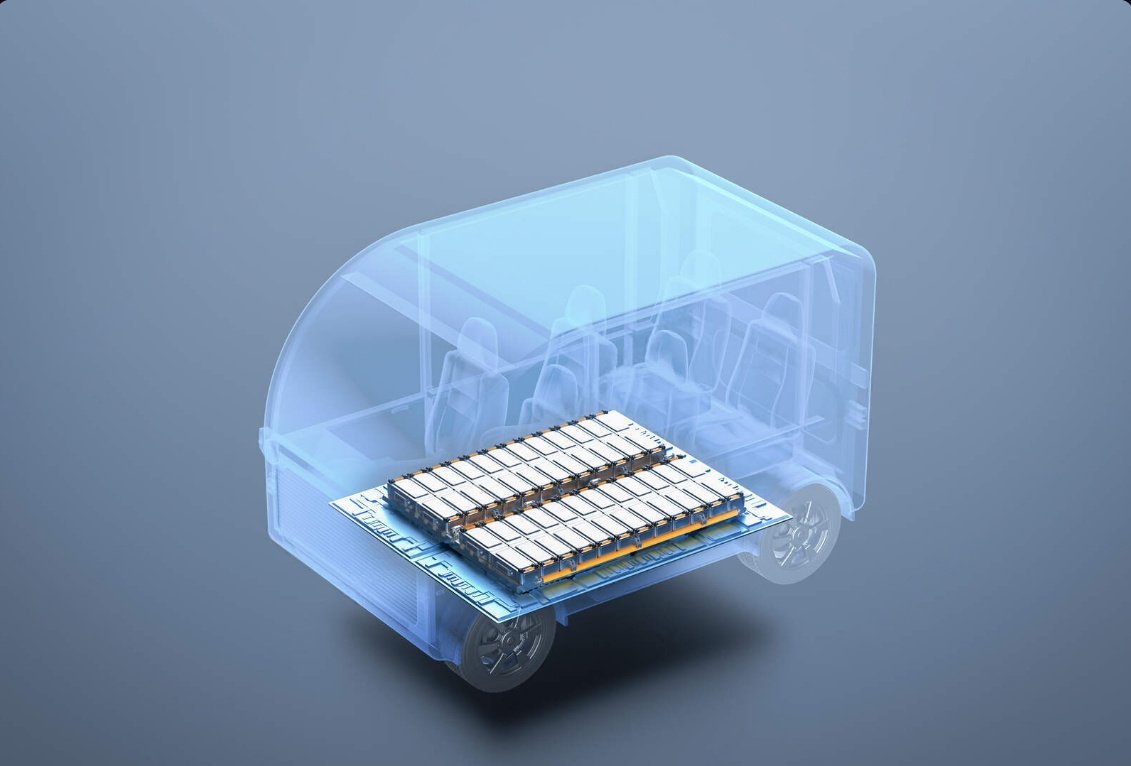

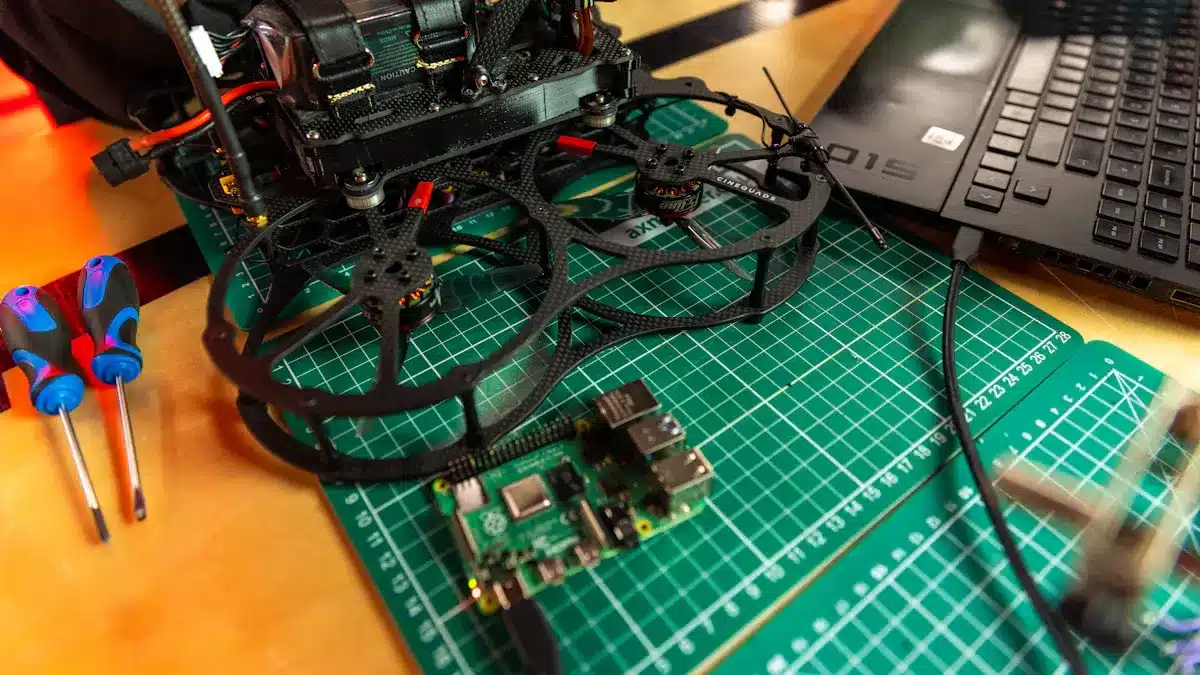

Herewin installs batteries using the candidate separator into real-world devices such as drones, electric vehicles, or energy storage stations, depending on the target market. For EVs, we conduct road tests to evaluate driving range, fast-charging performance, and safety. For energy storage systems, we assess cycle stability under long-term use.

Mass Production Monitoring and Continuous Optimization

Only separators that pass all of the above stages move into mass production. Herewin continues to perform batch sampling inspections and maintains a full-process traceability system, covering everything from raw material batches to production parameters. In addition, we collect market feedback and monitor emerging technologies to continuously refine and upgrade our separator selection standards.

Conclusion

From its microscopic structure to a multi-dimensional selection process, the battery separator—though incredibly thin—is central to both safety and performance. At Herewin, we rely on a proprietary 7-Dimensional Evaluation System to tailor separator solutions for diverse applications, including electric vehicles, energy storage systems, and drones.

Whether it’s surviving extreme cold at -40°C or meeting the demands of over 2,000 charge-discharge cycles, each separator is subjected to microscopic-level inspection and full-process traceability—ensuring it delivers optimal performance for its intended scenario.

Looking ahead, Herewin will continue to invest in innovations in solid-state technologies, intelligent materials, and low-carbon manufacturing. Our mission remains the same: to push the boundaries of battery technology and deliver safer, more efficient, and more sustainable energy solutions for every application.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is a battery separator and why is it important?

A battery separator is a thin microporous membrane placed between the positive and negative electrodes of a lithium-ion battery. It prevents physical contact (avoiding short circuits) while allowing lithium ions to pass through. It plays a critical role in ensuring battery safety, performance, and cycle life.

What materials are used to make battery separators?

Common materials include polyethylene (PE), polypropylene (PP), ceramic-coated films, and aramid fibers. Advanced separators may also use gel polymer or solid-state electrolyte support structures for enhanced safety and thermal stability.

What is the difference between a ceramic-coated separator and a regular separator?

A ceramic-coated separator has a thin ceramic layer (e.g., Al₂O₃) on top of a PE/PP base film. It improves thermal stability, puncture resistance, and safety under high temperature, making it ideal for applications like electric vehicles (EVs) и high-energy-density batteries.

How is a battery separator tested for quality and performance?

High-quality separators are tested for:

-

Ionic conductivity

-

Thermal shrinkage at 180°C

-

Pore size and porosity distribution

-

Electrolyte wettability

-

Puncture strength and tensile strength

-

Compatibility with different battery chemistries

Herewin, for example, uses a 7-dimensional evaluation system and full traceability process to ensure every separator meets demanding standards.

Which battery applications require specialized separators?

Different use cases demand different separator features:

-

EV batteries require high thermal stability and safety.

-

Energy storage systems (ESS) need long cycle life and mechanical durability.

-

Drones and power tools prioritize high-rate performance and lightweight.

Herewin customizes separator solutions for each scenario.