Industrial fleets rarely fail suddenly—they degrade in stages: isolated mid‑flight derates, heat‑related forced landings, then a cluster of “ERR” codes from packs that once performed reliably. This guide is written for fleet and operations technical leads responsible for uptime, sortie cadence, and cost‑per‑flight‑hour. In 2026 that remit increasingly includes battery asset‑lifecycle management (ALM): tracking per‑pack SOH, scheduling rotation and retirement to preserve residual value, and linking BMS telemetry to procurement and warranty decisions.

We ground recommendations in auditable practices and cite authoritative sources for concepts. Where public evidence is limited—such as sustained ≥5C behavior for semi‑solid chemistries—we provide verification methods and operating policies rather than speculative performance claims. When first‑party, auditable test data are approved for publication, we label them explicitly as vendor datasets and attach method details to ALM records.

Industrial drone BMS working principles: what must be measured and why it matters

At its core, the battery management system is the drone’s electrical nerve center. It samples per‑cell voltage, pack and branch current, and a distributed temperature map across cells and heat paths. From these primitives it estimates SOC/SOH, computes internal resistance (ACIR/DCIR), and enforces protections that keep missions predictable.

- Voltage: Industrial fleets need millivolt‑level resolution to detect imbalance trends. Design targets for industrial BMS front ends should aim for sampling precision on the order of ≤0.5 mV per cell so single‑cell deltas can be managed before a weak cell caps usable capacity.

- Current: Capture fast transients to support coulomb counting and to differentiate takeoff bursts from sustained overloads.

- Temperature: Use multiple probes and hottest‑spot tracking; gradient metrics drive derating and thermal budgeting.

Why ACIR/DCIR are your performance lifelines

- DCIR measured by controlled pulse tests is a practical early SOH indicator: rising DCIR correlates with capacity fade in published datasets. Industry analyses often treat ~20% DCIR growth as a warning to investigate accelerated aging; verify the exact link for your cell chemistry and pack form factor before applying retirement rules (ACS impedance analysis, NREL cycle‑life report).

- ACIR at ~1 kHz is a fast ohmic snapshot that helps rapidly flag contact issues (for example, poor welds or tab/ear contacts) before they manifest as DCIR drift. Include a routine 1 kHz ACIR check in your spot‑check SOPs for quick health scans.

Implementation note: Make resistance‑trend logging a first‑class KPI. Correlate DCIR evolution with mission profiles and ambient conditions to expose derate risk windows; include a replication plan in your ALM records (method, sampling window, temperature control).

Protection mechanisms under high load and high C‑rate

Industrial sorties stress packs at takeoff and during heavy‑lift cruise. Your BMS should allow time‑bounded bursts while guarding thermal safety and life.

Dynamic current limits for takeoff

- Use context‑aware overcurrent thresholds: allow short, budgeted windows above nominal current for liftoff, then taper thresholds as hottest‑cell temperature rises or as SoC approaches extremes. Log every allowance and the cumulative thermal budget so fleet managers can tie burst usage to remaining life in ALM records.

Charge‑side derating and segmented charging

- Implement JEITA‑style temperature regions at pack level. At charger and pack‑firmware layers, reduce charge current and adjust regulation behavior outside the optimal band. For operational cadence, adopt a segmented charge policy: 0–80% SOC at 1C fast charge, then switch to 0.5C for 80–100% while forcing active balancing during that slow phase. This pattern reduces time at high SoC under high current and gives active balancers the energy budget to converge cells before return to service.

Discharge‑side thermal derating and ramp‑rate control

- Tie allowable continuous C‑rate to hottest‑cell temperature and SoC, permit brief, time‑budgeted bursts, and enforce interrupt thresholds on rapid ramp rates (°C/min). Thermal management surveys show that improved BTMS reduces peak temperatures and flattens gradients; combine thermal hardware with firmware throttles and cumulative burst accounting to protect life.

Policy reminder: defer final numeric thresholds to your cell vendor datasheets and validated bench tests. The segmented charging and ramp‑rate controls above are operational patterns you should verify against your pack’s documented limits.

Balancing and SOC/SOH management that protect uptime

Passive vs active balancing

- Passive balancing is simple and effective for small excursions. Active balancing (energy transfer) corrects larger deltas faster and is recommended for high‑cadence fleets where a single weak cell can reduce fleet availability.

Trigger and termination policy examples

- Policy example (tune to your pack): start active energy transfer when ΔV exceeds 50 mV at top‑of‑charge; aim to converge to ≤30 mV before returning the pack to rotation. Balance during top‑of‑charge or rest windows where OCV slope assists convergence and temperatures are stable.

SOC accuracy for LiFePO4’s flat plateau

- LFP’s flat OCV‑SOC curve makes top‑of‑charge anchoring essential. A weekly 100% charge with a 10–15 minute top‑hold helps recalibrate coulomb counters and triggers balancing; log each calibration in your ALM so SOC corrections are auditable.

SOH, rotation and retirement

- Combine capacity retention and DCIR drift in your retirement logic. As an operational starting point, use capacity ≤80% or sustained DCIR growth beyond your validated drift bound as triggers for mission reallocation or decommissioning. Record decisions and the supporting telemetry in the ALM ledger.

Troubleshooting the ERR cluster: over‑temp, imbalance, communications

Over‑temperature alarms

- Symptoms: rapid temperature rise, pronounced cell‑to‑cell gradients, repeated throttles. Immediate actions: reduce load, force cooling, validate heatsink/fan function and thermal interface integrity, and review derating tables. Document the event and thermal time series in ALM for root‑cause linkage.

Cell imbalance handling (the ERR decoder)

- Light imbalance (ΔV = 50–100 mV): initiate the BMS’s built‑in dynamic balancing and allow a minimum 12‑hour resting balance window at the top‑of‑charge to converge cells. If the pack fails to converge within that window, escalate to bench equalization.

- Heavy imbalance (ΔV > 100 mV): require external equalization equipment for repair and do not permit high‑C takeoffs or heavy missions until the pack is restored and validated. Record pre‑ and post‑equalization DCIR and cell voltage vectors in the ALM entry.

Communications deep‑dive (ERR2 and IEC 61850 considerations)

- Don’t stop at loose wiring. For systems using IEC 61850 or similar logical‑node mappings, verify that LD/LN mappings are consistent between ground‑station SCL files and the pack’s SCL/communication configuration. Run an SCL validation through your rules engine or SCL validator to detect mismatched LN names, missing logical devices, or semantic mapping errors that can prevent correct telemetry subscription. For CAN/RS485 links, check termination, shielding, correct bitrate, and adherence to bus spec; use ULog/bus‑analyzer traces to correlate error frames to EMI or software enumeration issues.

A practical decoder mindset

- Classify ERRs as Thermal, Electrical/Protection, Balance/SOC, or Comms. Validate sensors and wiring first, then firmware tables and mapping (SCL/LD/LN), and only then replace hardware. Always capture pre‑fix telemetry and the applied remediation steps in ALM.

Maintenance SOPs that reduce TCO in practice

Weekly cadence

- Controlled 100% charge for LFP packs (10–15 minute top‑hold) to recalibrate SOC and trigger balancing; inspect connectors and mechanical interfaces. Log the calibration timestamp and follow‑up metrics in your ALM.

Monthly cadence

- Clean cooling paths, verify fan/heatsink performance, recheck static ΔV after rest (policy example target ≤10 mV). If instrumentation is available, perform spot DCIR/ACIR checks and log results to detect early drift.

Firmware governance and bench pilots

- Pilot balancing, self‑heating, and high‑C protection firmware updates on instrumented packs with rollback plans. Publish test reports and attach them to ALM entries before fleet‑wide rollout.

Post‑flight cooling and storage

- High‑temp seasons: enforce a post‑flight cooling window—do not charge packs until cell temperatures return to near ambient (typical cooling target: within a few °C of room temperature, operationally often ~1 hour depending on mass and BTMS). Charging hot cells accelerates SEI evolution and can produce cascading degradation.

Long‑term storage (>10 days): hold SOC at 40–60% and store in a shaded, climate‑controlled location between 15–25°C.

Disclosure: Herewin is our product. As an illustrative workflow you can adapt, maintain a per‑pack ALM record with: last full‑charge calibration timestamp, resting ΔV after 30 minutes, hottest‑cell peak during last sortie, and spot DCIR. Use those fields to trigger actions (calibrate if >7 days since last top‑hold; schedule equalization if ΔV >30 mV; bench‑test if DCIR crosses your validated drift bound). This template is vendor‑agnostic and works with packs that expose similar telemetry.

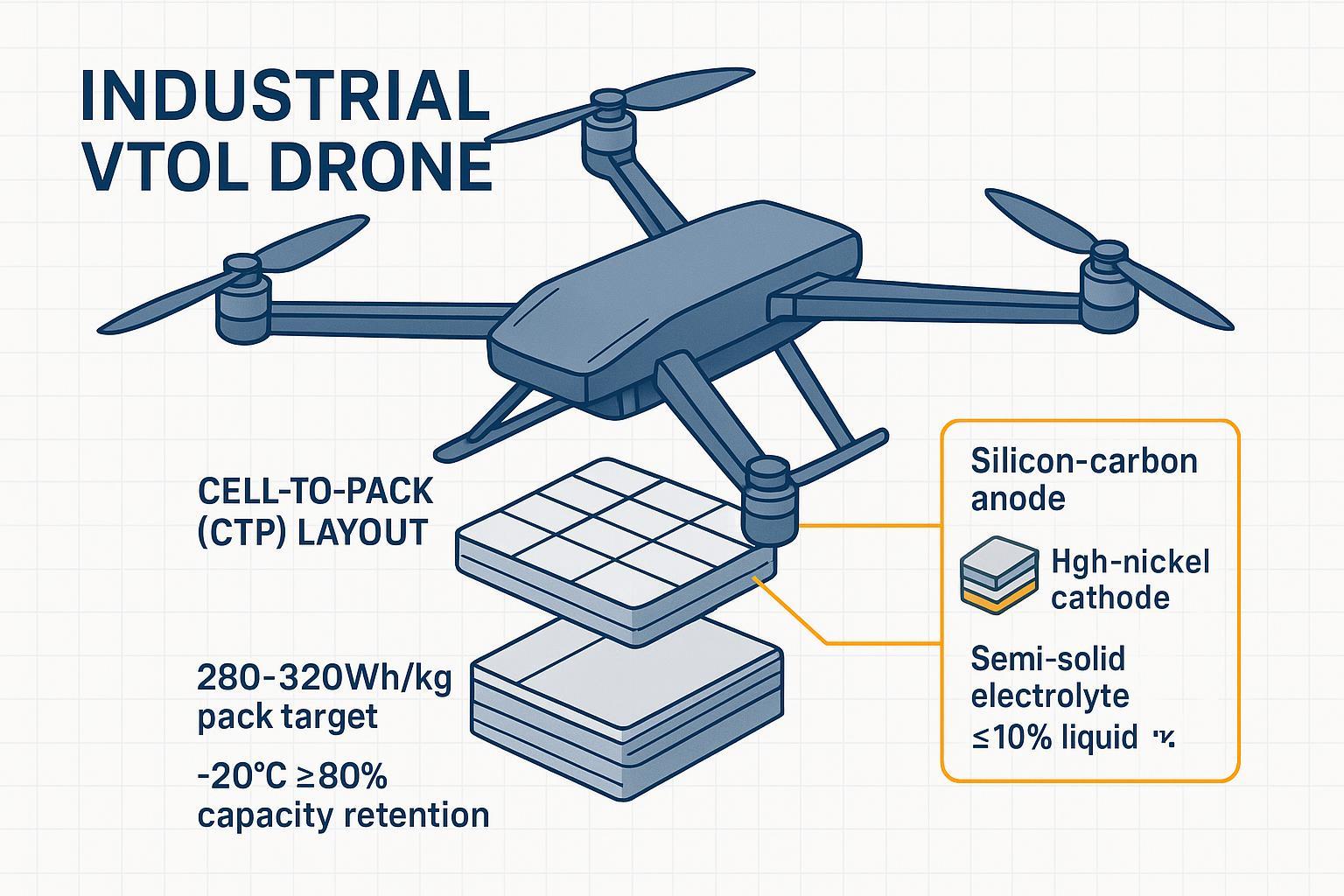

Semi‑solid cells at high C‑rate: core safety strategy (primary focus)

Semi‑solid chemistries change the operating envelope. Where first‑party, audited test data are available, treat those results as the baseline for fleet enablement; where they are not, require bench validation before enabling high‑C modes.

Evidence summary (first‑party, audited datasets)

Herewin’s cleared test summaries are available as vendor datasets and are presented here as vendor‑verified acceptance criteria rather than universal specifications. These results should be used only after you review the underlying test methods and attach the full report to the pack’s ALM entry.

Key Comparative Findings (Vendor Dataset):

- Thermal safety: Approximately a 60% reduction in peak temperature rise was observed in extreme abuse proxies (needle‑puncture and overcharge profiles) compared with conventional liquid‑dominant cells of the same form factor.

- Energy density: Measured uplift in gravimetric energy density, shifting from roughly 250 Wh/kg toward the 300–400 Wh/kg range in the tested semi‑solid formulations.

- Cold performance: Improved low‑temperature retention, with reported ≥80% usable capacity at −20°C and measured discharge power improvements near +25% versus baseline packs.

Operational Note: Treat these numbers as vendor-verified acceptance gates only after you review sensor placement, sample size, ambient control, logging cadence, and analysis methods in the full test report. Do not convert vendor results into fleet standards without conducting your own verification or vendor-coordinated bench campaigns; archive the complete test method and data in the pack’s ALM before enabling high-C operational modes.

Operating policy for enabling high‑C modes

- Gate fast‑charge enablement behind a verification checklist: completed bench campaign with calibrated sensors (≥1 Hz cell‑level logging), acceptable DCIR/ACIR baselines, ramp‑rate profiles within safety envelopes, and a documented rollback plan. Require a staged pilot: single‑pack, benched flights, small fleet pilot, then fleet enablement.

Cold operations advantage and verification

- For extreme‑cold missions, verify vendor data claims with your own preflight validation: instrument a candidate pack, run a −20°C soak, then perform a mission‑profile discharge and compare capacity and peak power to acceptance thresholds. Maintain the validation report in ALM before releasing packs for winter missions.

Archive test methods, equipment, sample counts, and uncertainty bounds. Do not convert first‑party numbers into universal claims; publish them as vendor‑verified acceptance criteria with method attachments.

Mini‑appendix: resistance test overview and an acceptance test checklist

DCIR pulse overview

- At stabilized temperature and defined SoC band, apply a controlled current pulse, rest, and compute DCIR from ΔV/ΔI across the pulse window with polarization correction. Keep test conditions constant so longitudinal trends are comparable; record the method in ALM.

ACIR quick check

- Run a ~1 kHz ACIR snapshot as a rapid solder/weld/contact health check and trend alongside DCIR and capacity.

Acceptance‑test checklist (fill with validated thresholds)

| Item | Method summary | Record fields |

|---|---|---|

| Sensor sanity | Redundant temp sensors, offset checks | ΔT between sensors, pass/fail |

| Balance health | Rest 30 min at top‑of‑charge | ΔV across cells, max/min cell V |

| DCIR baseline | HPPC‑style pulse at controlled temp | ΔV, ΔI, computed DCIR, temp |

| ACIR quick check | ~1 kHz meter | ACIR value, ambient temp |

| Thermal ramp | Step‑load to mission current | °C/min, hottest‑cell peak, ΔT map |

| Comms integrity | Bus termination/bitrate/SCL validation | Bitrate, termination Ω, SCL pass/fail |

Closing and next steps

Treat industrial drone BMS working principles as the backbone of your fleet playbook: accurate measurements, predictable protections, disciplined balancing and SOC calibration, and verification‑led enablement for semi‑solid high‑C operation.Start by:

- Formalizing ALM records to track resistance trends;

- Tightening telemetry accuracy for decision-making;

- Piloting segmented charging and ramp-rate controls in an instrumented fleet.

For extended operational context and procedural templates, consult the Herewin technical team.