Ultra-Long Lifespan Battery

Using a special material formula and process, the cycle life can exceed 3,000 times. The calendar life is significantly extended, reducing the total cost of ownership. This makes it especially suitable for long-term use in applications such as energy storage systems and industrial equipment.

Model: 3.2V 75Ah LFP

Maximum Continuous Discharge: 0.5C

Maximum Continuous Charge: 0.5C

Cycle Life: ≥4000 times

Cell Weight: ~1400g

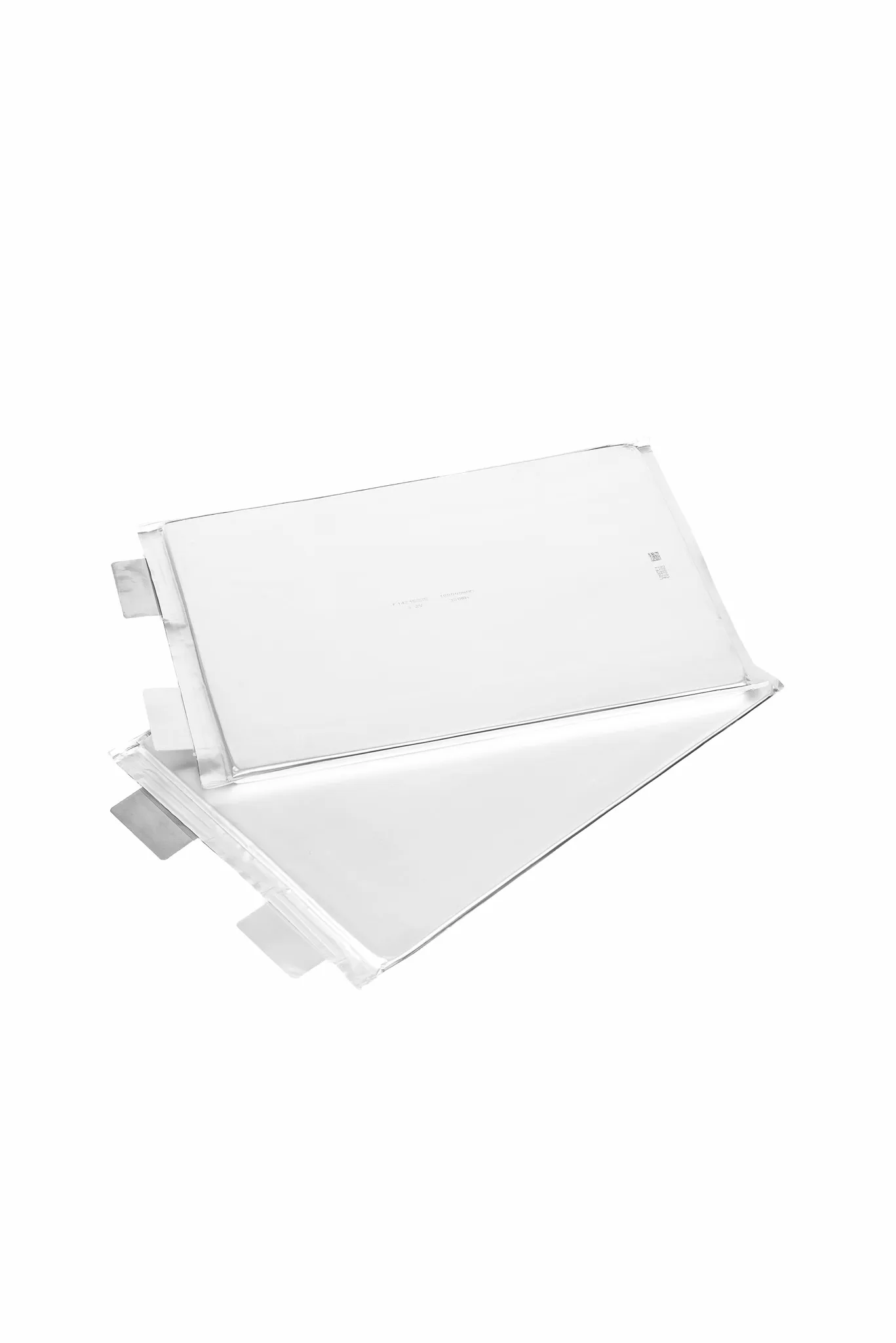

Model: 3.2V 30Ah LFP

Maximum Continuous Discharge: 0.5C

Maximum Continuous Charge: 0.5C

Cycle Life: ≥2000 times

Cell Weight: ~585g

Model: 3.2V 50Ah LFP

Maximum Continuous Discharge: 0.5C

Maximum Continuous Charge: 0.5C

Cycle Life: ≥2000 times

Cell Weight: ~935g

Model: 3.8V 40Ah Cobalt+Ternary

Maximum Continuous Discharge: 20C

Maximum Continuous Charge: 5C

Cycle Life: ≥1000 times

Cell Weight: ~765g

Model: 3.7V 30Ah Ternary

Maximum Continuous Discharge: 5C

Maximum Continuous Charge: 1C

Cycle Life: ≥800 times

Cell Weight: ~400g

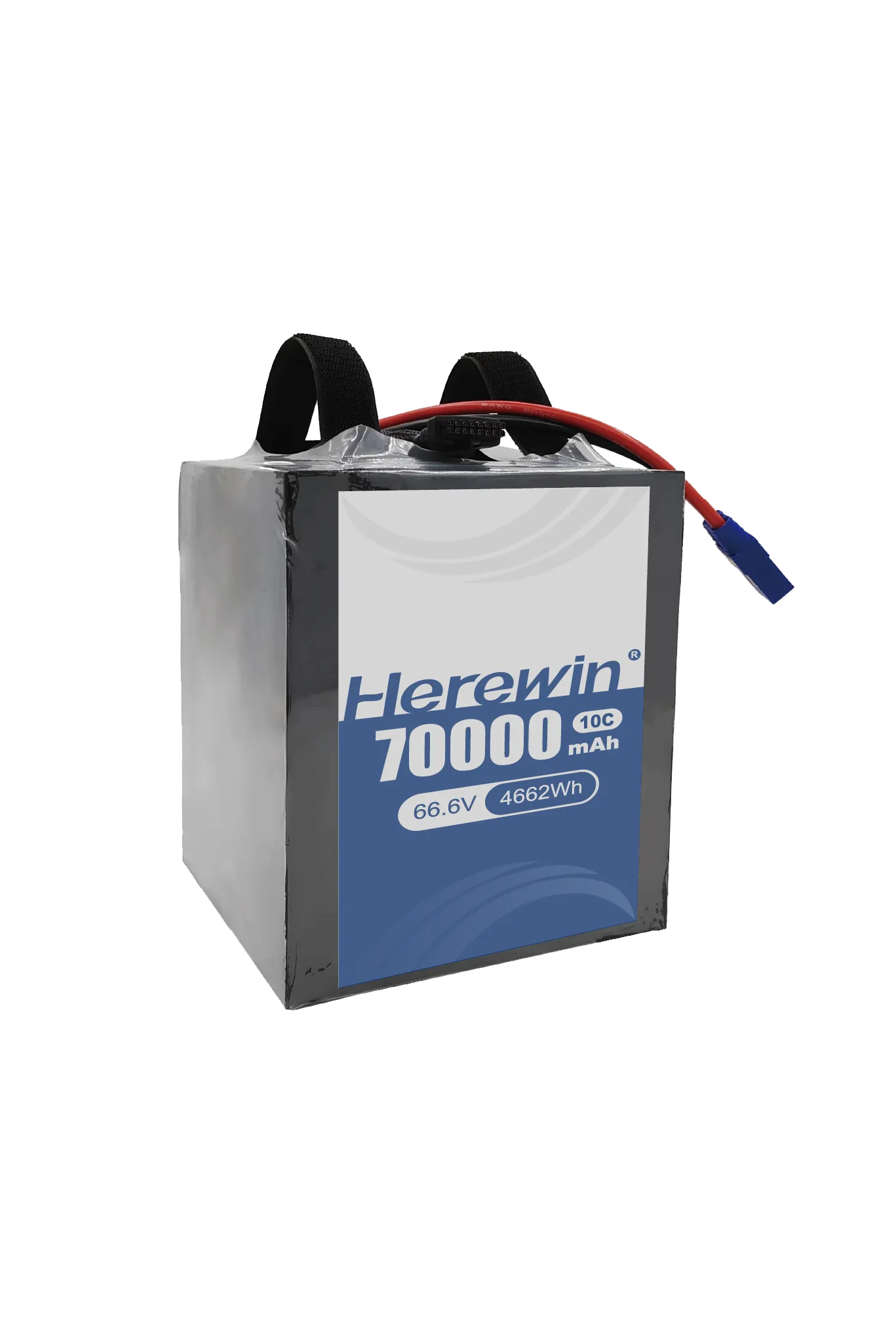

Maximum charging: 1C

Maximum discharging: 10C

Cycle count: ≥800

Weight: 15.08kg

Maximum charging: 1C

Maximum discharging: 10C

Cycle count: ≥800

Weight: 5.88kg

Maximum charging: 1C

Maximum discharging: 10C

Cycle count: ≥800

Weight: 5.83kg

Applications

Ultra-durable batteries perfectly match the long-term operational needs of solar power stations.

High-endurance battery systems designed to handle frequent daily charge-discharge cycles with ease.

Long-cycle batteries ensure 24/7 uninterrupted logistics operations in automated storage environments.

Maintenance-free battery design significantly reduces operating and service costs for fleet operators.

Long-lasting and stable batteries provide reliable nighttime illumination for years with minimal intervention.

Corrosion-resistant, ultra-long-life batteries deliver consistent power to deep-sea monitoring systems over extended deployments.

FREE DESIGN

Customized exclusive battery plans! Professional engineers plan battery programs one-on-one.

Maximize Drone Effect with Our Tailored Battery Solutions

Explore Herewin Factory: The Source of Quality

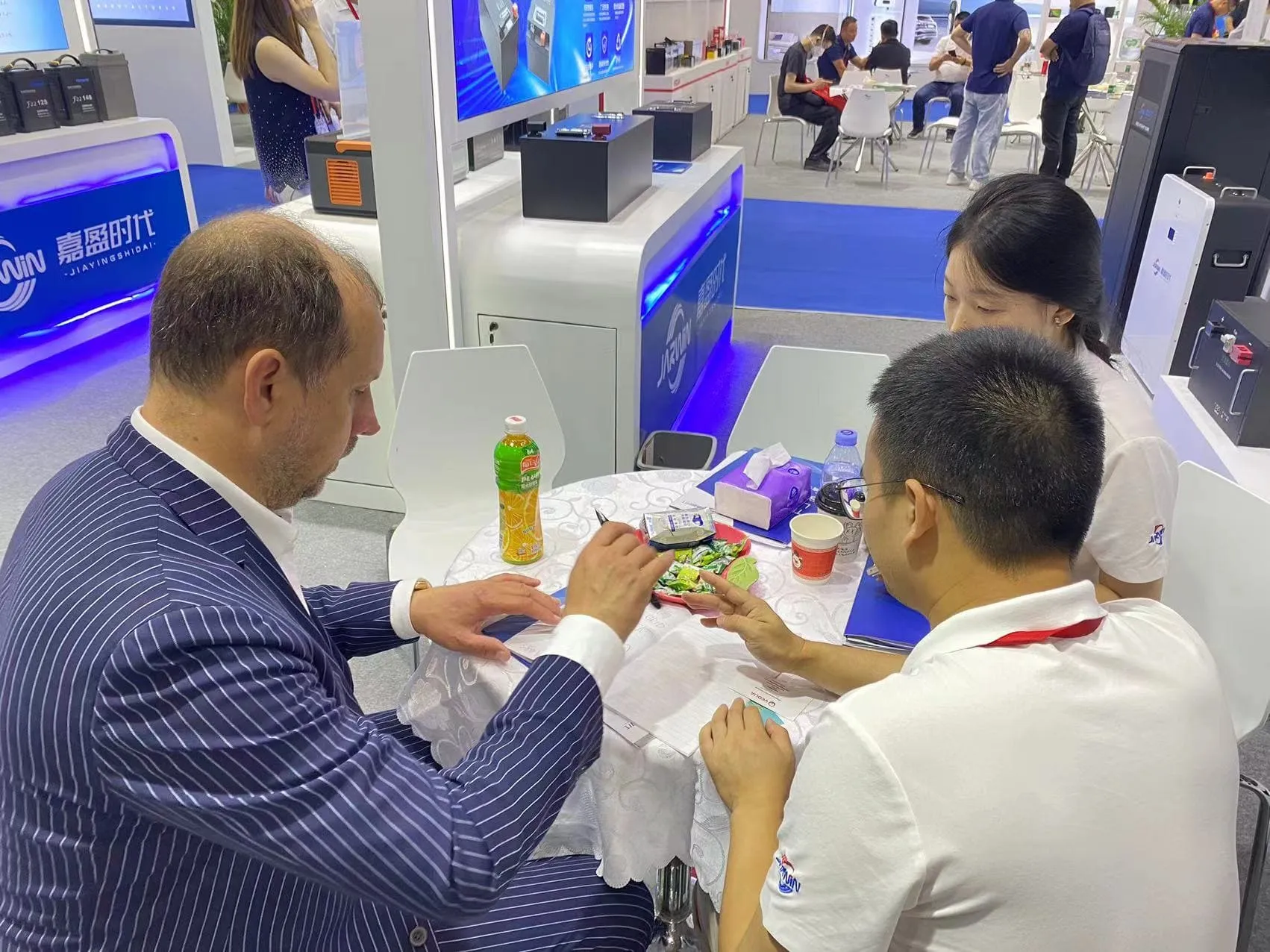

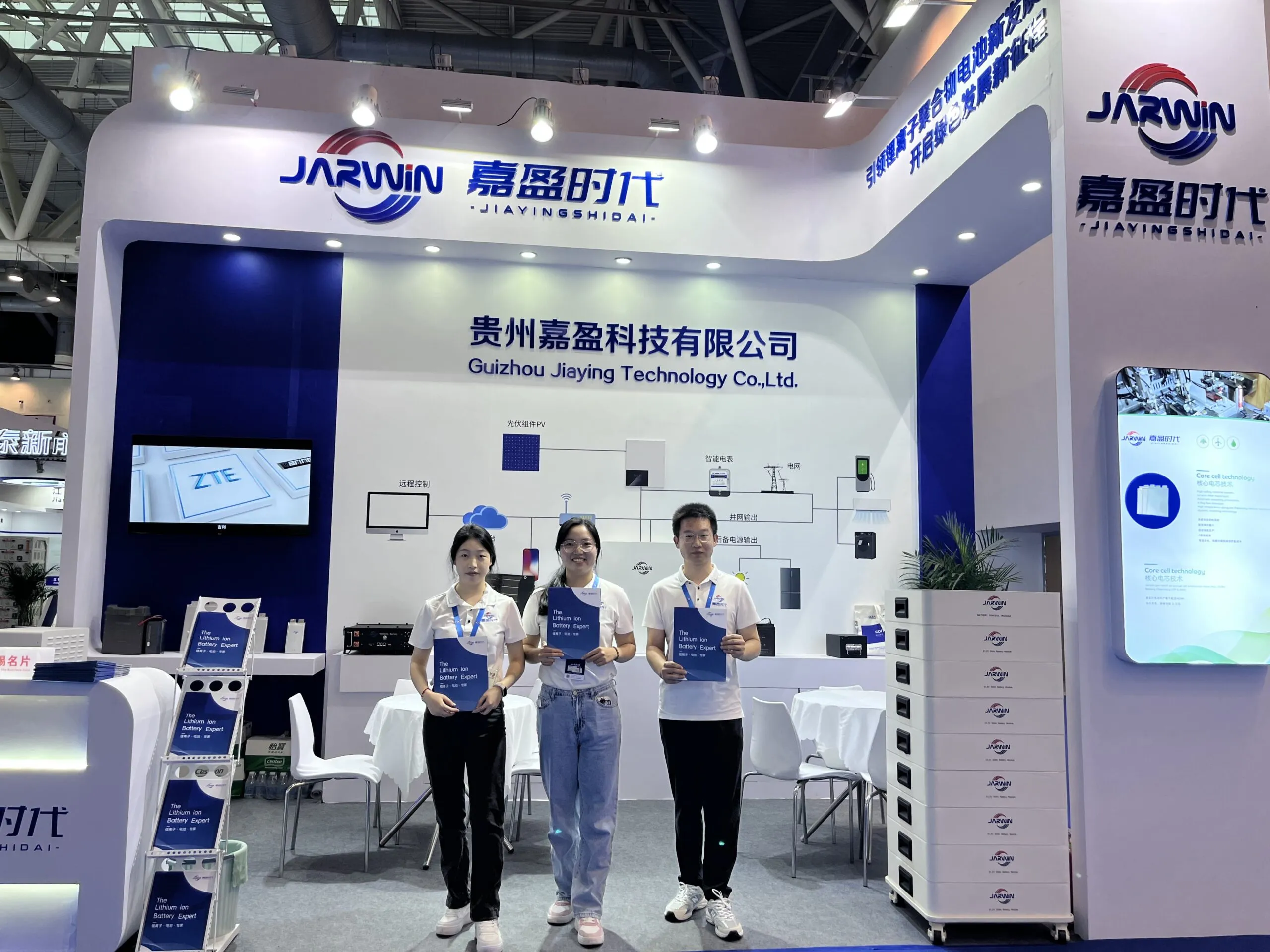

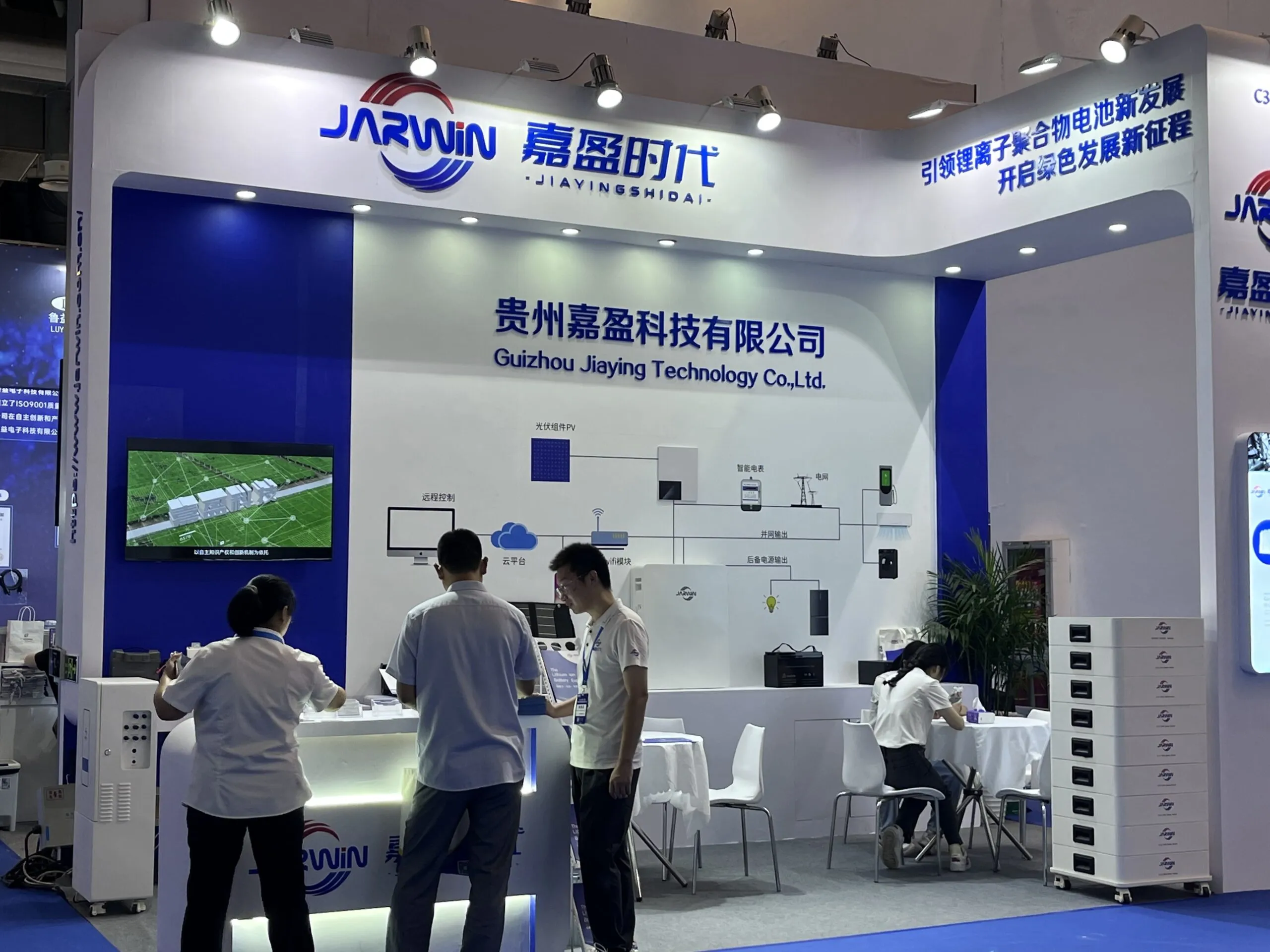

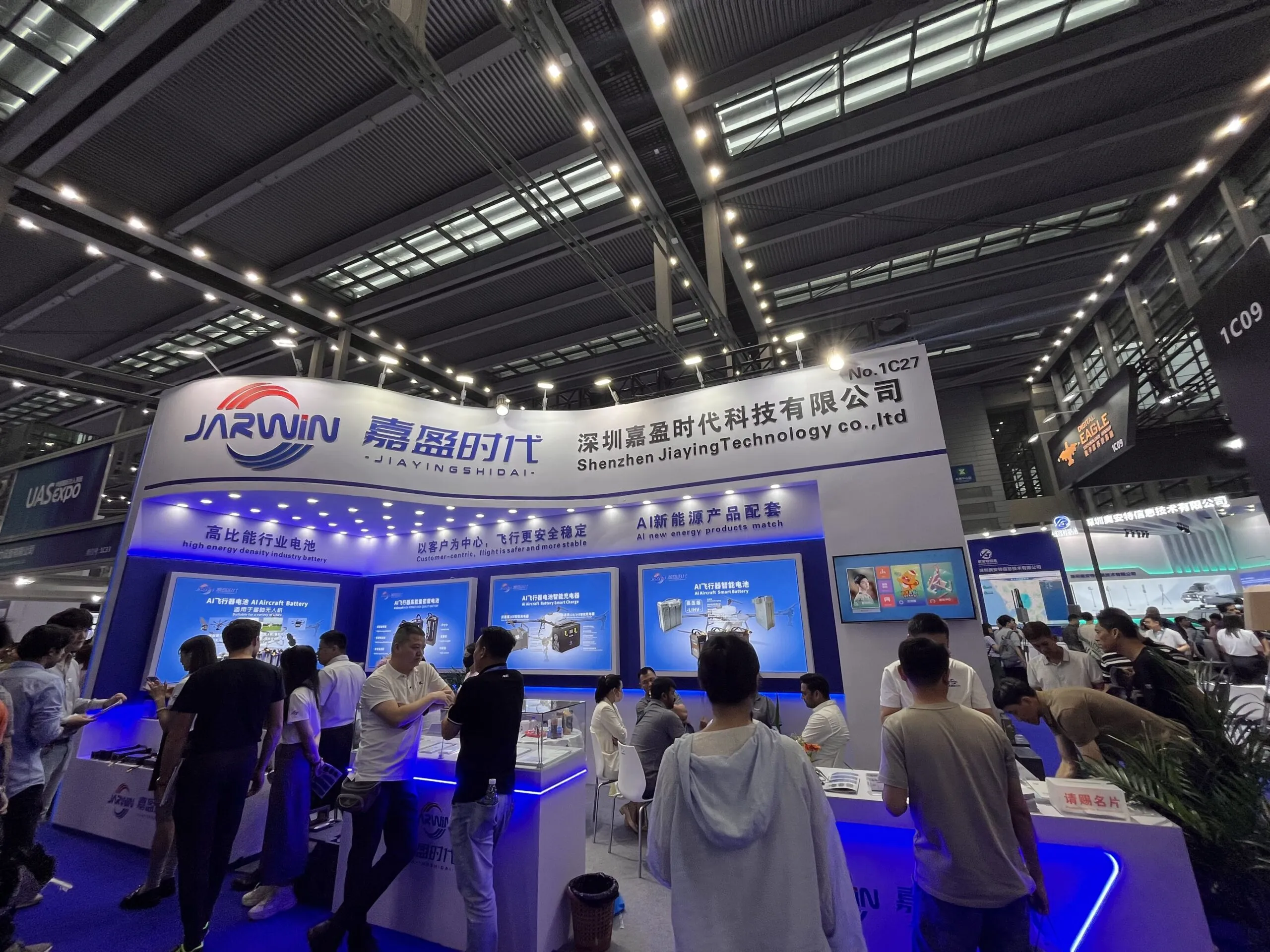

Founded in 2019, Shenzhen Jarwin Time Technology Co., Ltd. is backed by a founding and operational team with over 20 years of extensive experience in the battery industry. It specializes in developing and producing high-performance lithium-ion polymer batteries.

Gain a comprehensive insight into who we are and what we stand for. By exploring the meticulous precision of our

production lines, the efficient management of our factories, and the genuine feedback from our satisfied customers,

you’ll see how we ensure excellence at every step of the process

Different Services For Clients With Different Patterns

FOR OFFLINE CLIENTS

Flexible Delivery Time

Reliable delivery schedules and warehousing support.

High Cost-Effectiveness

Competitive pricing to maximize overall value.

Wide Product Selection

Diverse options to cater to all market segments.

FOR ONLINE CLIENTS

Low MOQ

Flexible MOQ with mixed product options.

Custom Logo

Personalized logo customization for small batches.

One-Stop Marketing Package

Provide quality images, videos to enhance sales revenue.

FOR BRAND CLIENTS

Exclusive Regional Rights

Provide all of herewin's resources and capabilities

R&D Resources

Custom sample within 7 days with R&D capabilities.

Fast Delivery

Efficient production and ship within 25 days at the fastest.

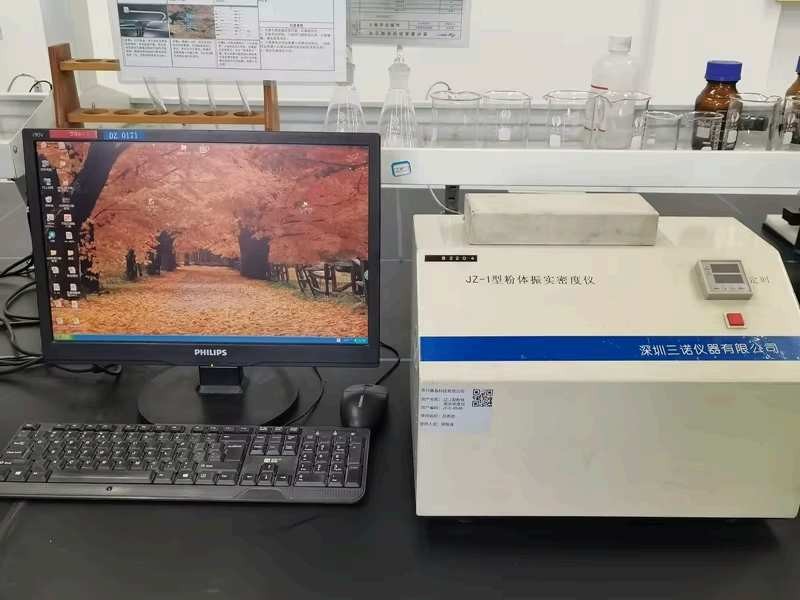

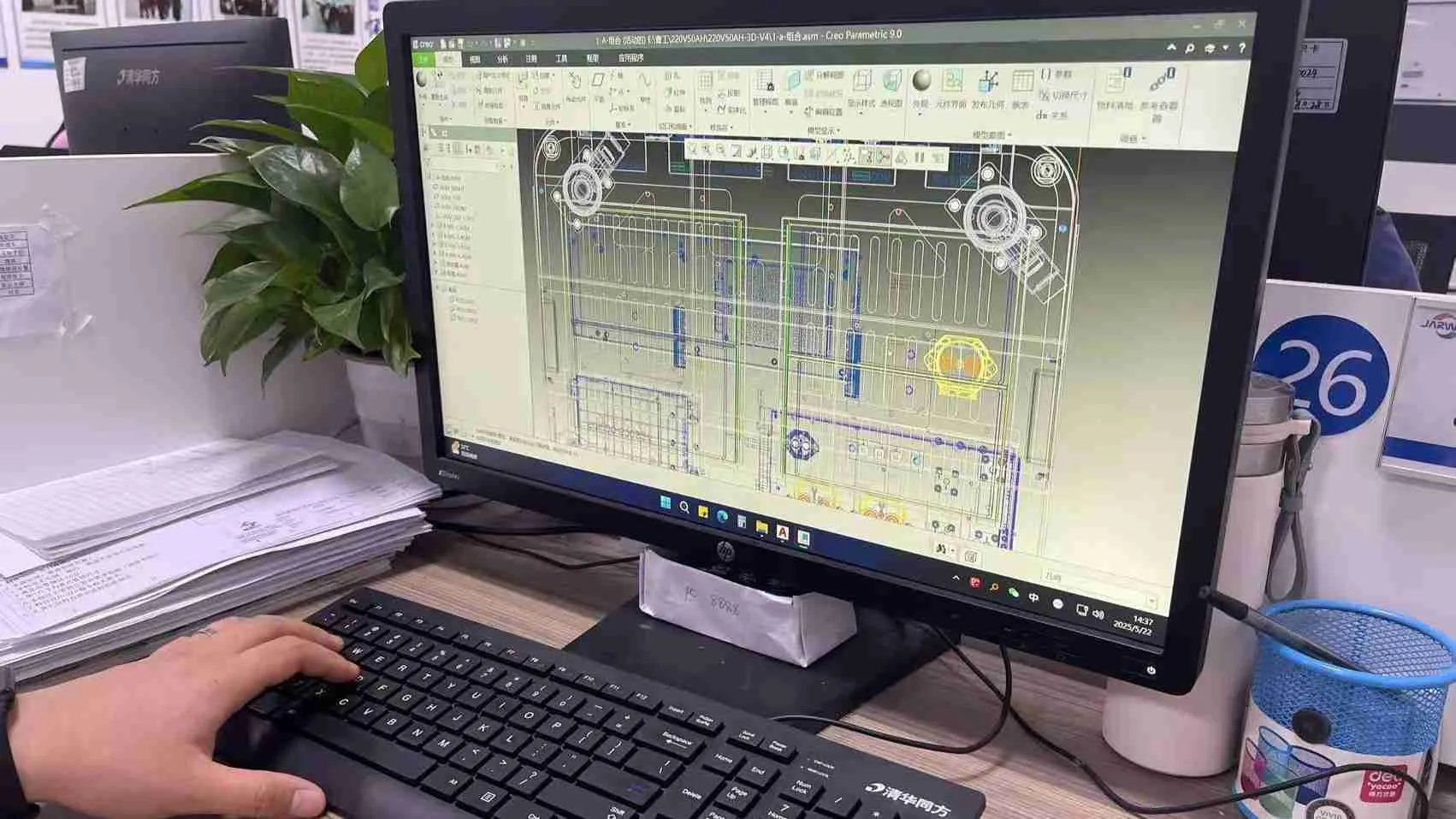

Production Flow of Semi-solid State Battery

Active materials, conductive agents, and binders are uniformly dispersed in solvent to form electrode slurry.

Homogenized slurry is coated onto aluminum foil and dried to form electrode sheets.

Coated electrodes are compressed to specified thickness under controlled pressure.

Post-calendering electrodes undergo vacuum drying to remove residual moisture.

Electrode sheets are precision-cut to required dimensions.

Anodes, cathodes, and separators are stacked in “Z” configuration to form cell cores.

Multi-layer electrode tabs are aligned, ultrasonic-welded, and insulated with adhesive tape.

Cell cores are housed in pre-formed aluminum laminate pouches with top/seal side sealing.

Final moisture removal from assembled cells prior to electrolyte filling.

Precise injection of electrolyte solution into dry cells.

Initial closure of electrolyte injection port.

Electrochemical activation to establish Solid Electrolyte Interphase (SEI) layer on anode.

Gas pocket removal and hermetic terminal sealing.

Charge-discharge cycling for capacity measurement and performance binning.

Validates capacity, impedance, and safety (e.g., overcharge, short-circuit) under strict protocols.

Integrates cells into modules or packs with BMS, wiring, and thermal management systems.

LEARN MORE DETAIL

Learn more about production details and manufacturing process

Testing Process

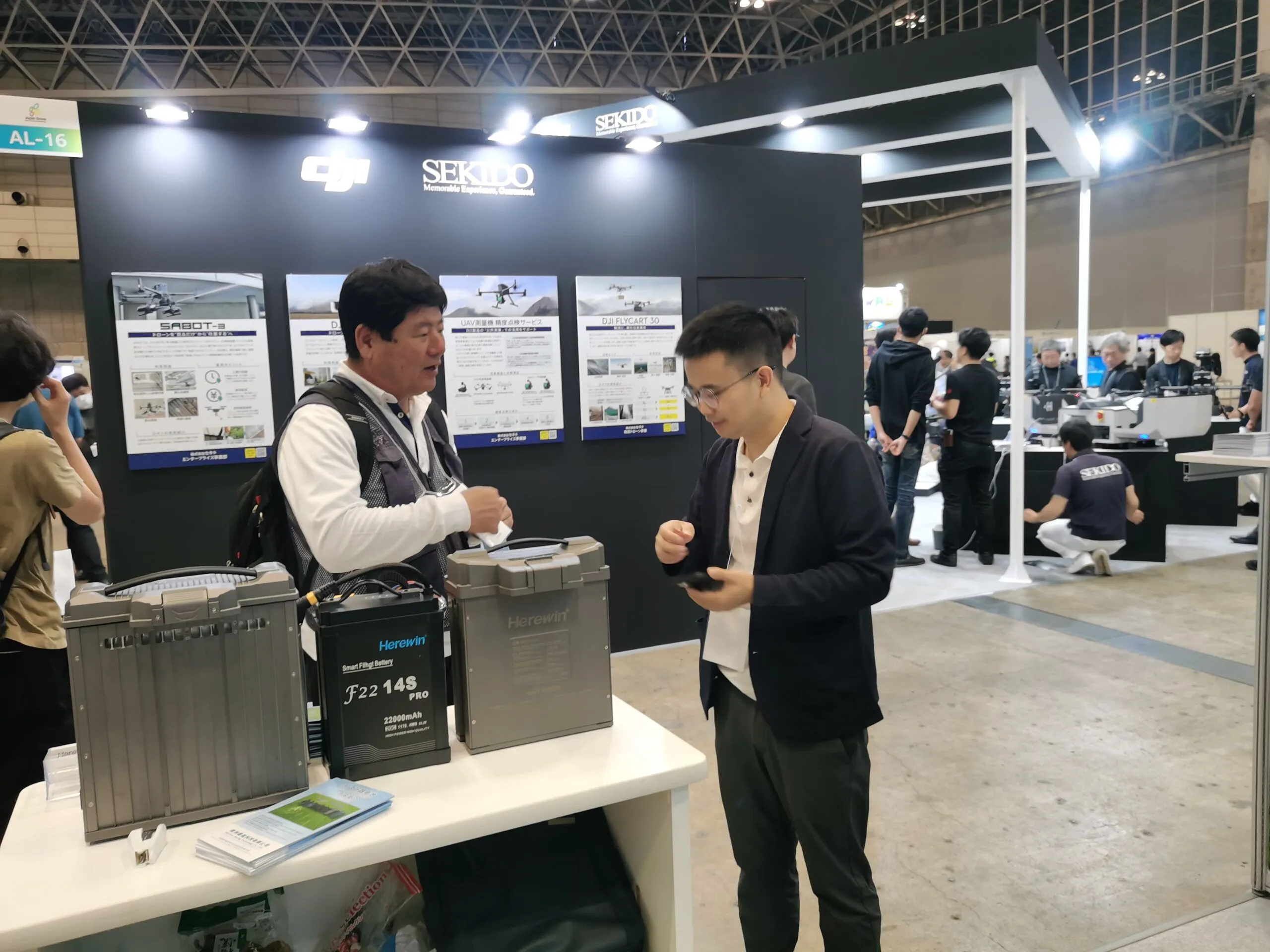

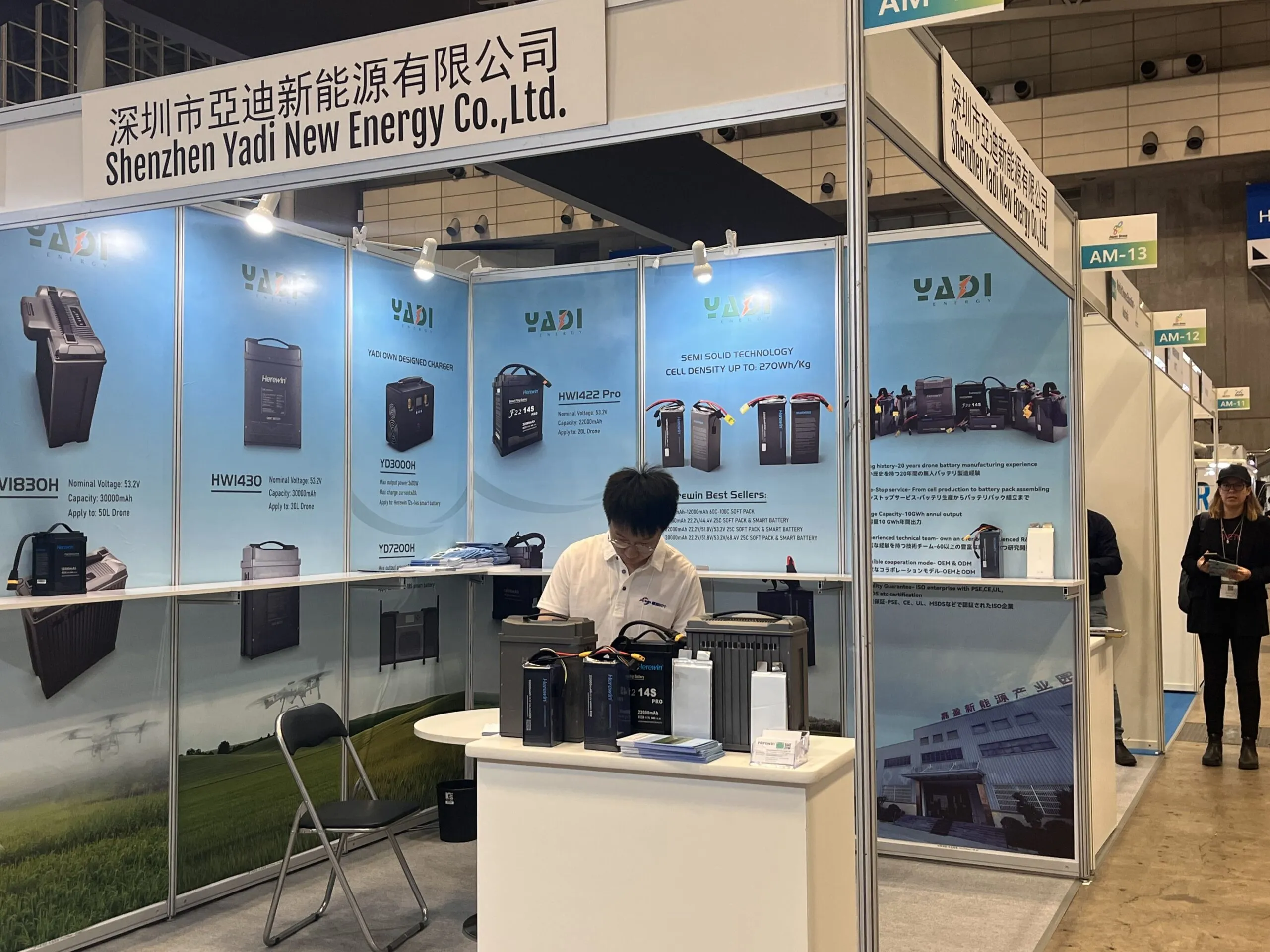

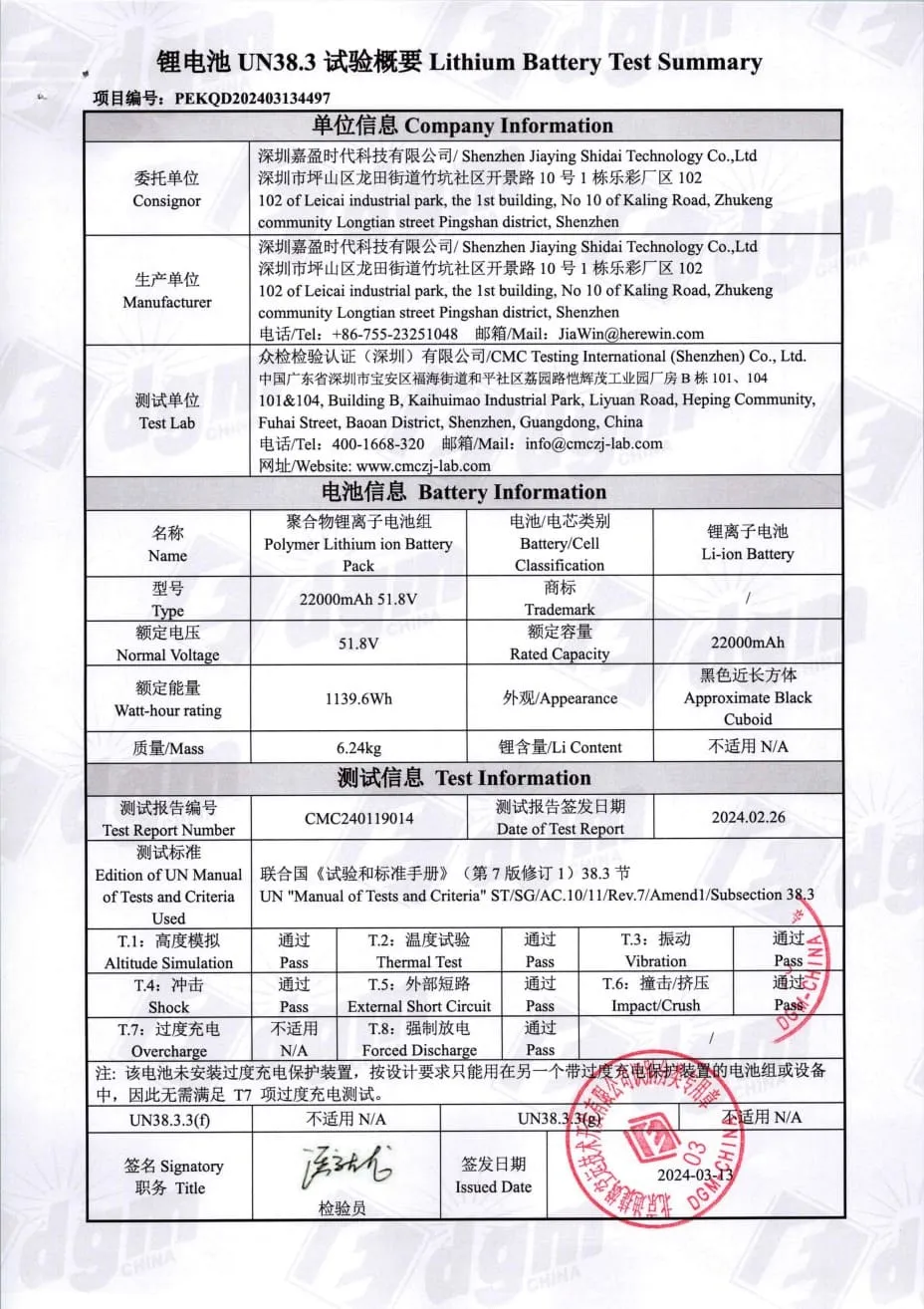

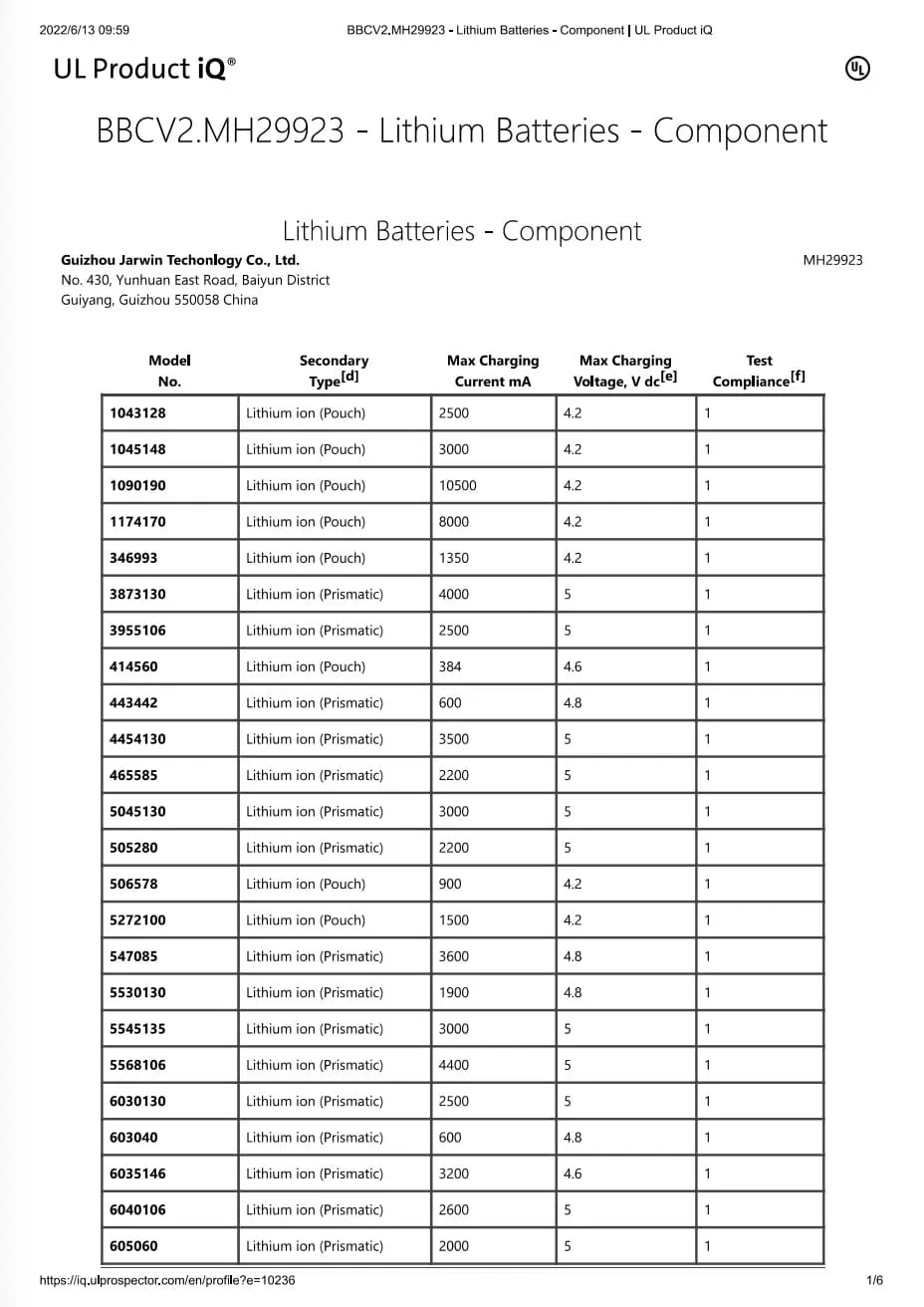

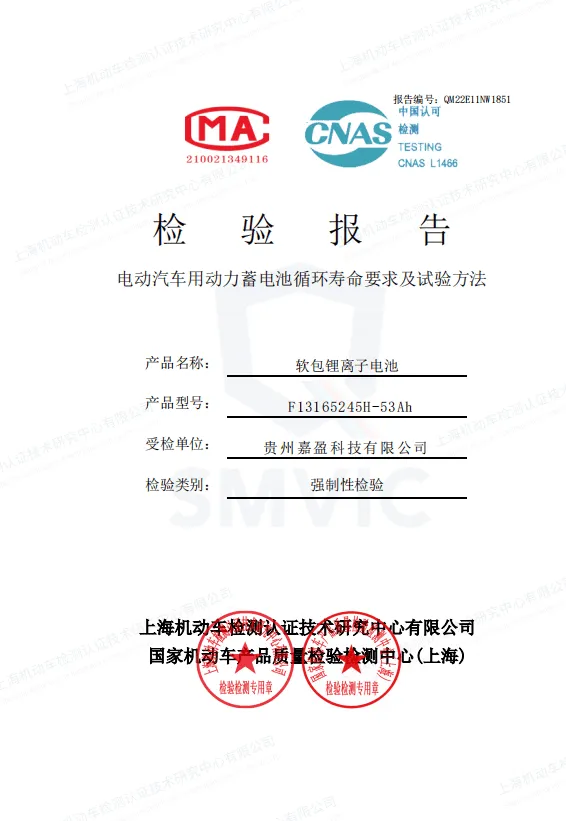

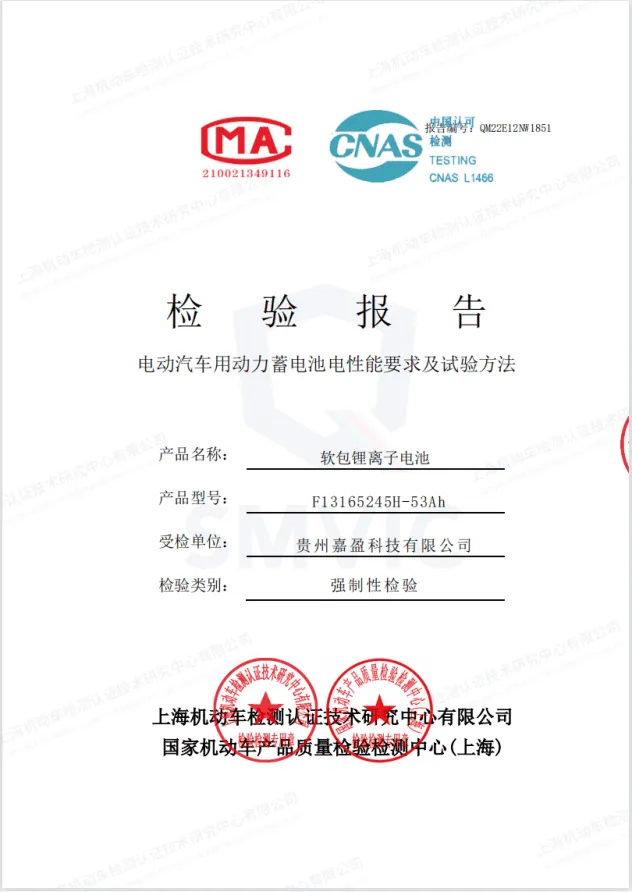

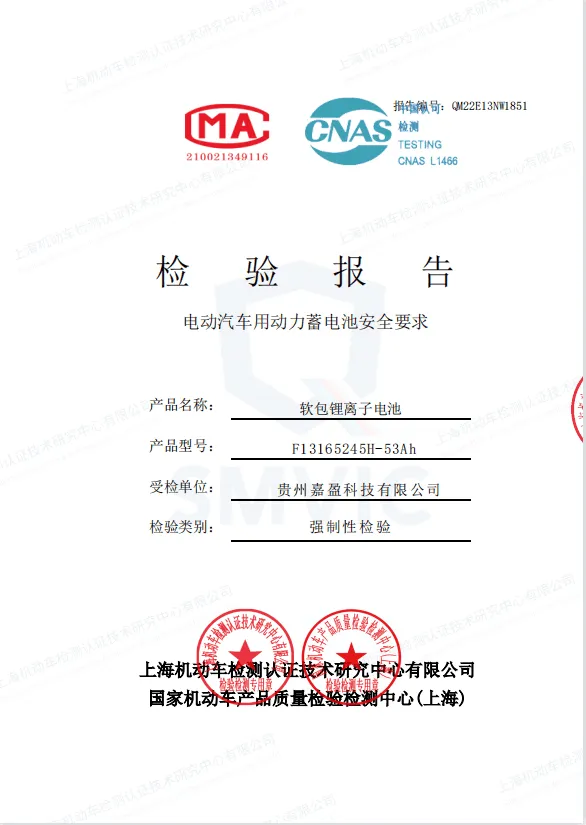

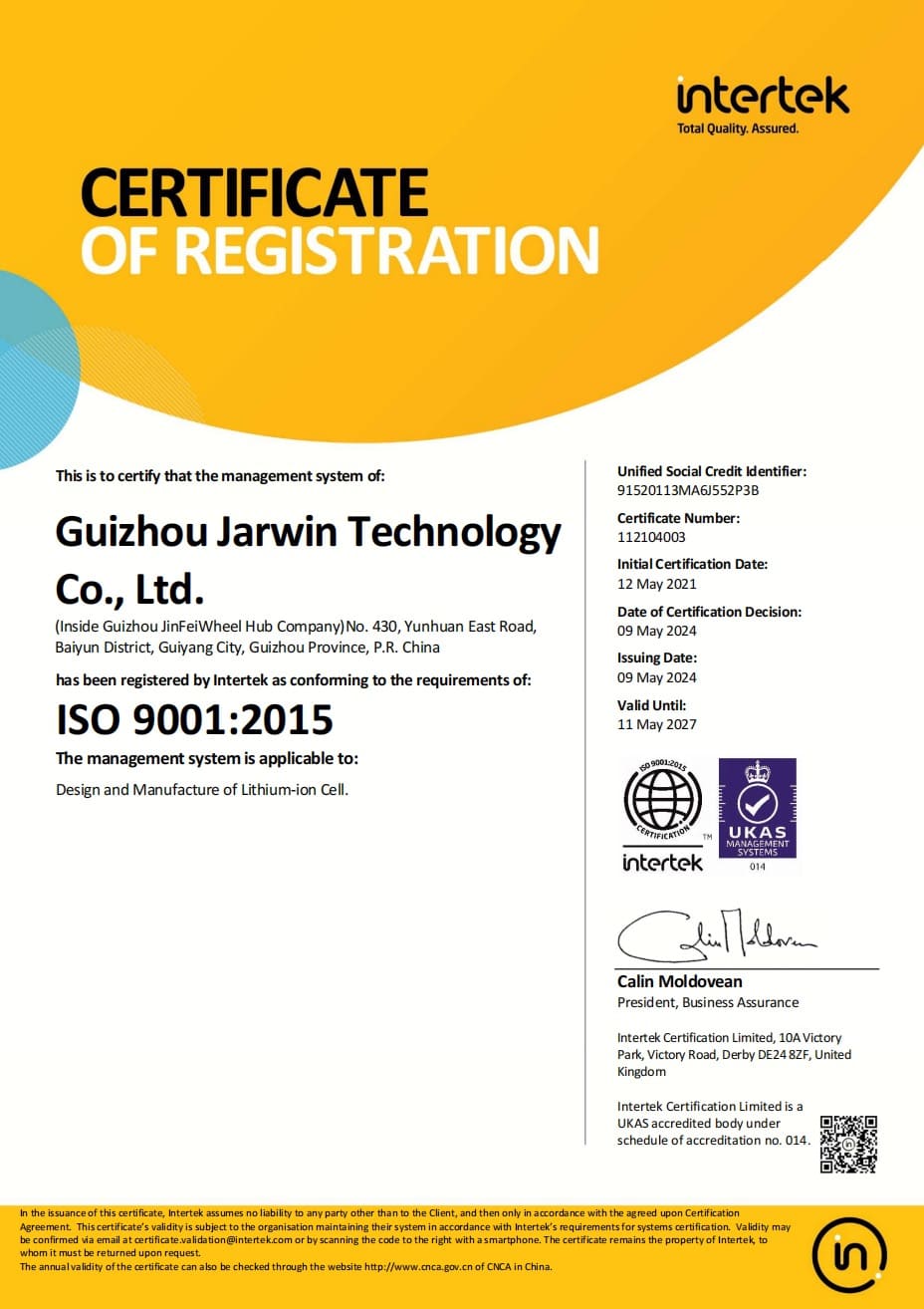

Fair&Certification

Certifications are herewin’s greatest strength.

Meets the needs of all markets, and the source factories are fully certified to ensure quality.

GET IN TOUCH

Want to know what credentials your market needs? Contact me to send you a high resolution image

FAQs

Due to more complex materials and production processes, semi-solid-state batteries currently cost more than traditional liquid cells. However, costs are expected to decline as the technology matures.

Not in the short term. Semi-solid-state batteries are seen as a transitional technology and will likely coexist with liquid batteries across various applications. In the long run, they serve as a stepping stone toward fully solid-state batteries.

Related Blog

Battery selection is a mission‑critical decision for agricultural drone fleets: the wrong chemistry or inadequate sealing reduces flight duration, limits […]

Industrial mapping teams live and die by endurance, reliability, and data quality. For operators of Platform composite-wing or heavy‑lift multirotors, […]

If you operate a logistics fleet, your battery is more than a component—it affects airtime availability, operational risk, and cross-border […]

Lithium Iron Phosphate (LiFePO4) batteries have become the preferred power source for energy storage, electric vehicles, and portable devices, thanks […]

As the “power core” of drones, lithium batteries directly determine flight stability, endurance, and safety. However, issues like reduced capacity, […]

Our New Catalogue

Learn more about Semi-solid batteries, and the full range of products