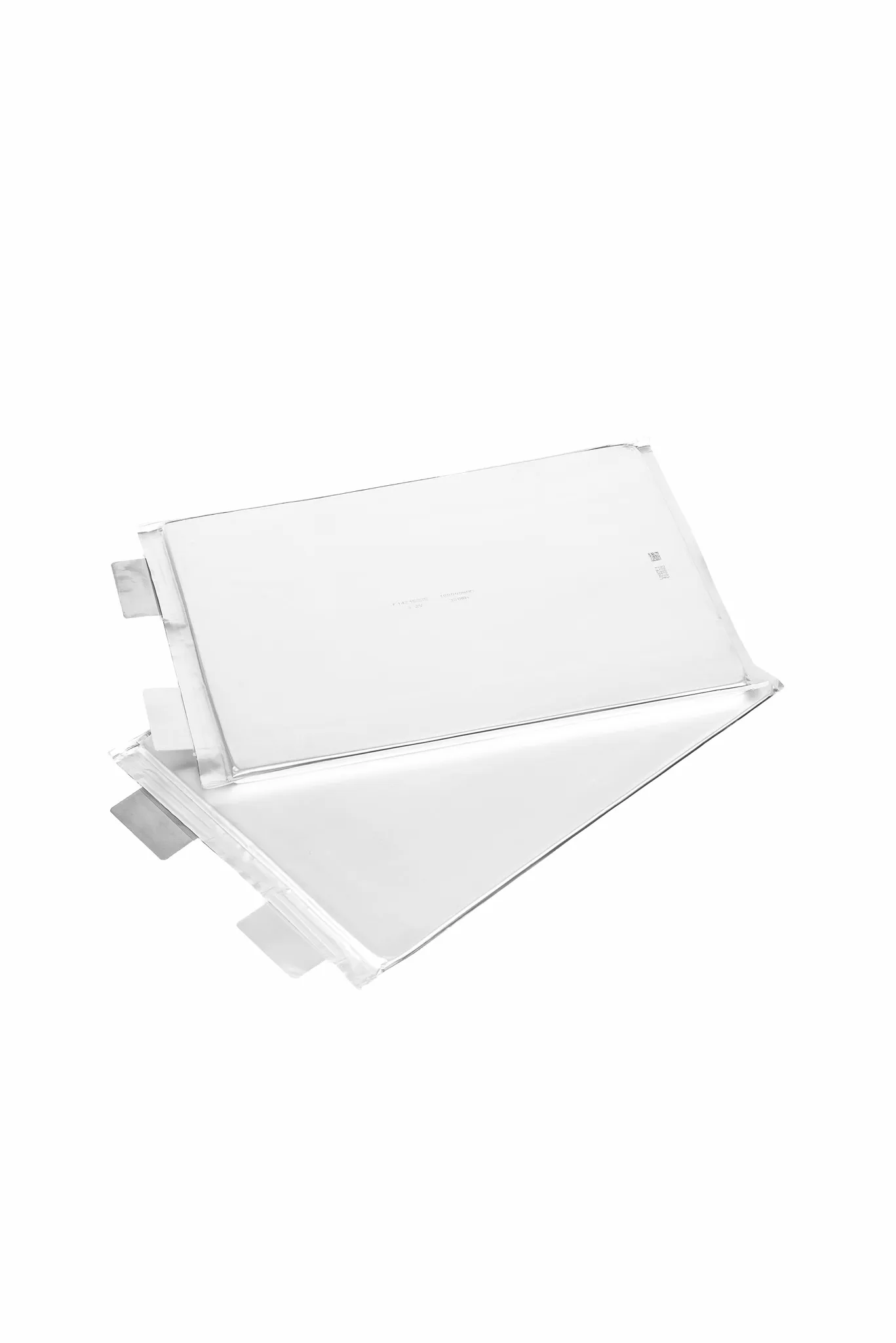

Batterijcellen

Battery cell is the smallest energy unit of the battery system, realizing the storage and release of electric energy through electrochemical reactions. Its performance directly determines the energy density, life and safety of the battery module and system, which can be categorized into lithium ternary (NCM/NCA), lithium iron phosphate (LFP), lithium cobalt oxide (LCO), Lithium manganese iron phosphate(LTO) and other types according to the material system.

Model: 3,7V 26Ah Ternary

Maximale continue ontlading: 5C

Maximale continue oplading: 1C

Het cyclusleven: ≥800 keer

Celgewicht: ~310g

Model: 3.8V 40Ah Cobalt+Ternary

Maximum Continuous Discharge: 20C

Maximum Continuous Charge: 5C

Cycle Life: ≥1000 times

Cell Weight: ~765g

Model: 3.8V 30Ah Cobalt+Ternary

Maximum Continuous Discharge: 20C

Maximum Continuous Charge: 5C

Cycle Life: ≥1000 times

Cell Weight: ~545g

Model: 3.8V 22Ah Cobalt+Ternary

Maximum Continuous Discharge: 20C

Maximum Continuous Charge: 4C

Cycle Life: ≥600 times

Celgewicht: ~395g

Model: 3.8V 20Ah Cobalt+Ternary

Maximum Continuous Discharge: 20C

Maximum Continuous Charge: 4C

Cycle Life: ≥600 times

Cell Weight: ~380g

Maximum continuous discharge: 0.5C

Maximum continuous charging: 0.5C

Cycle life: ≥ 1500 times

Cell weight:~1850g

Maximum continuous discharge: 0.5C

Maximum continuous charging: 0.5C

Cycle life: ≥ 2000 times

Cell weight:~940g

Maximum continuous discharge: 0.5C

Maximum continuous charging: 0.5C

Cycle life: ≥ 1500 times

Cell weight:~855g

Toepassingen

Crop spraying operations requiring extended flight time, fast charging, and support for frequent takeoffs/landings in high-intensity environments.

Environmental monitoring, security patrols, or equipment checks; requires weather-resistant operation and persistent endurance.

Stores solar/grid power for household use, prioritizing safety and stable long-term charge/discharge cycles.

Replaces lead-acid batteries for longer runtime and rapid charging in warehouse logistics.

High-density battery cells provide longer range and ultra-fast charging to optimize EV efficiency and quickly replenish power.

GRATIS ONTWERP

Op maat gemaakte exclusieve batterijplannen! Professionele technici plannen batterijprogramma's één-op-één.

Maximaliseer het effect van je drone met onze batterijoplossingen op maat

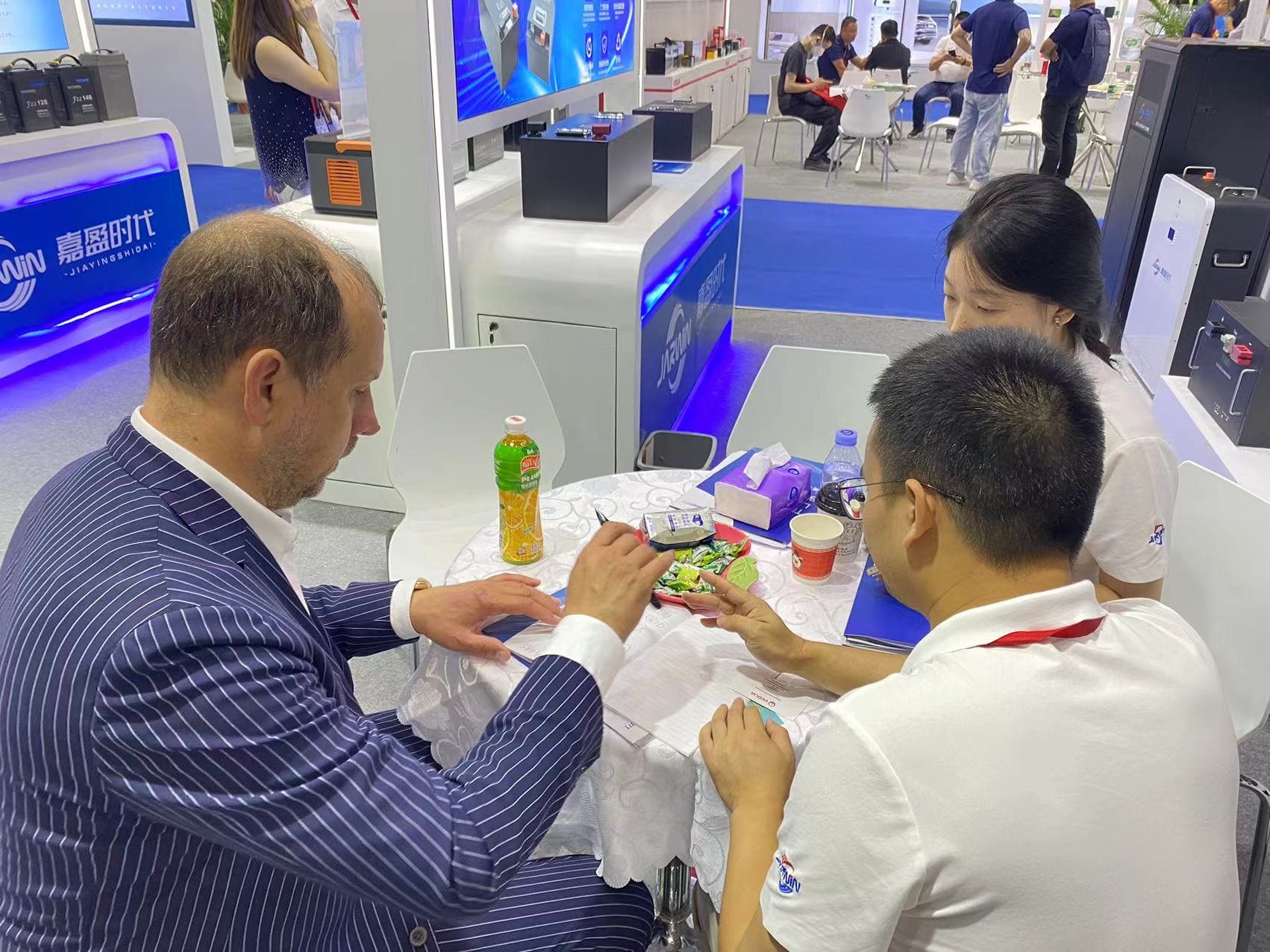

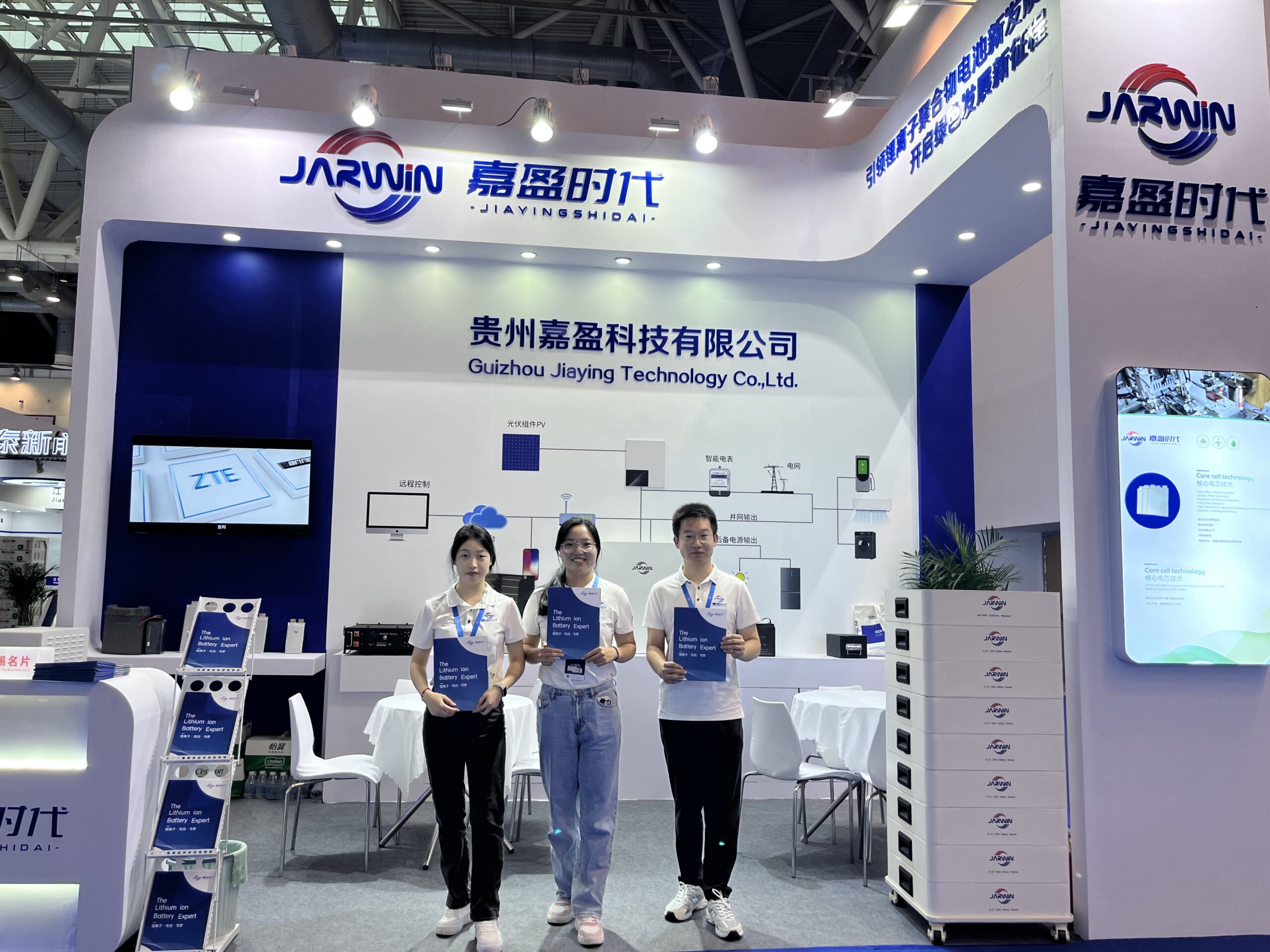

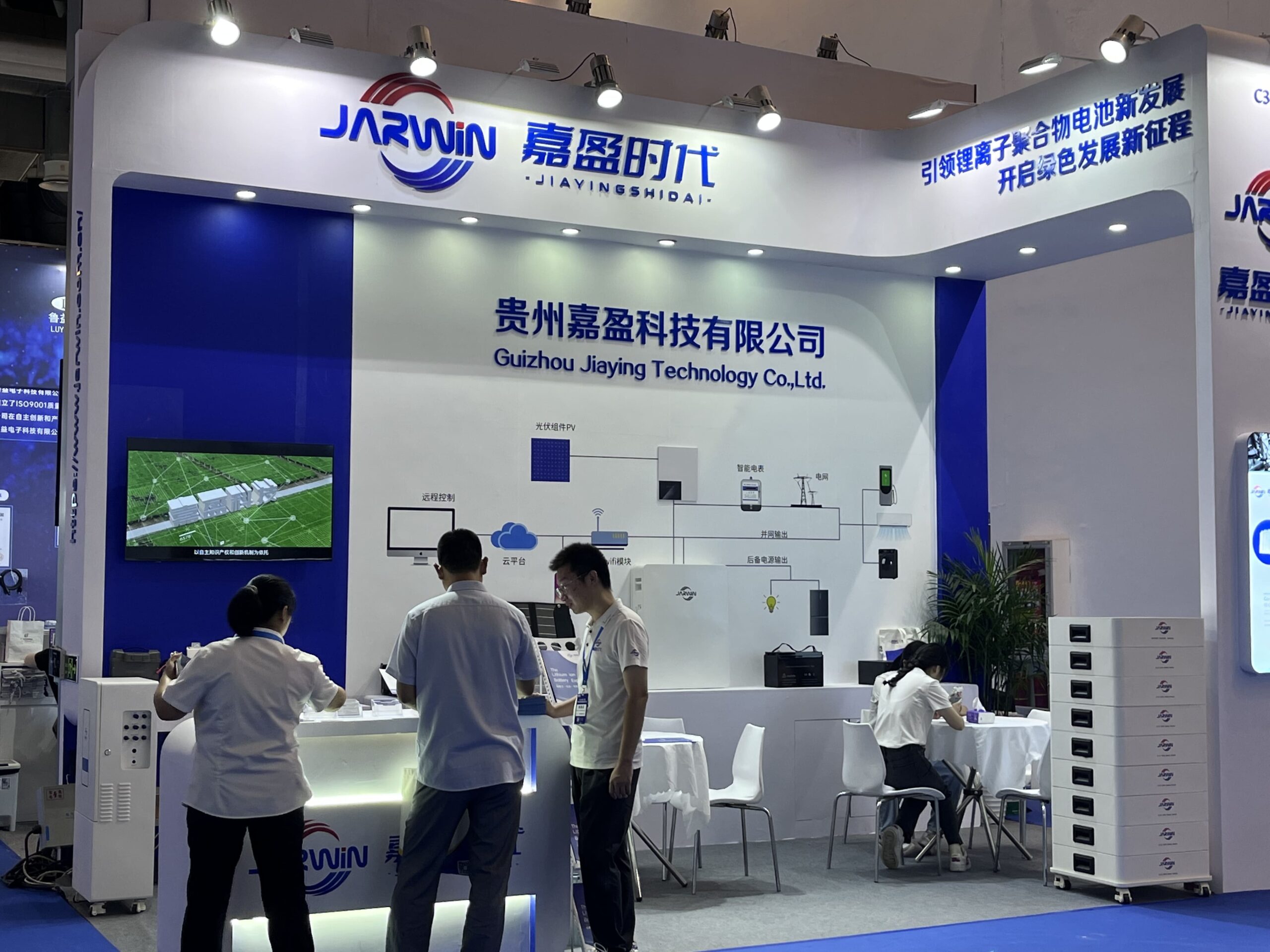

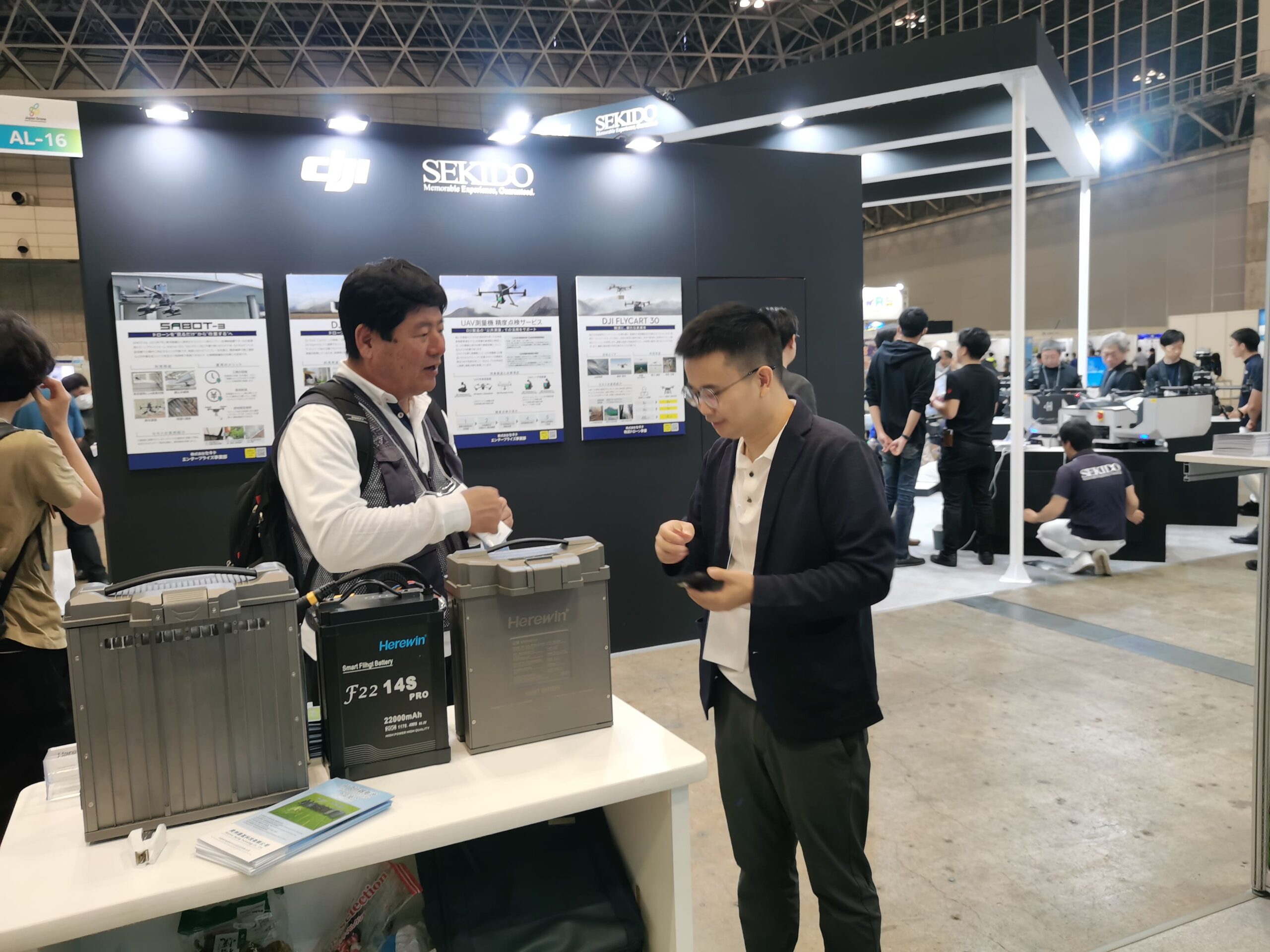

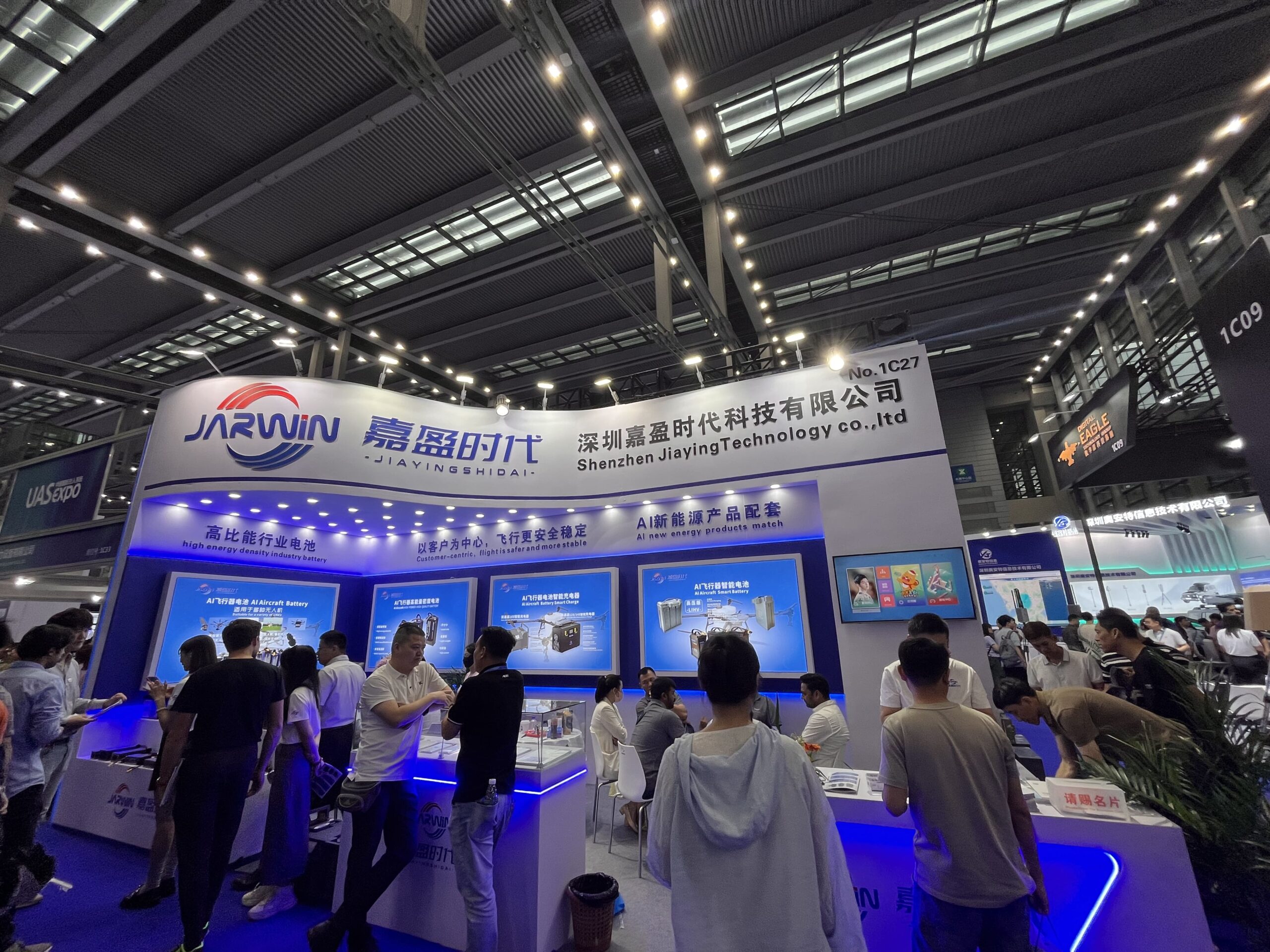

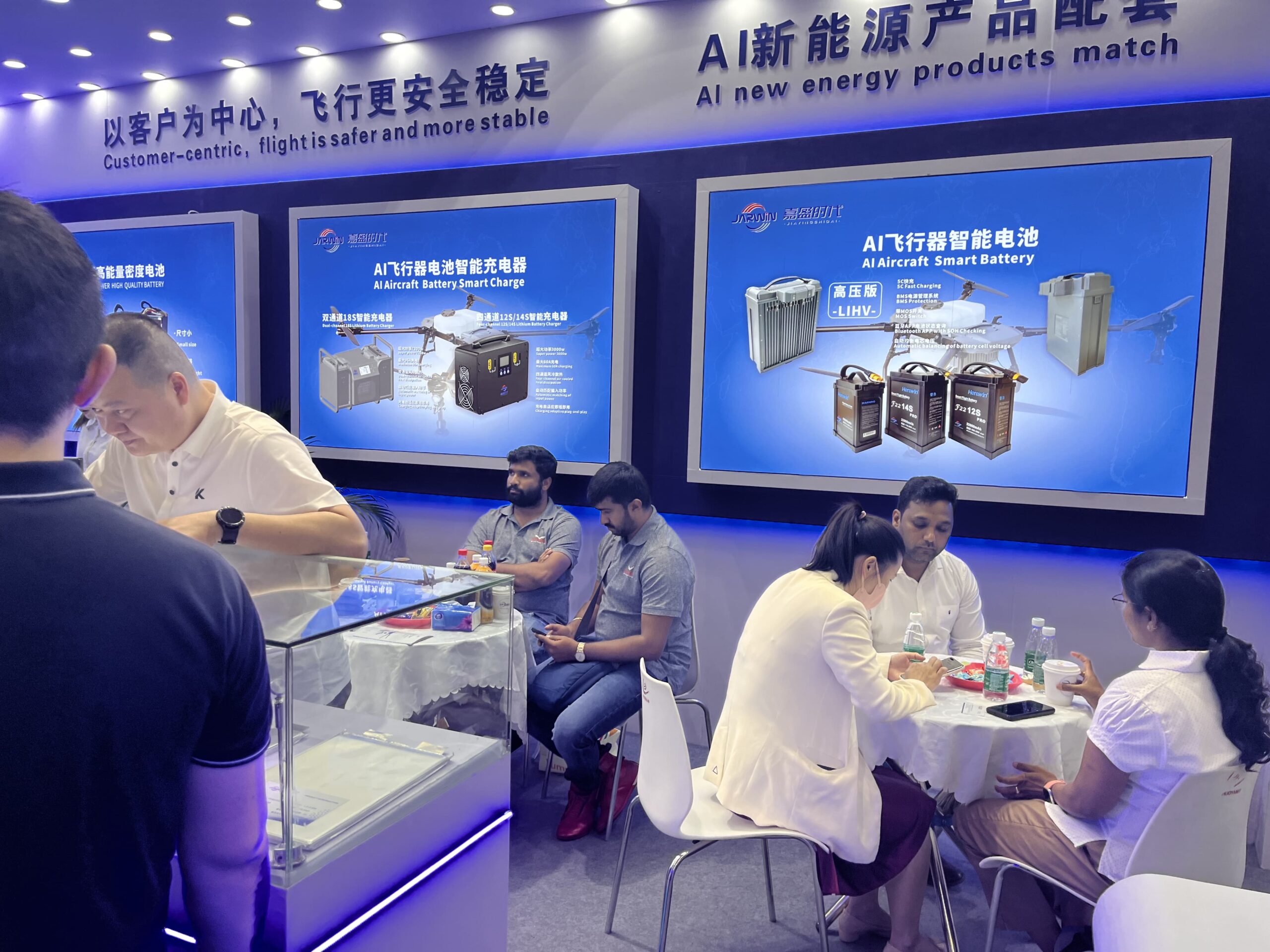

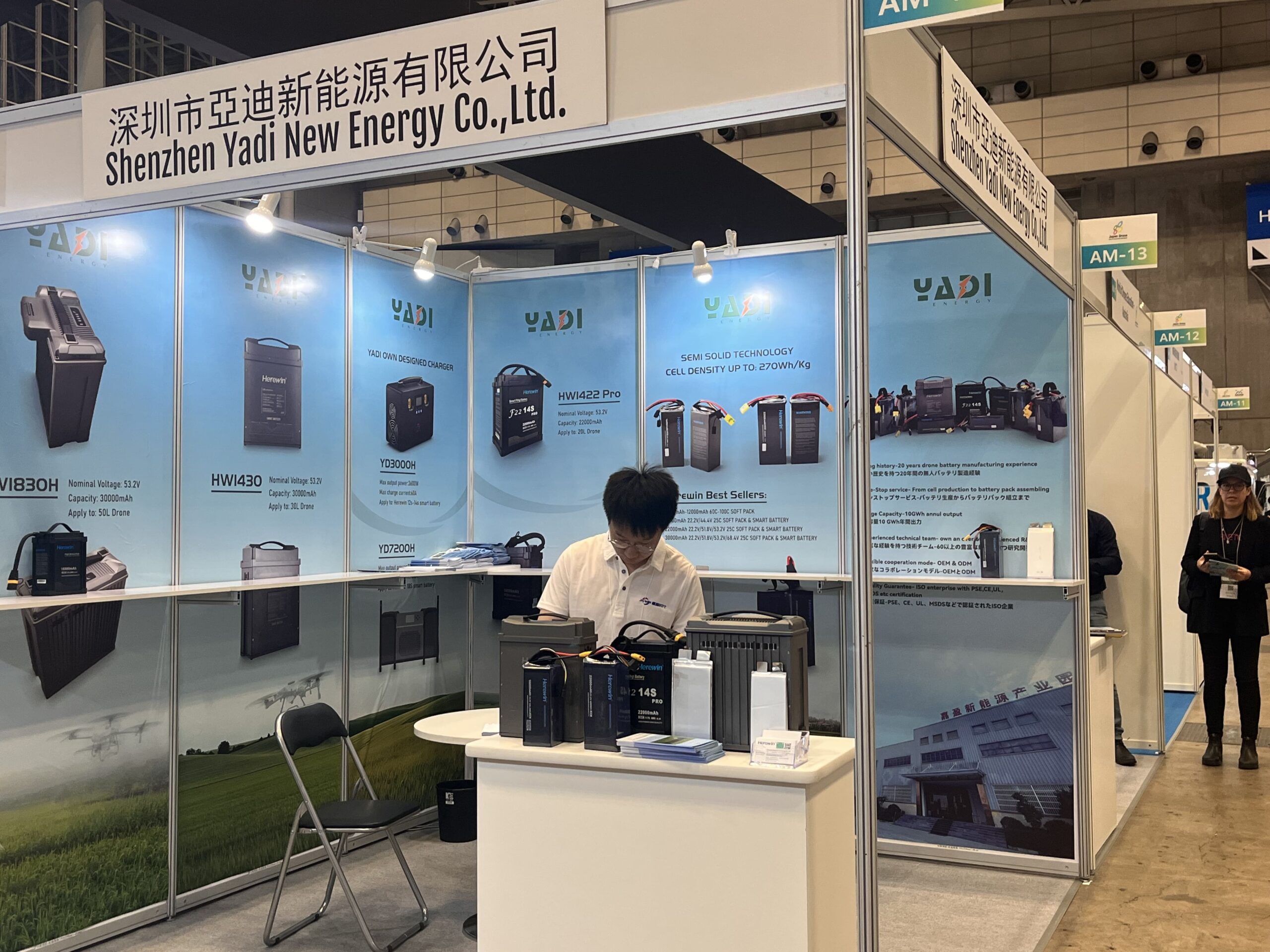

Ontdek de Herewinfabriek: De bron van kwaliteit

Shenzhen Jarwin Time Technology Co, Ltd is opgericht in 2019 en wordt ondersteund door een oprichtings- en operationeel team met meer dan 20 jaar uitgebreide ervaring in de batterij-industrie. Het bedrijf is gespecialiseerd in de ontwikkeling en productie van hoogwaardige lithium-ion-polymeerbatterijen.

Krijg een uitgebreid inzicht in wie we zijn en waar we voor staan. Door de nauwgezette precisie van onze

productielijnen, het efficiënte beheer van onze fabrieken en de oprechte feedback van onze tevreden klanten,

zie je hoe we uitmuntendheid garanderen bij elke stap van het proces

Verschillende services voor klanten met verschillende patronen

VOOR OFFLINE KLANTEN

Flexibele levertijd

Betrouwbare leveringsschema's en ondersteuning bij opslag.

Hoge kosteneffectiviteit

Concurrerende prijzen om de totale waarde te maximaliseren.

Uitgebreide productselectie

Diverse opties voor alle marktsegmenten.

VOOR ONLINE KLANTEN

Laag MOQ

Flexibele MOQ met gemengde productopties.

Aangepast logo

Persoonlijke aanpassing van logo voor kleine batches.

Alles-in-één marketingpakket

Zorg voor kwaliteitsafbeeldingen en video's om de verkoopopbrengst te verhogen.

VOOR MERKKLANTEN

Exclusieve regionale rechten

Alle middelen en mogelijkheden van herewin ter beschikking stellen

R&D Resources

Custom sample within 7 days with R&D capabilities.

Snelle levering

Efficiënte productie en verzending binnen 25 dagen op zijn snelst.

Production Flow of Battery Cells

Blends active materials, binders, and solvents into a uniform slurry to ensure consistent electrochemical performance.

Spreads the slurry onto metal foils (anode/cathode) with precise thickness control for optimal energy density.

Removes solvents from coated electrodes to stabilize material adhesion and prevent cracking.

Combines anode/cathode layers with separators and winds them into a compact jellyroll structure.

Compresses electrodes to enhance density and conductivity while maintaining porosity for ion flow.

Trims electrodes into precise dimensions to fit battery cell specifications.

Aligns anode/separator/cathode layers in a Z-fold pattern to maximize space efficiency.

Joins electrode tabs using laser welding to minimize resistance and ensure current stability.

Seals cells in aluminum-plastic film to protect against moisture, dust, and mechanical stress.

Removes residual moisture from cells under vacuum to prevent electrolyte degradation.

Fills electrolyte into cells to enable ion transport between electrodes.

Activates cells with initial charging to form a stable solid-electrolyte interface (SEI).

Evacuates gas from cells to eliminate air pockets and ensure full electrolyte penetration.

Cycles cells to stabilize performance and screen out defects before final assembly.

Valideert capaciteit, impedantie en veiligheid (bijv. overladen, kortsluiting) volgens strikte protocollen.

Integreert cellen in modules of pakketten met BMS, bedrading en systemen voor thermisch beheer.

MEER INFORMATIE

Meer informatie over productiedetails en het productieproces

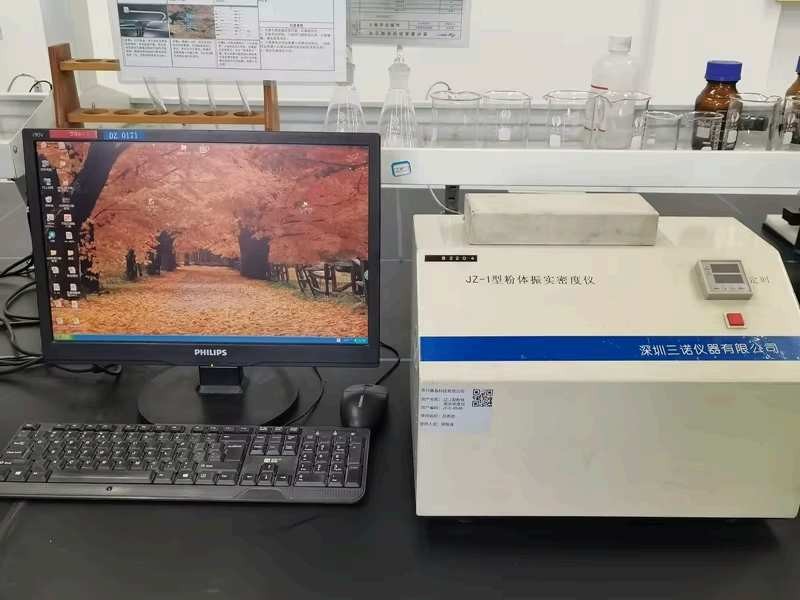

Testproces

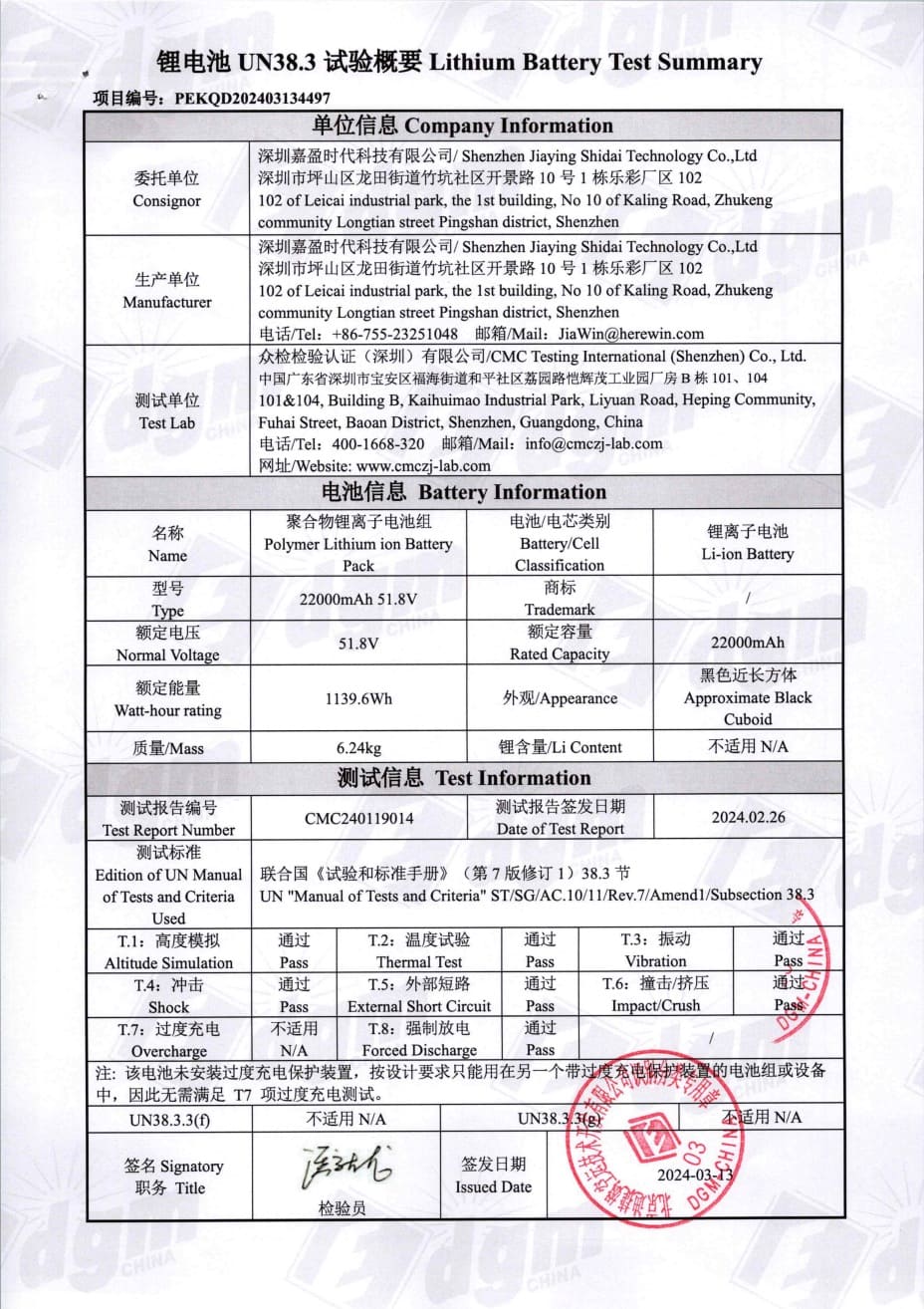

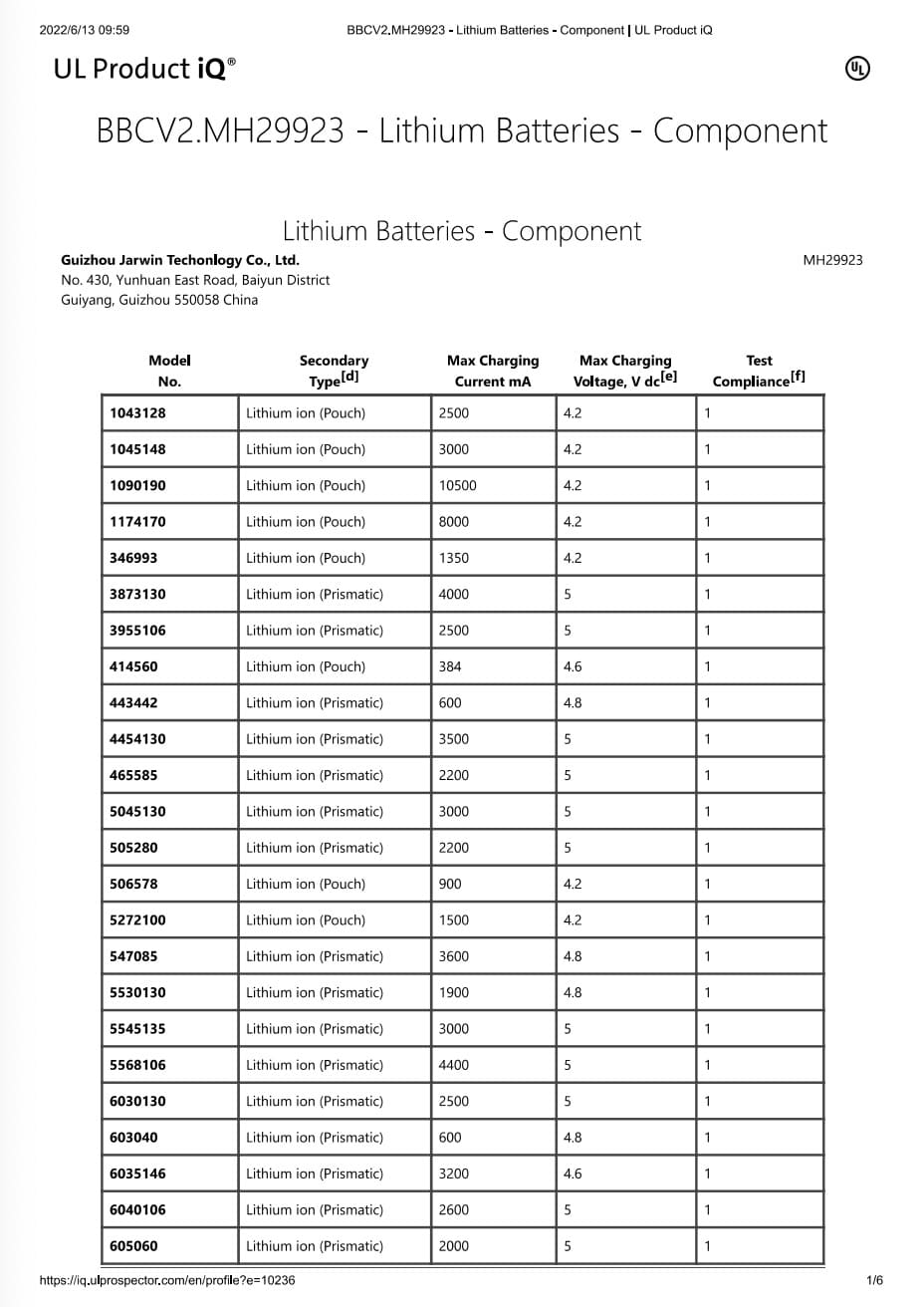

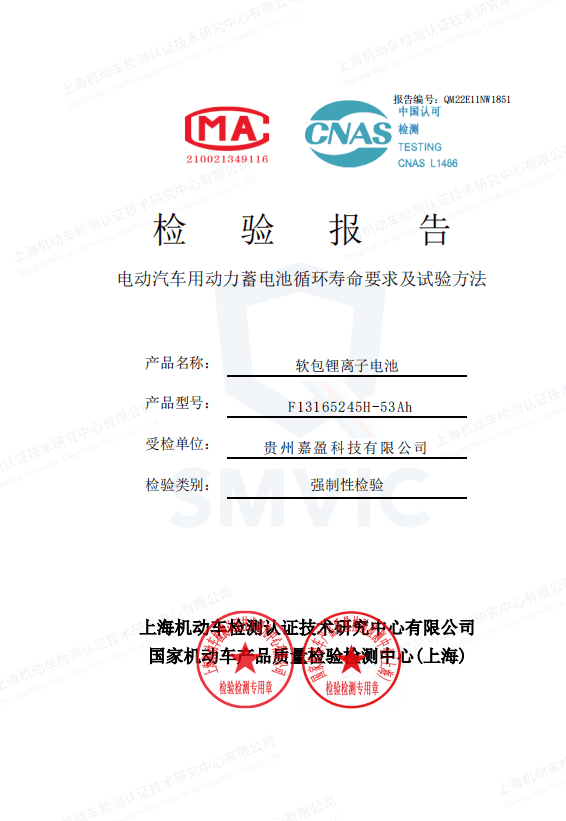

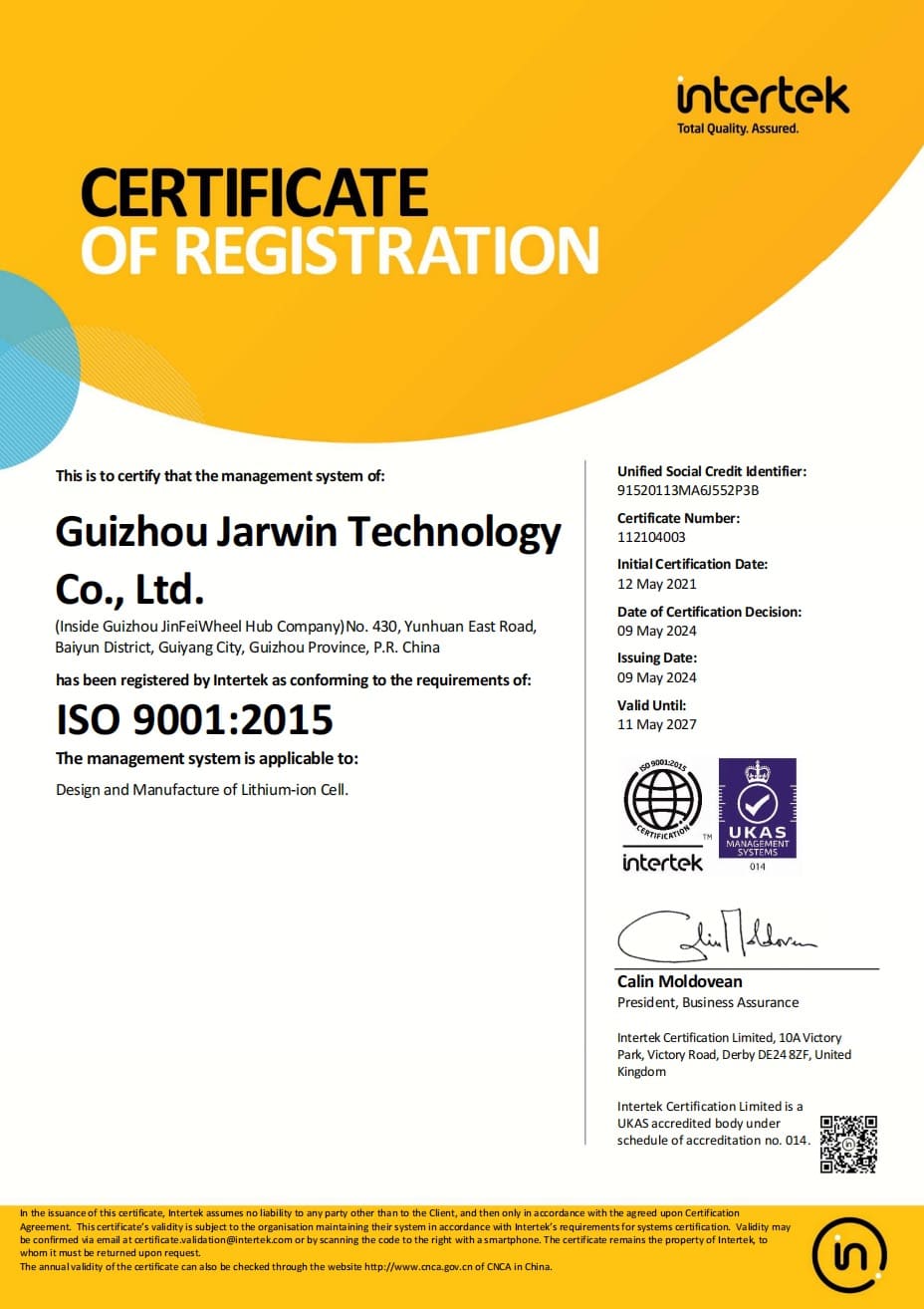

Eerlijk&Certificering

Certificeringen zijn de grootste kracht van herewin.

Voldoet aan de behoeften van alle markten en de bronfabrieken zijn volledig gecertificeerd om kwaliteit te garanderen.

IN CONTACT KOMEN

Wil je weten welke referenties jouw markt nodig heeft? Neem contact met me op en ik stuur je een afbeelding in hoge resolutie

FAQs

Li-ion polymer cells utilize gel polymer electrolyte technology, offering key differences compared to traditional liquid lithium batteries:

Electrolyte Composition

-

Hybrid gel polymer + liquid electrolyte (vs. pure liquid electrolyte in traditional cells).

Safety Improvements

-

60% lower leakage risk and 40% reduced combustion potential.

Structural Advantages

-

30% smaller volume, 20% lighter weight, and support for flexible/custom shapes.

Performance Metrics

-

Energiedichtheid: 170-350 Wh/kg

(Traditional liquid: 160-170 Wh/kg; Semi-solid energy storage series: 170-190 Wh/kg; High-density semi-solid series: 300-350 Wh/kg). -

Charging Efficiency: 50% faster than traditional batteries.

-

Levenscyclus: ≥2,000 cycles.

-

Veiligheid

-

Passes nail penetration and crush tests.

-

Stable operation at 70-80°C (158-176°F).

-

UL/CE certified.

-

-

Charging Performance

-

30-minute fast charging (up to 80% capacity).

-

Compatible with mainstream fast-charging protocols.

-

-

Sustainability

-

≥2,000-cycle lifespan.

-

95% material recyclability rate.

-

-

Compact Design

-

30% smaller size and 20% lighter weight vs. traditional cells.

-

Mainstream Applications

-

Consumer Electronics: Smartphones, TWS earbuds (prioritizing slim designs + fast charging).

-

New Energy Vehicles: Power batteries (20% range increase), flexible in-car displays.

-

Industrial Energy Storage: Residential energy storage systems (safety + longevity), backup power units.

Emerging Applications

-

IoT sensors (flexible integration), vaping devices (miniaturization), wearables.

Verwante blog

Battery selection is a mission‑critical decision for agricultural drone fleets: the wrong chemistry or inadequate sealing reduces flight duration, limits […]

Industrial mapping teams live and die by endurance, reliability, and data quality. For operators of Platform composite-wing or heavy‑lift multirotors, […]

If you operate a logistics fleet, your battery is more than a component—it affects airtime availability, operational risk, and cross-border […]

Lithium Iron Phosphate (LiFePO4) batteries have become the preferred power source for energy storage, electric vehicles, and portable devices, thanks […]

As the “power core” of drones, lithium batteries directly determine flight stability, endurance, and safety. However, issues like reduced capacity, […]

Onze nieuwe catalogus

Learn more about battery cell, and the full range of products