Lead-to-Lithium Battery

A professional solution to upgrade traditional lead-acid batteries to lithium batteries, offering smaller size, lighter weight, and superior performance. Complete retrofit solutions and technical support are provided, giving your equipment a new life with lower operational costs and higher efficiency.

Voltage: 25.6V

Size: 522*240*218mm

Capacity:100AH(2560WH)

Voltage: 12.8V

Size: 337*180*212mm

Capacity:150AH(1920WH)

Voltage: 12.8V

Size: 256*165*210mm

Capacity:100AH(1280WH)

Voltage: 25.6V

Size: 522*240*218mm

Capacity:200AH(5120WH)

Applications

Lightweight, long-life lithium batteries enhance range and reduce overall vehicle weight.

High-cycle-efficiency lithium batteries ensure continuous lighting during cloudy and rainy days.

Instant-response lithium batteries guarantee seamless power switchover for critical equipment.

Wide-temperature-range lithium batteries ensure stable operation in extreme weather conditions.

Industrial EV battery packs provide heavy-duty, reliable energy to logistics trucks, optimizing delivery efficiency and reducing carbon footprint in urban freight transport.

Cost-effective lithium batteries balance performance with affordability for rural transport needs.

FREE DESIGN

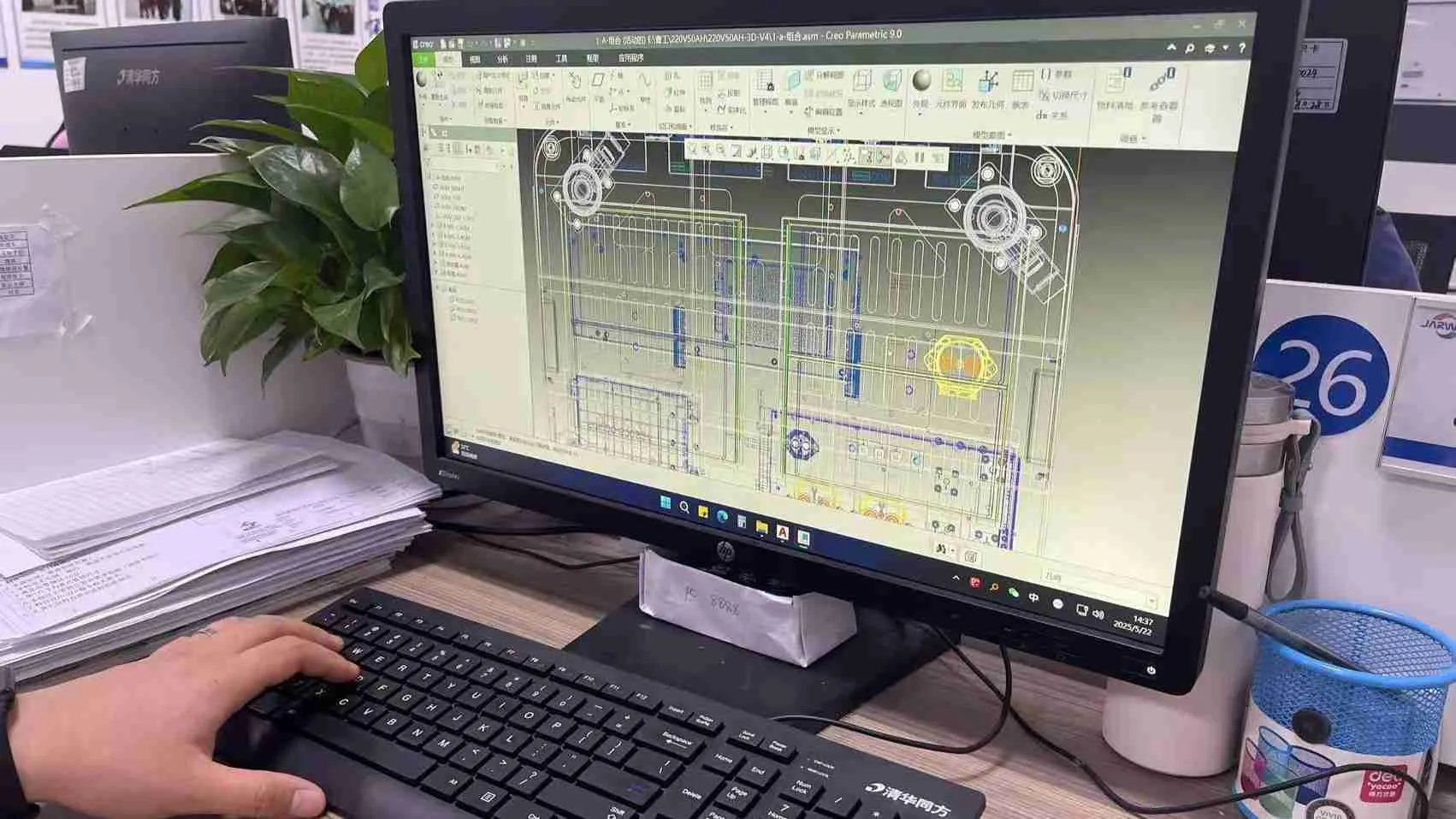

Customized exclusive battery plans! Professional engineers plan battery programs one-on-one.

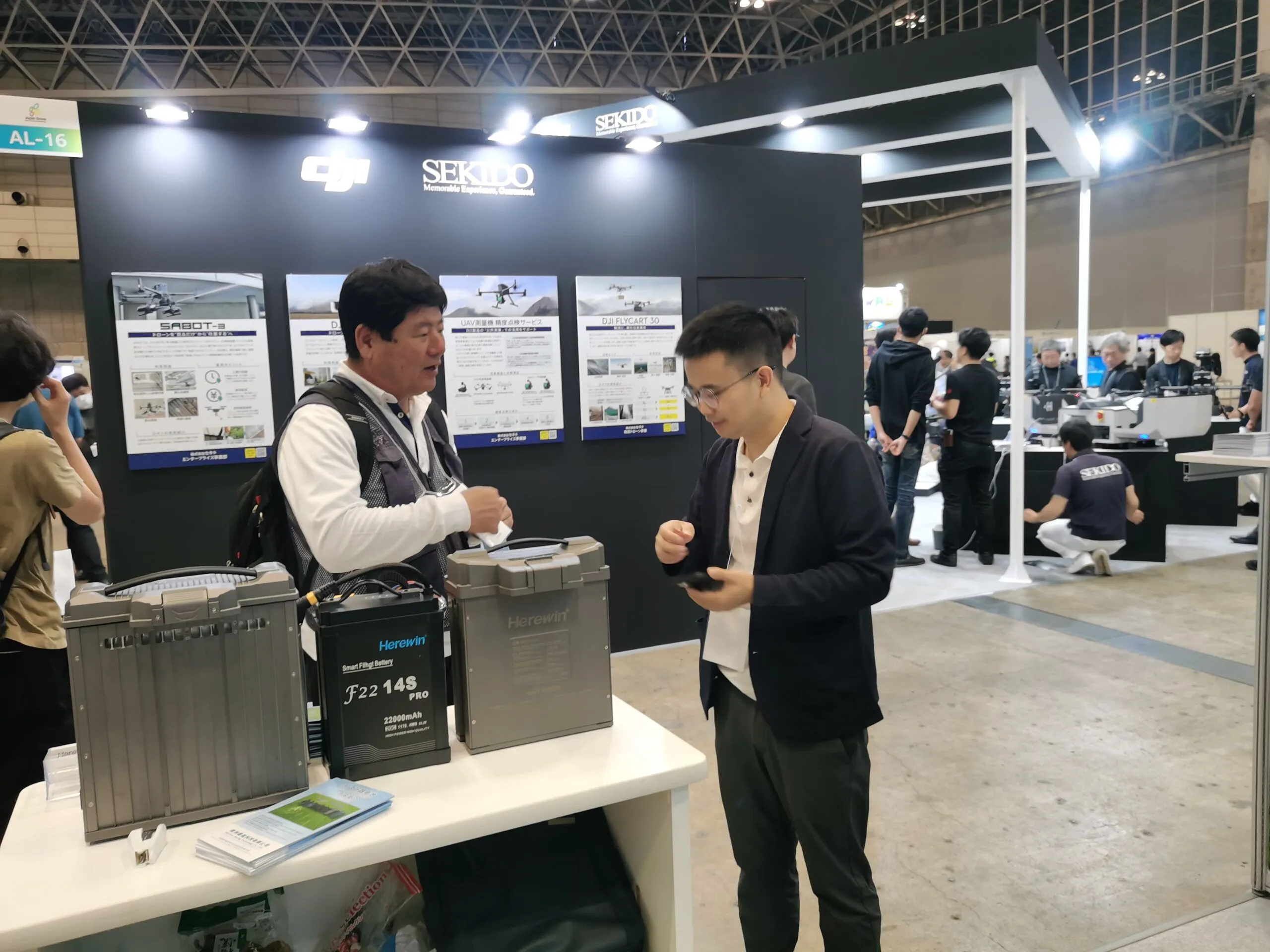

Maximize Drone Effect with Our Tailored Battery Solutions

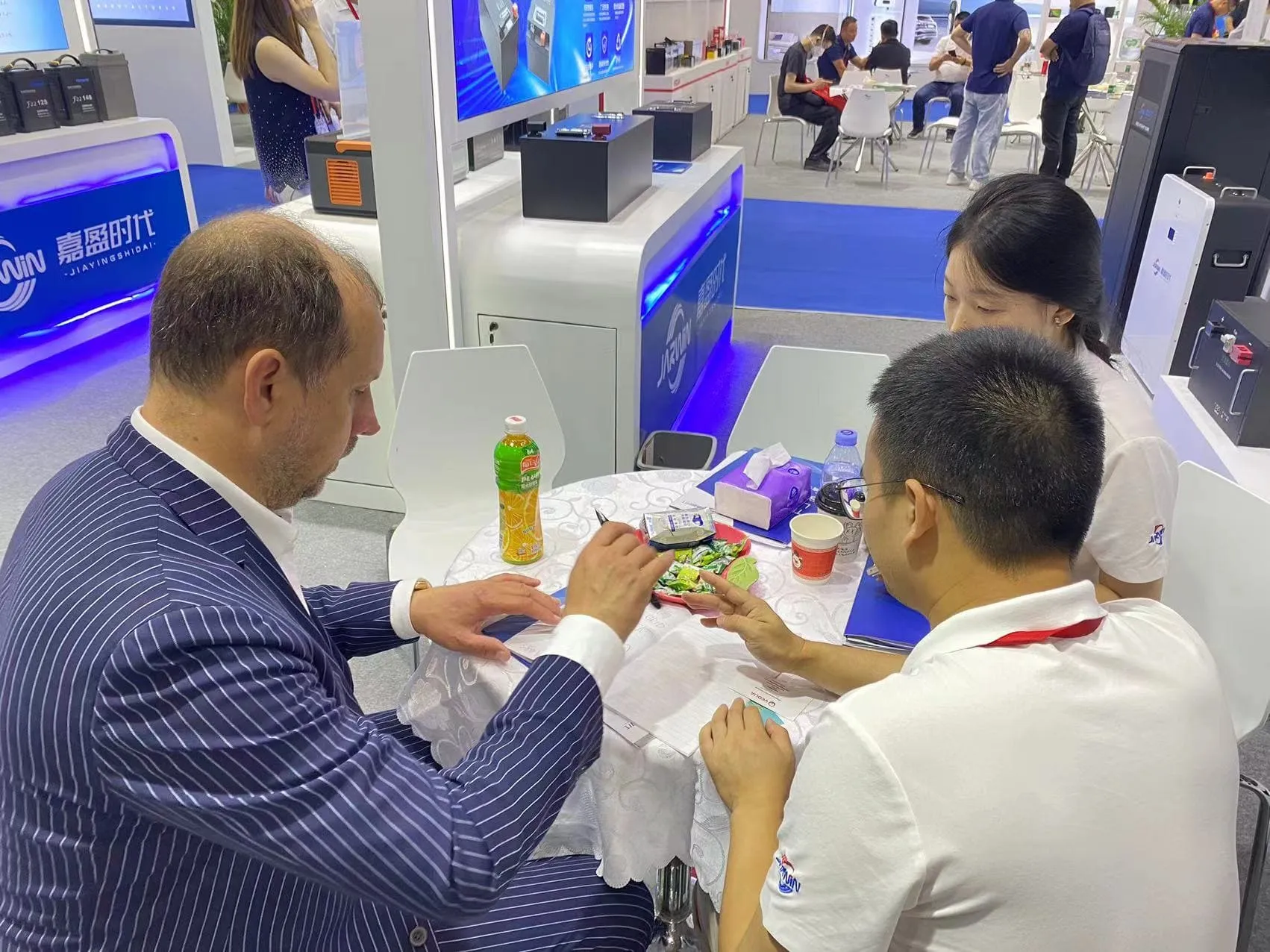

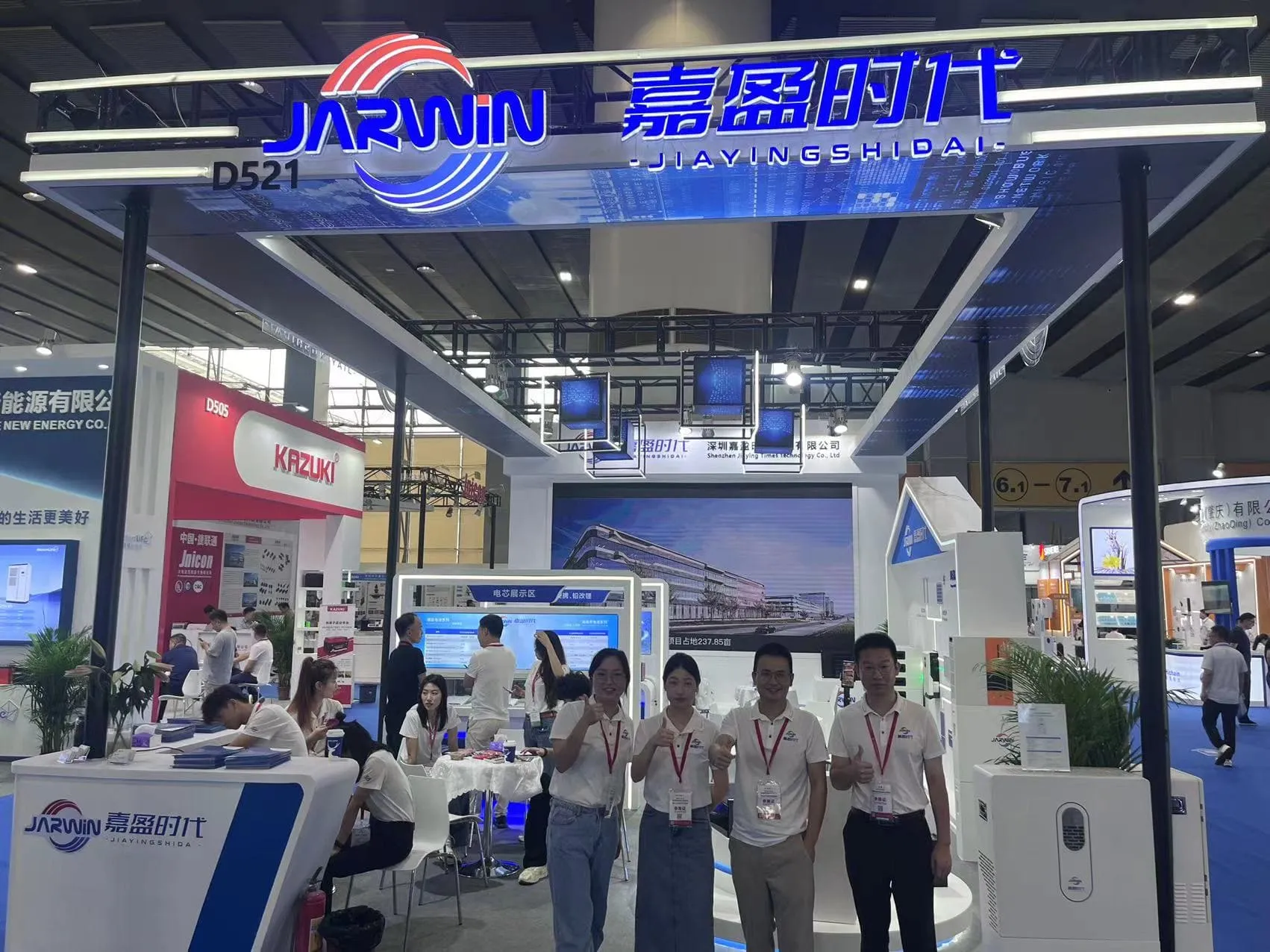

Explore Herewin Factory: The Source of Quality

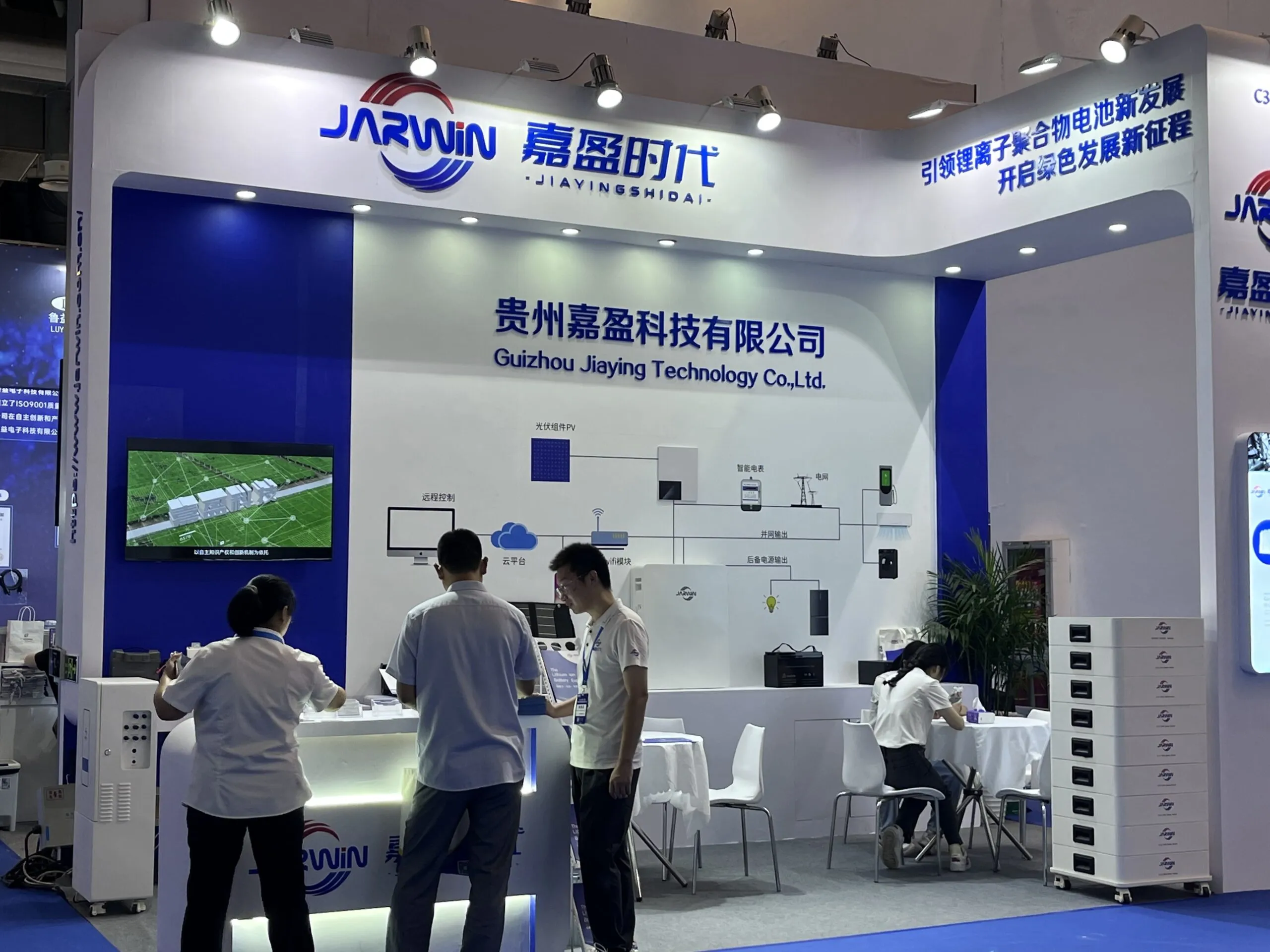

Founded in 2019, Shenzhen Jarwin Time Technology Co., Ltd. is backed by a founding and operational team with over 20 years of extensive experience in the battery industry. It specializes in developing and producing high-performance lithium-ion polymer batteries.

Gain a comprehensive insight into who we are and what we stand for. By exploring the meticulous precision of our

production lines, the efficient management of our factories, and the genuine feedback from our satisfied customers,

you’ll see how we ensure excellence at every step of the process

Different Services For Clients With Different Patterns

FOR OFFLINE CLIENTS

Flexible Delivery Time

Reliable delivery schedules and warehousing support.

High Cost-Effectiveness

Competitive pricing to maximize overall value.

Wide Product Selection

Diverse options to cater to all market segments.

FOR ONLINE CLIENTS

Low MOQ

Flexible MOQ with mixed product options.

Custom Logo

Personalized logo customization for small batches.

One-Stop Marketing Package

Provide quality images, videos to enhance sales revenue.

FOR BRAND CLIENTS

Exclusive Regional Rights

Provide all of herewin's resources and capabilities

R&D Resources

Custom sample within 7 days with R&D capabilities.

Fast Delivery

Efficient production and ship within 25 days at the fastest.

Production Flow of Industrial EV Battery

Unpack materials and sort components.

Full inspection of grouped cells for defects: leakage, scratches, dents, punctures, swelling, etc.

Load into automated equipment; add foam, test, trim, install adapter boards, and align components.

Attach foam between every two cells for protection.

Fold electrode tabs and flatten with a rubber mallet.

Weld tabs using a laser welder; clean residual slag post-welding.

Insert a pry tool sideways at weld points to detect weak bonds; rework if needed.

Wrap module with fiberboard and seal edges with fiber tape.

Secure wiring using a soldering iron.

Lay module flat, slowly slide casing over it, and fully insert into the casing.

Verify cell voltage, temperature, and voltage differentials meet standards.

Cycle batteries to stabilize performance and screen for defects.

Check communication, voltage, temperature sensing, discharge curves, and leakage.

Secure cover with screws and apply sealant evenly for waterproofing.

Inspect for scratches, adhesive residue, stripped screws, and ensure labels are intact/legible.

Repeat functional tests to confirm compliance.

Wrap finished units in PE stretch film and secure pallets with strapping.

Quality-approved units are boxed and dispatched.

LEARN MORE DETAIL

Learn more about production details and manufacturing process

Testing Process

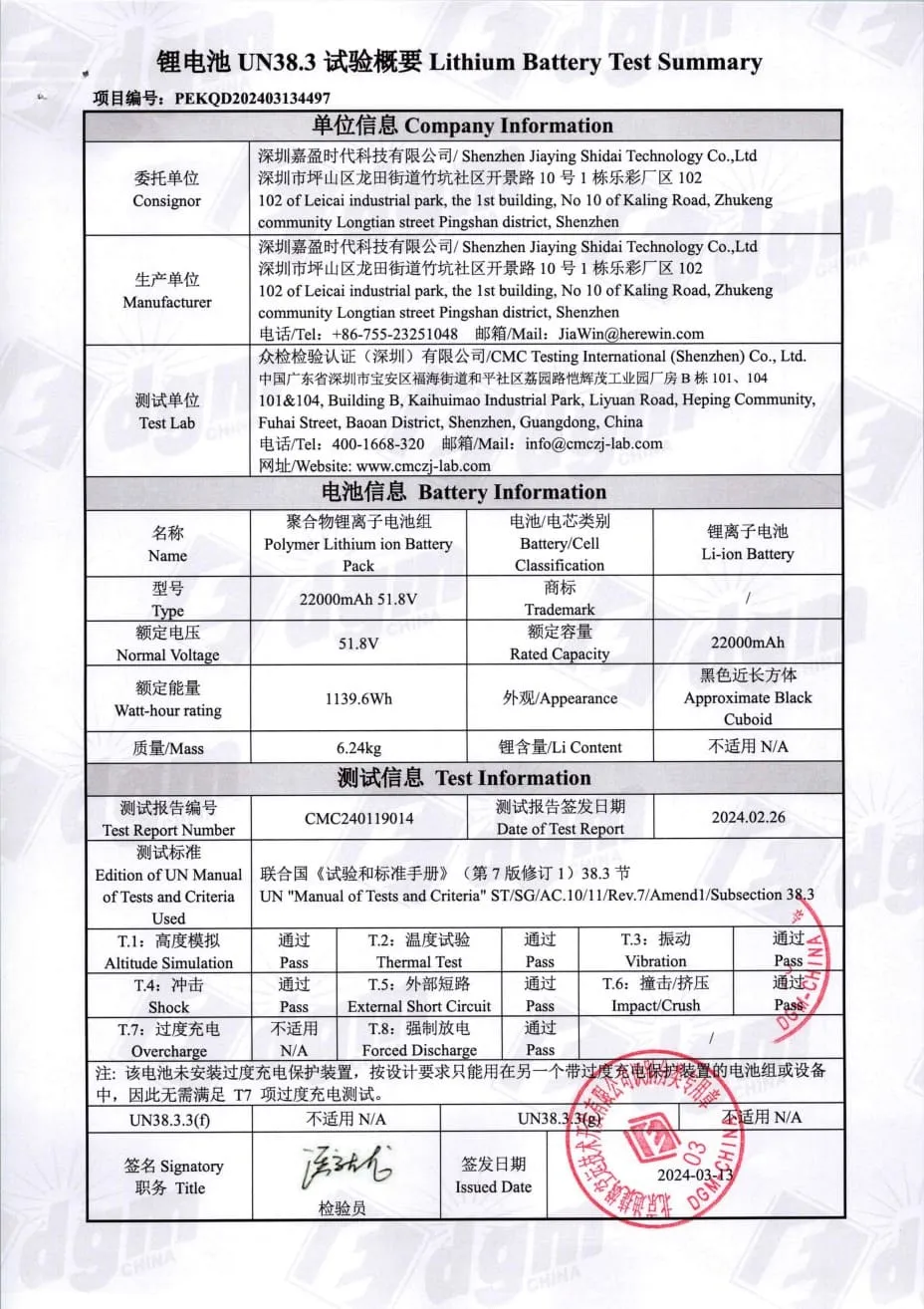

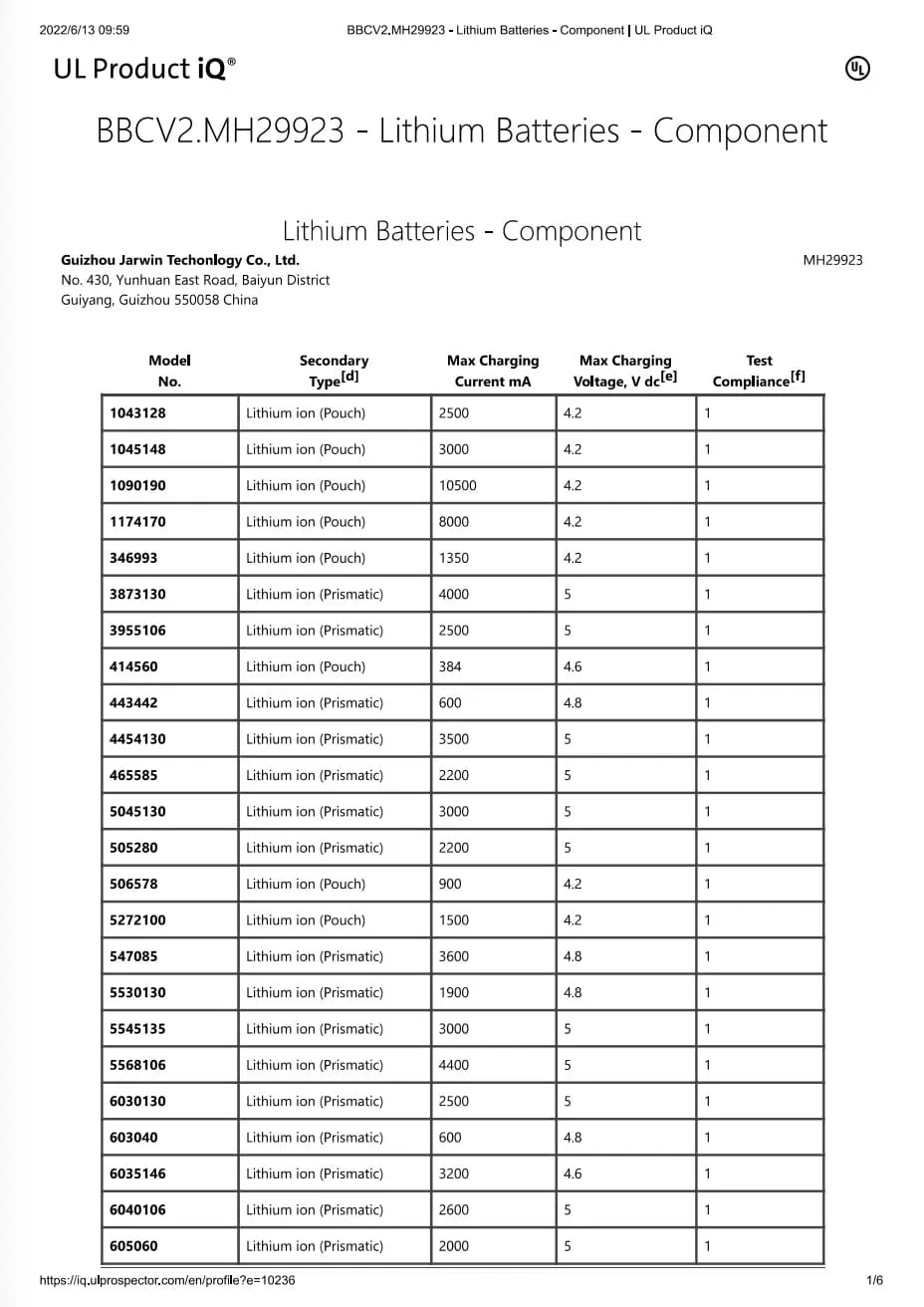

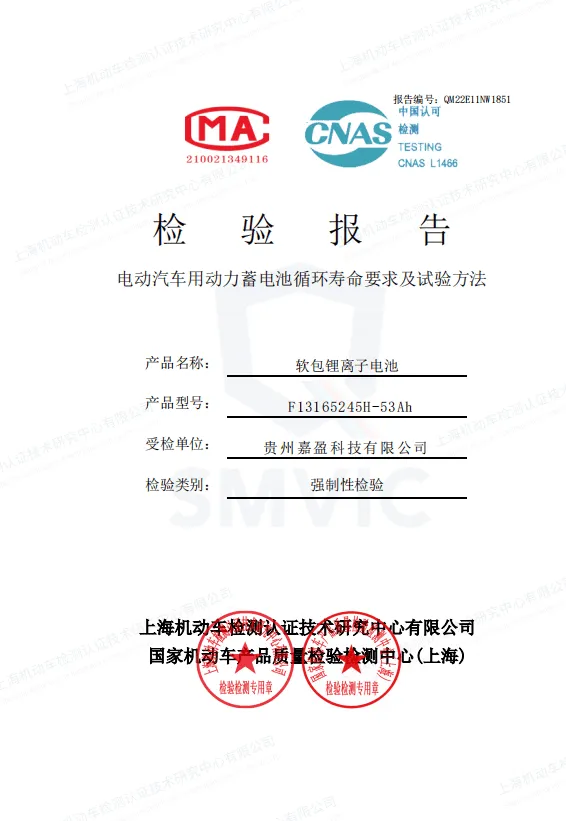

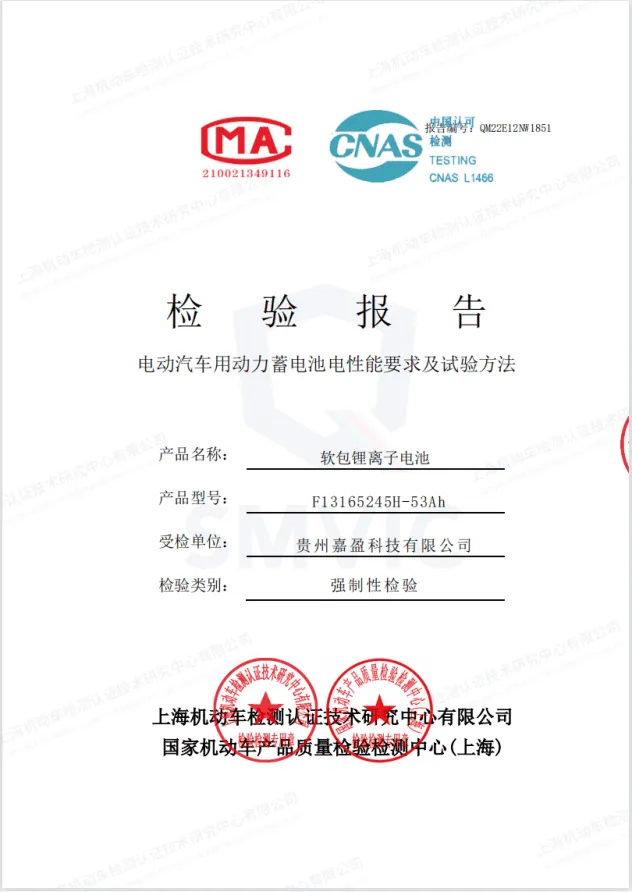

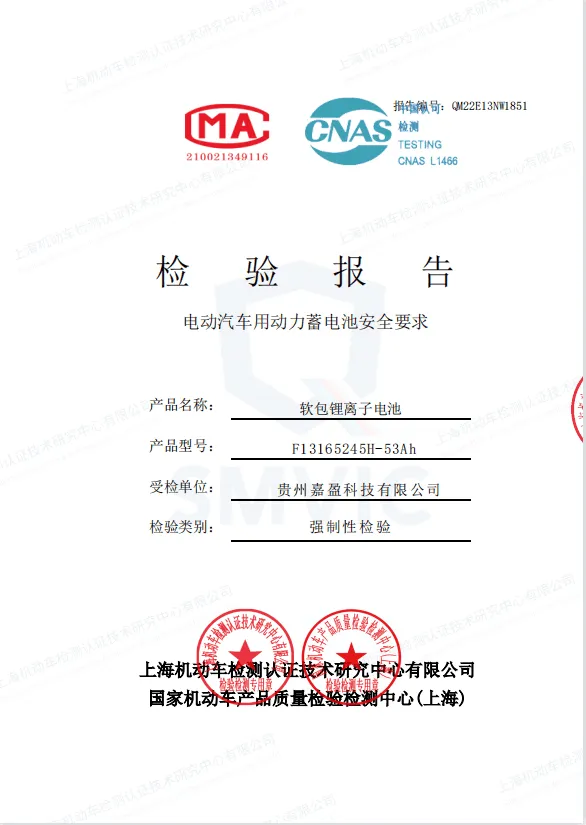

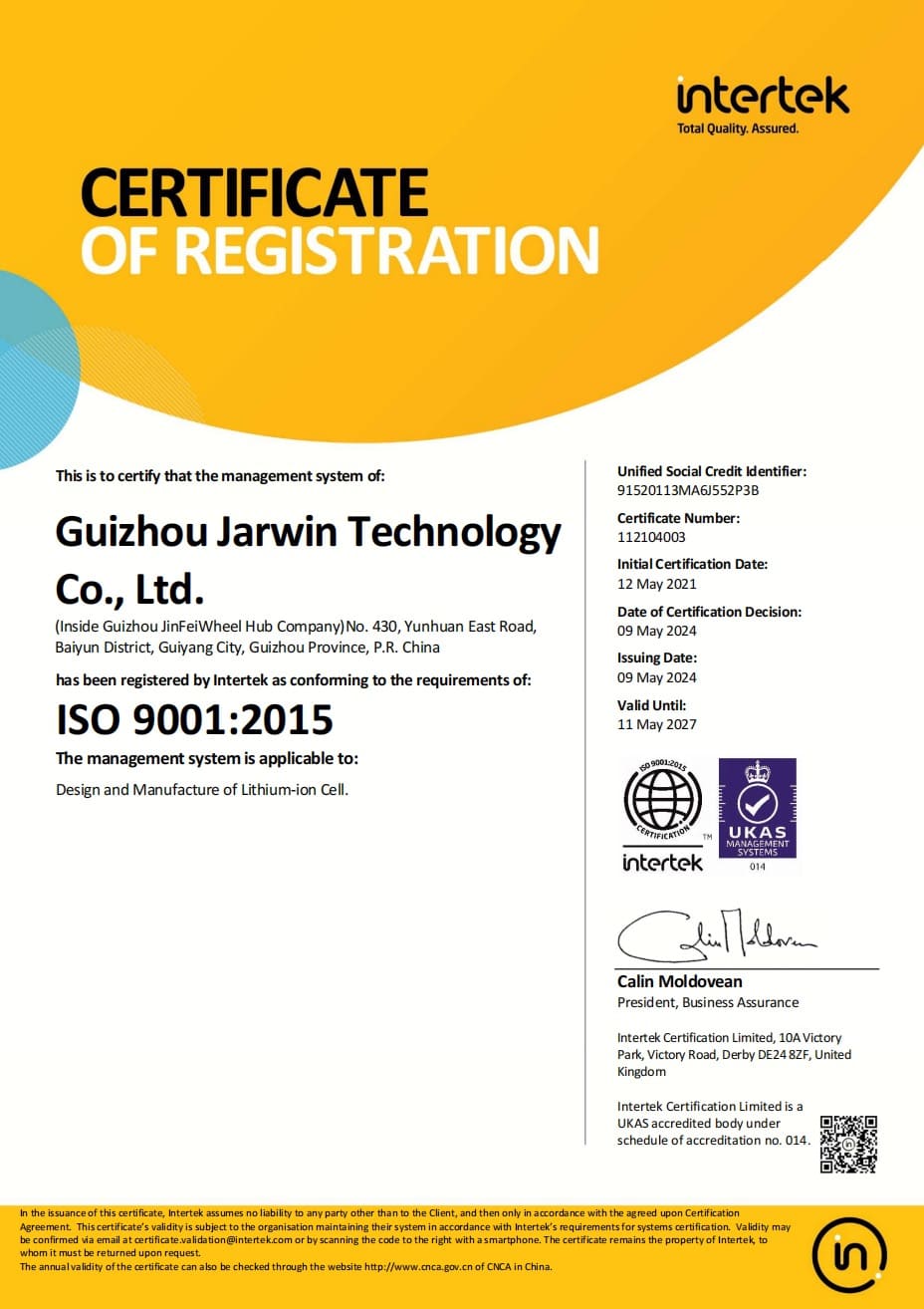

Fair&Certification

Certifications are herewin’s greatest strength.

Meets the needs of all markets, and the source factories are fully certified to ensure quality.

GET IN TOUCH

Want to know what credentials your market needs? Contact me to send you a high

FAQs

Our battery packs are designed for:

-

Logistics forklifts

-

Warehouse handling vehicles

-

Sanitation electric vehicles

-

Mining transport vehicles

Customizable voltage and capacity options are available to match specific vehicle requirements.

-

Cycle Life: ≥2,000 cycles (80% capacity retention).

-

Warranty: 3-5 years (model-dependent).

-

Features: Supports fast charging and includes remote battery health monitoring to optimize longevity.

-

Certifications: UL/CE certified.

-

Smart BMS: Built-in Battery Management System with multi-layer protection against overcharge, over-discharge, short circuits, and overheating.

-

Robust Design: Fire-resistant and shockproof construction for harsh industrial environments.

Related Blog

Battery selection is a mission‑critical decision for agricultural drone fleets: the wrong chemistry or inadequate sealing reduces flight duration, limits […]

Industrial mapping teams live and die by endurance, reliability, and data quality. For operators of Platform composite-wing or heavy‑lift multirotors, […]

If you operate a logistics fleet, your battery is more than a component—it affects airtime availability, operational risk, and cross-border […]

Lithium Iron Phosphate (LiFePO4) batteries have become the preferred power source for energy storage, electric vehicles, and portable devices, thanks […]

As the “power core” of drones, lithium batteries directly determine flight stability, endurance, and safety. However, issues like reduced capacity, […]

Our New Catalogue

Learn more about Industrial EV Battery Packs, and the full range of products