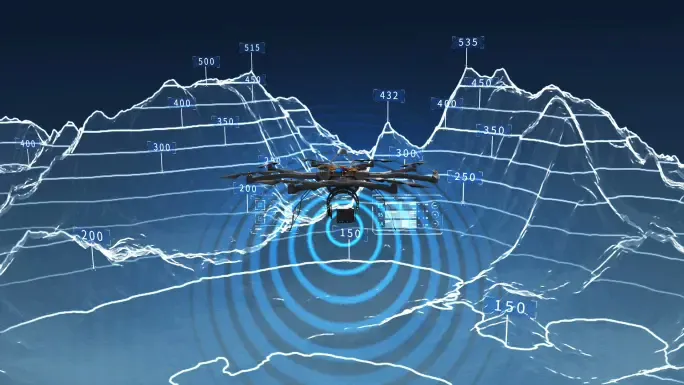

Drone Battery

HereWin Soft Pack UAV Battery utilizes aluminum-plastic film encapsulation technology, with high energy density and ultra-lightweight design as core advantages. Tailored for aerial photography, surveying, logistics, and more, it combines broad temperature adaptability and ultra-long cycle life, redefining the boundaries of drone power efficiency.

Key Highlights:

- High Efficiency & Lightweight

- Full-Scenario Temperature Adaptability

- Long Lifespan & Enhanced Safety

- Customization & Compatibility

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 6.99kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 7.3kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 6.85kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 5.8kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 4.08kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 6.1kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 650

Weight: 4.48kg

Maximum charging: 3-5C

Maximum discharge: 25C

Cycle times: ≥ 750

Weight: 10.43kg

Applications

High-density batteries enabling extended flight times and rapid recharge for seamless last-mile drone logistics.

Robust, weather-resistant batteries supporting prolonged crop spraying missions with intelligent power management.

High-voltage battery systems engineered for sustained power delivery, empowering industrial drones to effortlessly lift and transport heavy equipment.

High energy density to support frequent flights in fire scenes, high-temperature resistant packaging for complex environments, ideal for emergency takeoff, landing, and supply delivery during rescue operations.

The ultra-long cycle life battery enables drones to continuously perform large-scale terrain surveying and high-precision 3D modeling tasks in extreme temperatures.

The lightweight design enhances drone maneuverability, enabling efficient thermal imaging detection of high-voltage power grids and comprehensive inspection of complex pipeline networks.

FREE DESIGN

Customized exclusive battery plans! Professional engineers plan battery programs one-on-one.

Maximize Drone Effect with Our Tailored Battery Solutions

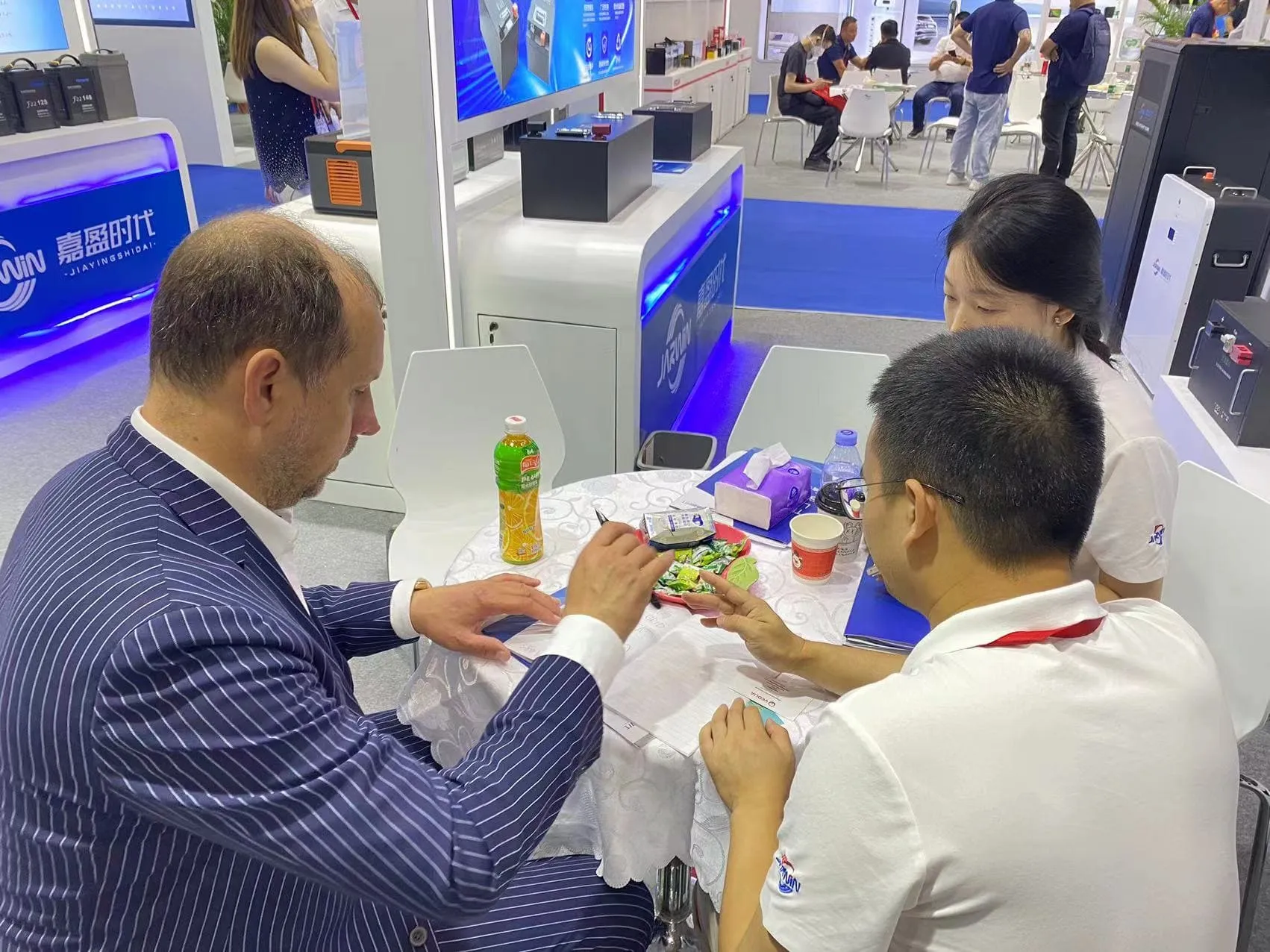

Explore Herewin Factory: The Source of Quality

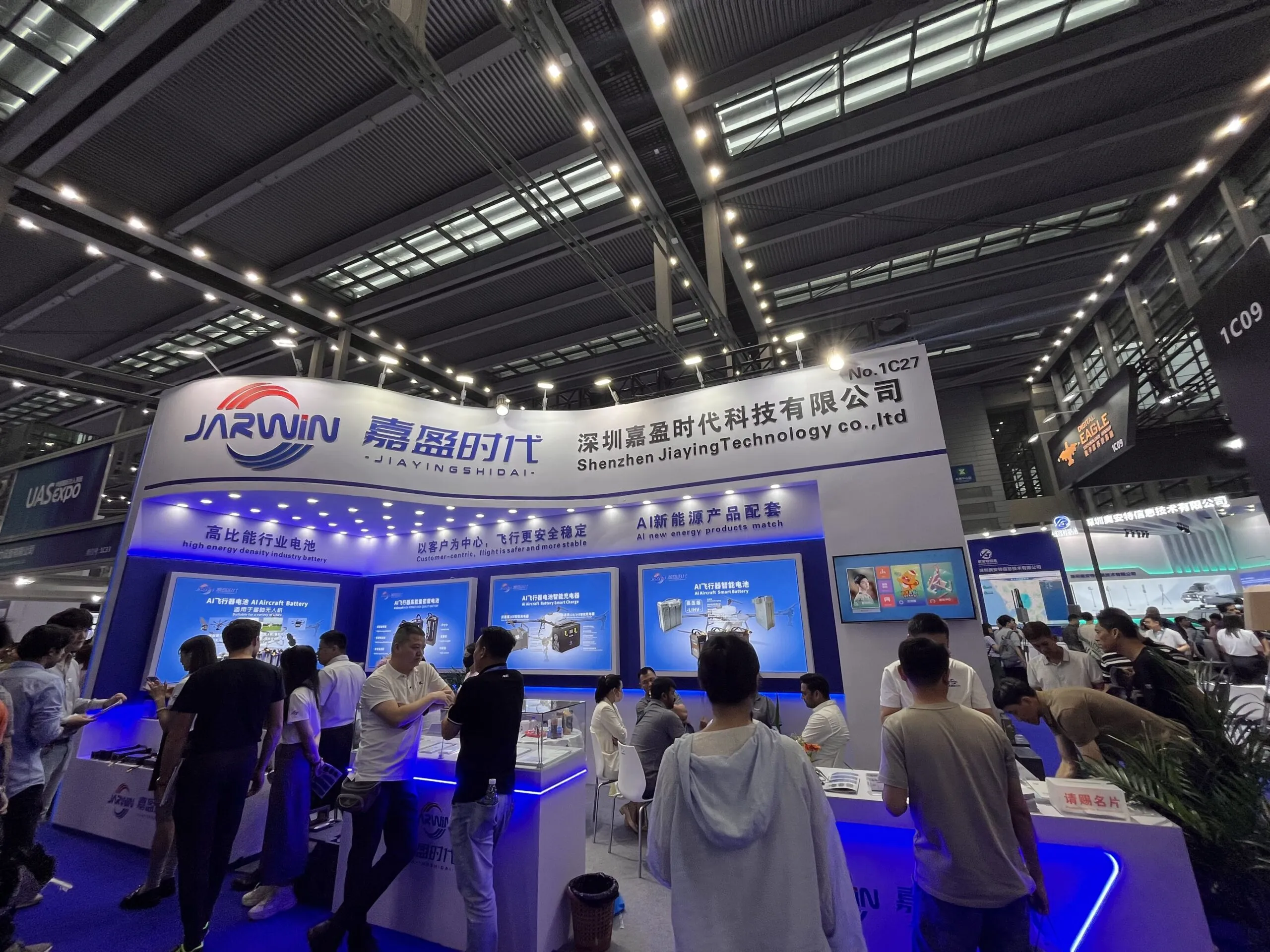

Founded in 2019, Shenzhen Jarwin Time Technology Co., Ltd. is backed by a founding and operational team with over 20 years of extensive experience in the battery industry. It specializes in developing and producing high-performance lithium-ion polymer batteries.

Gain a comprehensive insight into who we are and what we stand for. By exploring the meticulous precision of our

production lines, the efficient management of our factories, and the genuine feedback from our satisfied customers,

you’ll see how we ensure excellence at every step of the process

Different Services For Clients With Different Patterns

FOR OFFLINE CLIENTS

Flexible Delivery Time

Reliable delivery schedules and warehousing support.

High Cost-Effectiveness

Competitive pricing to maximize overall value.

Wide Product Selection

Diverse options to cater to all market segments.

FOR ONLINE CLIENTS

Low MOQ

Flexible MOQ with mixed product options.

Custom Logo

Personalized logo customization for small batches.

One-Stop Marketing Package

Provide quality images, videos to enhance sales revenue.

FOR BRAND CLIENTS

Exclusive Regional Rights

Provide all of herewin's resources and capabilities

R&D Resources

Custom sample within 7 days with R&D capabilities.

Fast Delivery

Efficient production and ship within 25 days at the fastest.

Production Flow of Drone Battery

Open packaging and sort materials.

Full inspection of grouped cells for defects: leakage, scratches, dents, punctures, swelling, improper foam alignment (exposed tabs or missing bottom foam).

Measure cell voltage and internal resistance; screen and rebalance cells with excessive deviations.

Trim electrode tabs to specification using a tab-cutting machine.

Weld tabs with an ultrasonic welder and trim to ensure flush alignment.

Trim tabs flush with weld points and press flat onto foam padding.

Solder wires using an electric iron.

Place kraft paper for insulation and cover with high-temperature adhesive tape.

Install battery module into casing per assembly specs and connect wiring.

Connect module to charger, switch to standard voltage mode, activate slow charge, and initiate charging.

Apply sealant to screw holes, install groove-down silicone plugs, and reinforce sealing at designated points.

Verify communication, output voltage, temperature sensing, discharge curves, and leakage.

Inspect for scratches, adhesive residue, stripped screws, and ensure labels are legible/undamaged.

Label units, place in foam-lined boxes, seal in PE bags with desiccant, and secure with top foam padding.

Box approved units and dispatch.

LEARN MORE DETAIL

Learn more about production details and manufacturing process

Testing Process

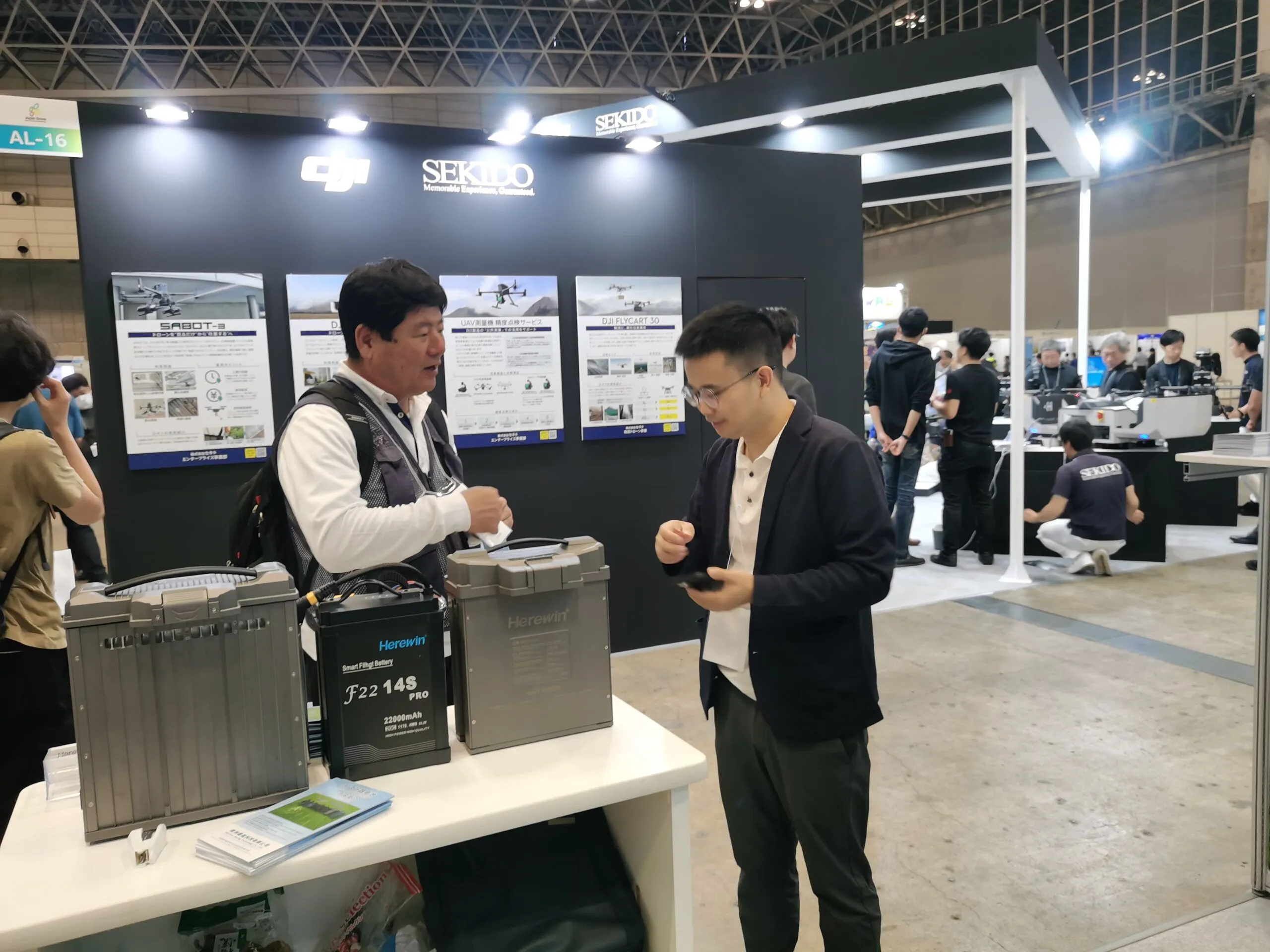

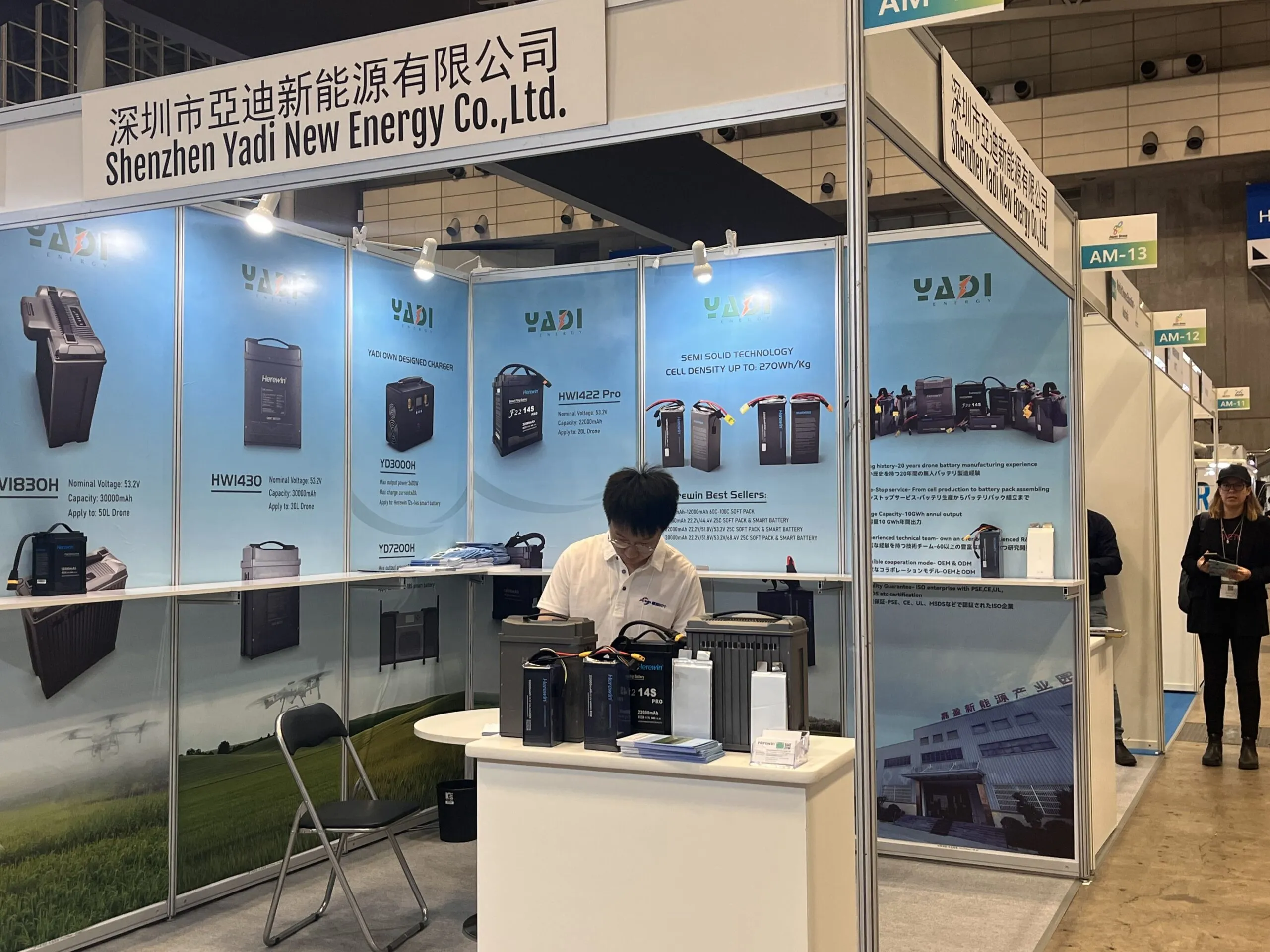

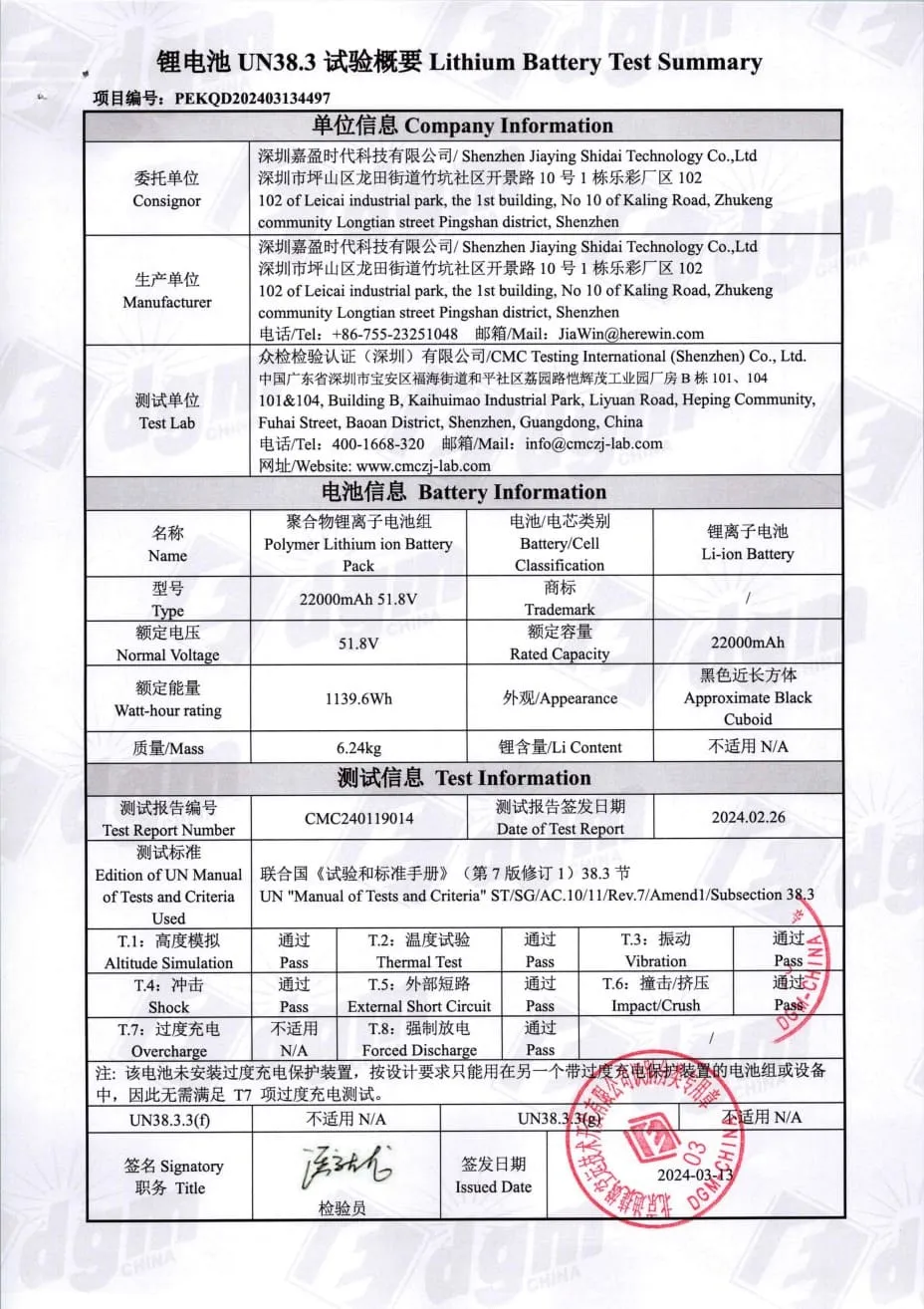

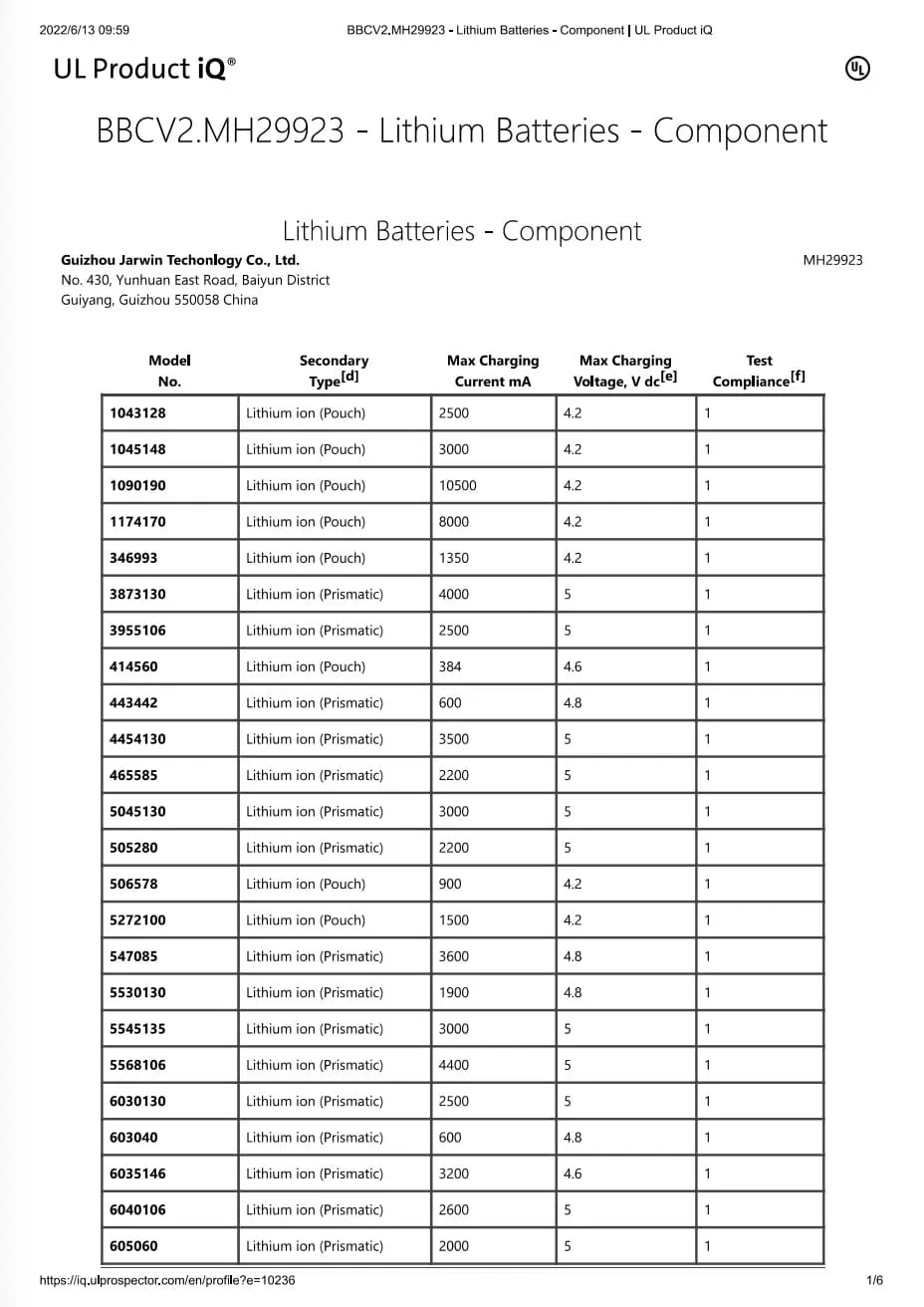

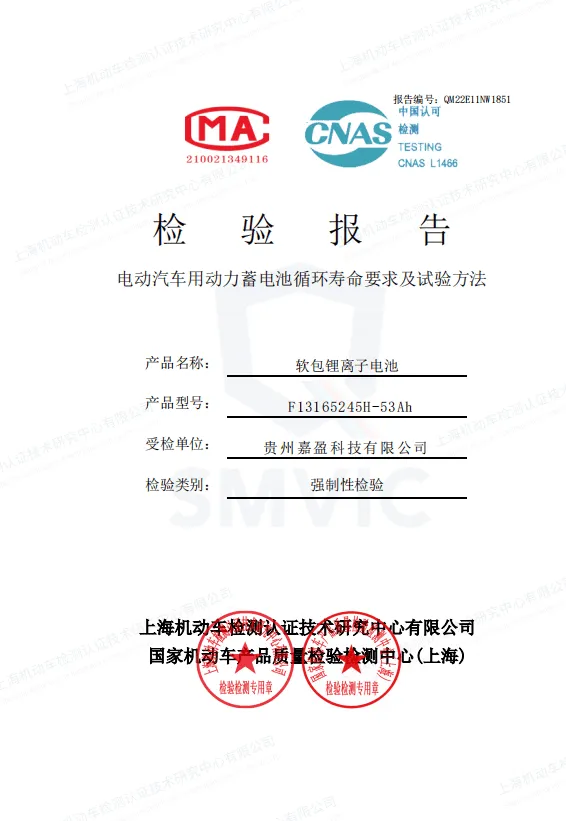

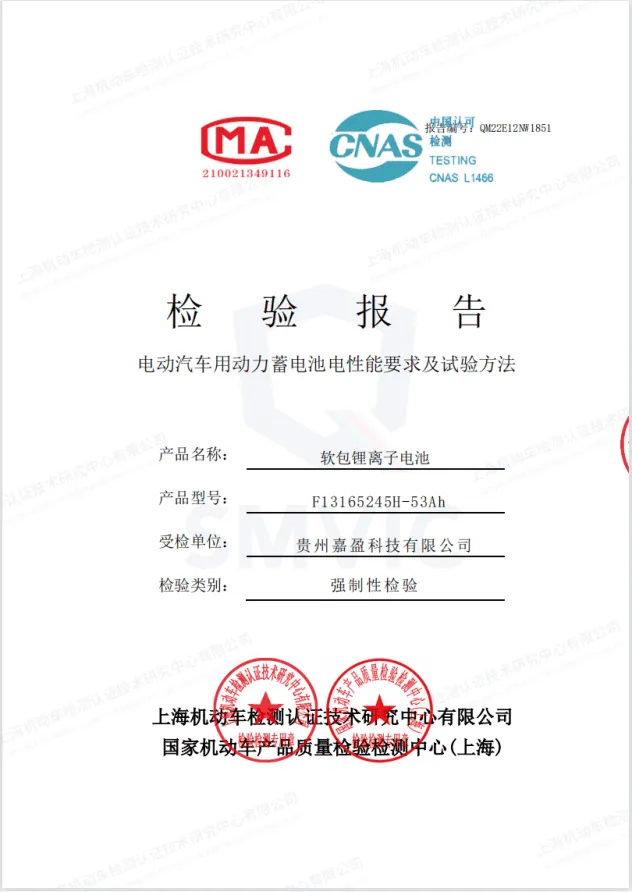

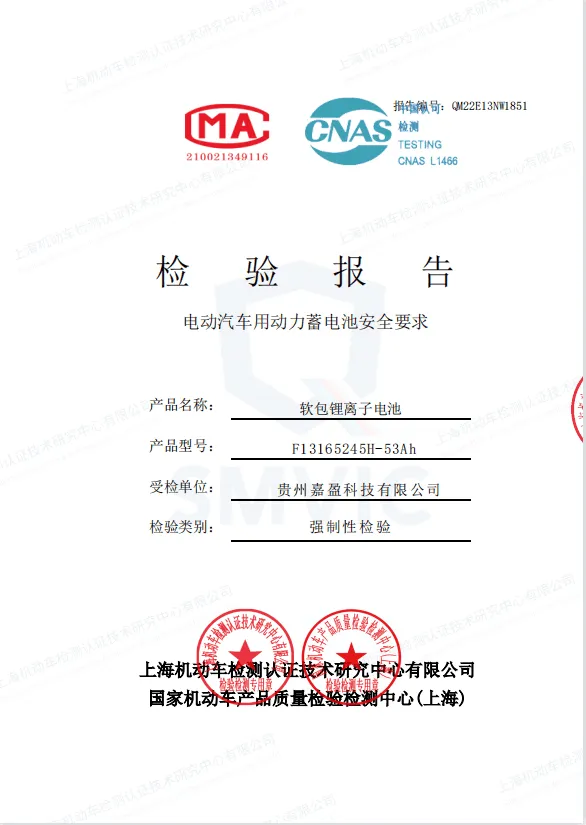

Fair&Certification

Certifications are herewin’s greatest strength.

Meets the needs of all markets, and the source factories are fully certified to ensure quality

Get In Touch With Us

Want to know what credentials your market needs? Contact me to send you a high resolution image

FAQs

Drone batteries must align with mission-specific demands:

-

Agricultural Spraying Drones: Require high-capacity batteries (8,000mAh+) for extended operation, paired with fast-charging capabilities, high-current discharge, and lightweight design.

-

Aerial Photography Drones: Prioritize compact, lightweight pouch-type polymer Li-ion batteries with extended flight time.

-

High-Speed Acrobatic Drones: Demand high discharge-rate batteries to sustain rapid acceleration bursts and stable power output.

-

Security/Mapping/Firefighting Drones: Focus on batteries with long endurance, temperature resilience, and durability across repeated cycles.

Reduced Performance in Cold Weather

-

Pre-warm batteries before use.

-

Limit flight time to half of normal duration in low temperatures.

-

Raise voltage alarm thresholds to prevent premature shutdowns.

Short Circuit Risks

-

Transport batteries in explosion-proof cases.

-

Avoid simultaneous contact of tools with positive/negative terminals during maintenance.

Casing Damage

-

Handle with care; secure straps before flight.

-

Retire batteries immediately if outer layers are compromised.

Mixing Batteries/Improper Charging

-

Never combine old and new batteries.

-

Avoid parallel charging of mismatched battery models.

Charging Protocol

-

Use manufacturer-approved chargers.

-

Prevent overcharging; perform balance charging periodically.

Storage Guidelines

-

Maintain 40-60% charge for long-term storage.

-

Store in a cool, dry environment (15-25°C / 59-77°F).

Usage Precautions

-

Avoid deep discharges (never drain below 20%).

-

Inspect for swelling, leaks, or damage post-flight.

Protective Measures

-

Keep batteries dry and shielded from corrosive substances.

-

Clean contacts and surfaces after each mission.

Related Blog

Image Source: pexels You stand in front of a shelf filled with FPV Drone Battery options, unsure which one fits […]

Get In Touch With Us

Learn more about drone batteries, and the full range of products