Batteria per carrelli elevatori

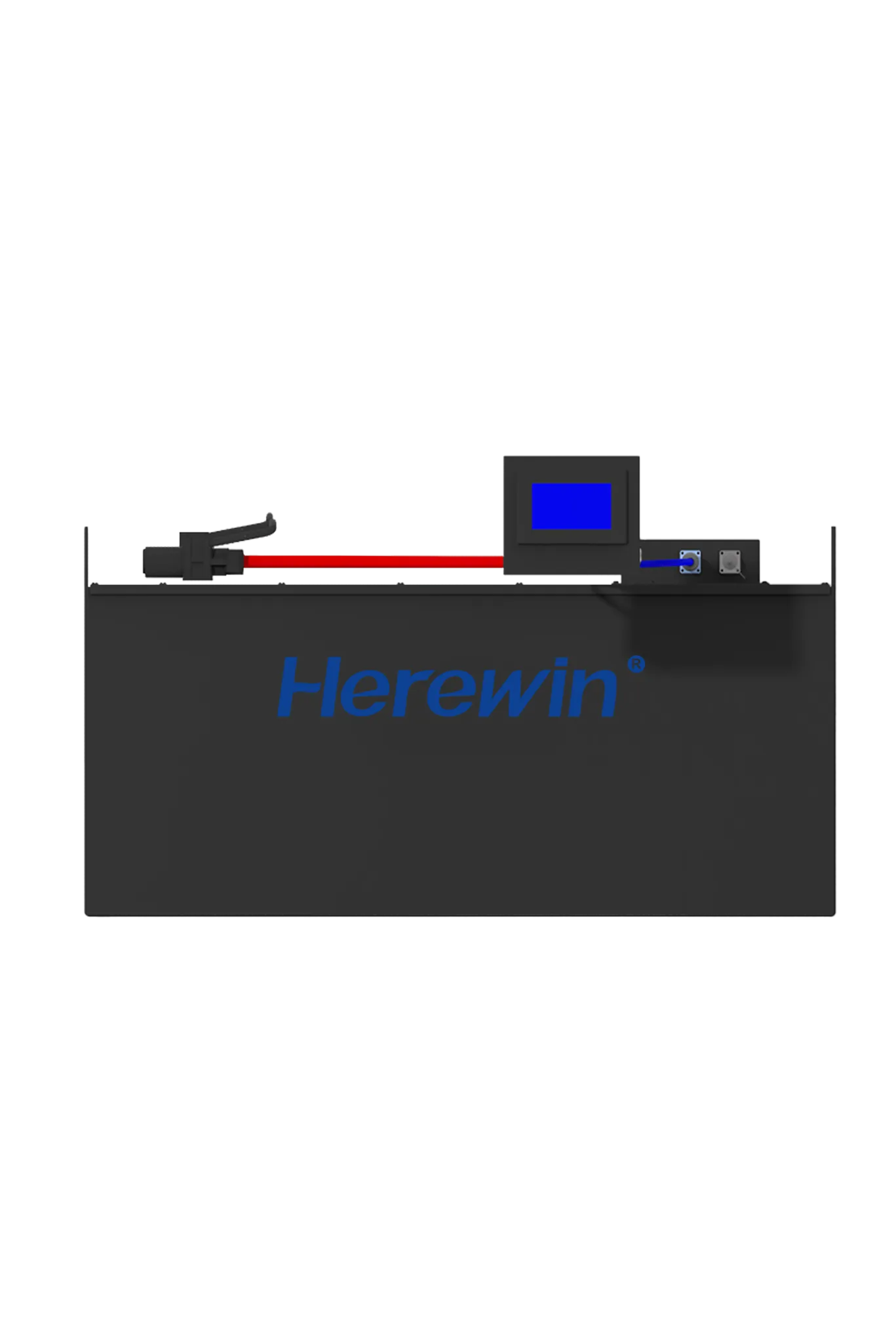

An industrial-grade power battery solution, specifically designed for electric forklifts. It uses high-discharge rate cells to meet the demands of intensive operations. The smart temperature control system ensures stable performance under various working conditions, significantly improving operational efficiency.

Nominal Capacity: 210Ah

Rated Voltage: 51.2V

Battery Energy: 10.752KWh

Battery Pack Size: 680*408*450mm

Cycle Performance: ≥3500/70% DOD

Nominal Capacity: 280Ah

Rated Voltage: 25.6V

Battery Energy: 7.168KWh

Battery Pack Size: 630*251*450mm

Cycle Performance: ≥3500/70% DOD

Nominal Capacity: 210Ah

Rated Voltage: 25.6V

Battery Energy: 5.376KWh

Battery Pack Size: 630*251*450mm

Cycle Performance: ≥3500/70% DOD

Applicazioni

Fast-charging, long-endurance batteries built for intensive, continuous operation in high-demand logistics environments.

High-power, corrosion-resistant battery systems designed for heavy cargo handling and humid coastal conditions.

Low-temperature batteries ensure reliable performance in refrigerated storage and freezing warehouse environments.

Smart battery management enables precise power monitoring and supports automatic charging for intelligent warehouse systems.

Shockproof and dust-resistant batteries engineered for harsh and rugged operating conditions.

Clean, contamination-free battery technology compliant with hygiene and safety standards for sensitive industries.

DESIGN GRATUITO

Piani di batteria esclusivi e personalizzati! Ingegneri professionisti progettano programmi di batterie uno a uno.

Massimizzate l'effetto del drone con le nostre soluzioni su misura per le batterie

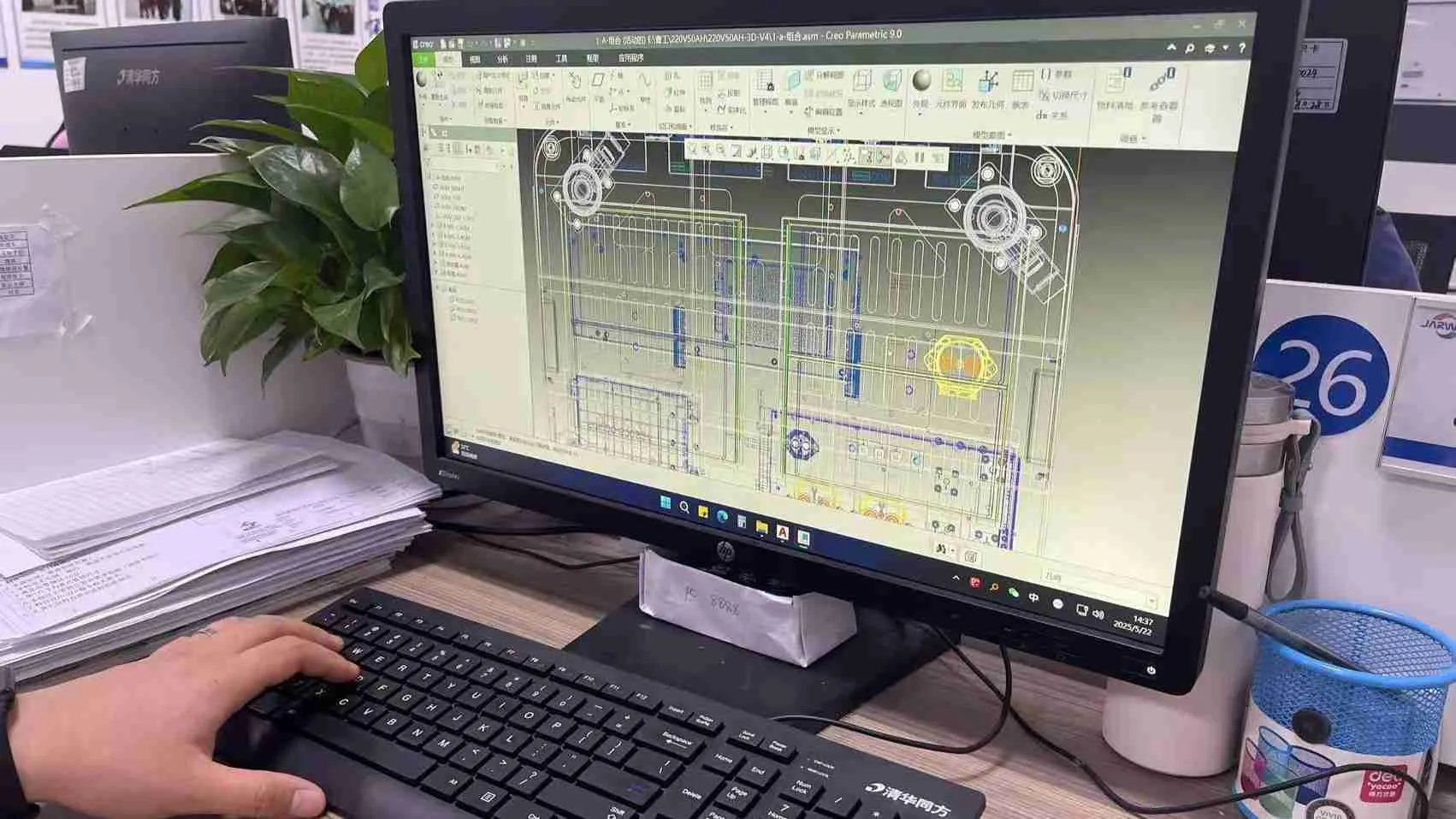

Esplora la fabbrica Herewin: La fonte della qualità

Fondata nel 2019, Shenzhen Jarwin Time Technology Co., Ltd. si avvale di un team fondatore e operativo con oltre 20 anni di vasta esperienza nel settore delle batterie. È specializzata nello sviluppo e nella produzione di batterie ai polimeri di litio ad alte prestazioni.

Scoprite chi siamo e cosa rappresentiamo. Esplorando la meticolosa precisione del nostro

linee di produzione, la gestione efficiente delle nostre fabbriche e il feedback genuino dei nostri clienti soddisfatti,

vedrete come garantiamo l'eccellenza in ogni fase del processo.

Servizi diversi per clienti con modelli diversi

PER I CLIENTI OFFLINE

Tempi di consegna flessibili

Programmi di consegna e supporto al magazzino affidabili.

Alto rapporto costo-efficacia

Prezzi competitivi per massimizzare il valore complessivo.

Ampia selezione di prodotti

Opzioni diverse per soddisfare tutti i segmenti di mercato.

PER I CLIENTI ONLINE

Basso MOQ

MOQ flessibile con opzioni di prodotti misti.

Logo personalizzato

Personalizzazione del logo per piccoli lotti.

Pacchetto Marketing One-Stop

Fornire immagini e video di qualità per migliorare le vendite.

PER I CLIENTI DEL MARCHIO

Diritti regionali esclusivi

Mettere a disposizione tutte le risorse e le capacità di herewin

R&D Resources

Custom sample within 7 days with R&D capabilities.

Consegna rapida

Produzione efficiente e spedizione entro 25 giorni al più presto.

Production Flow of Industrial EV Battery

Unpack materials and sort components.

Full inspection of grouped cells for defects: leakage, scratches, dents, punctures, swelling, etc.

Load into automated equipment; add foam, test, trim, install adapter boards, and align components.

Attach foam between every two cells for protection.

Fold electrode tabs and flatten with a rubber mallet.

Weld tabs using a laser welder; clean residual slag post-welding.

Insert a pry tool sideways at weld points to detect weak bonds; rework if needed.

Wrap module with fiberboard and seal edges with fiber tape.

Secure wiring using a soldering iron.

Lay module flat, slowly slide casing over it, and fully insert into the casing.

Verify cell voltage, temperature, and voltage differentials meet standards.

Cycle batteries to stabilize performance and screen for defects.

Check communication, voltage, temperature sensing, discharge curves, and leakage.

Secure cover with screws and apply sealant evenly for waterproofing.

Inspect for scratches, adhesive residue, stripped screws, and ensure labels are intact/legible.

Repeat functional tests to confirm compliance.

Wrap finished units in PE stretch film and secure pallets with strapping.

Quality-approved units are boxed and dispatched.

PER SAPERNE DI PIÙ

Per saperne di più sui dettagli di produzione e sul processo di fabbricazione

Processo di test

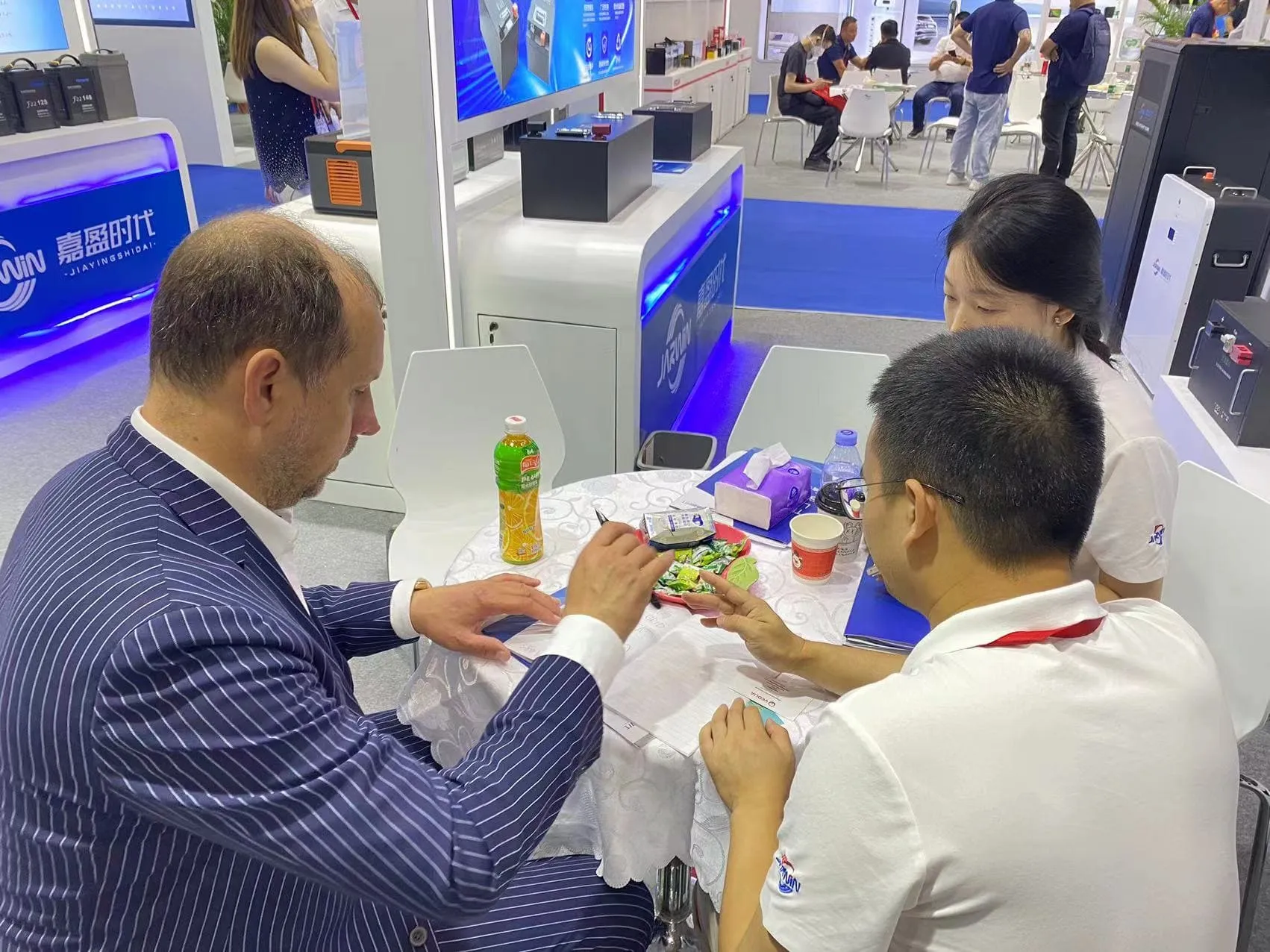

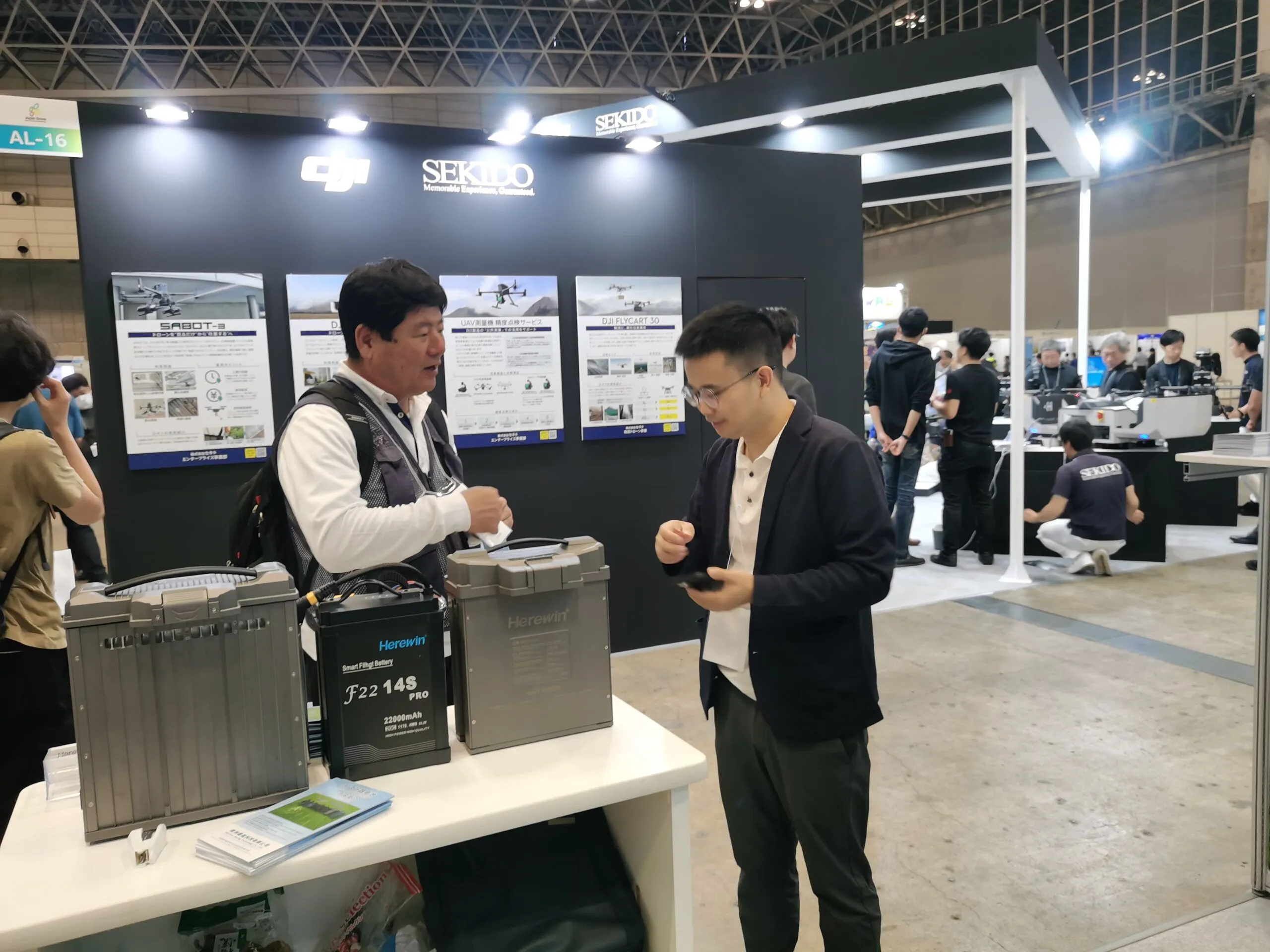

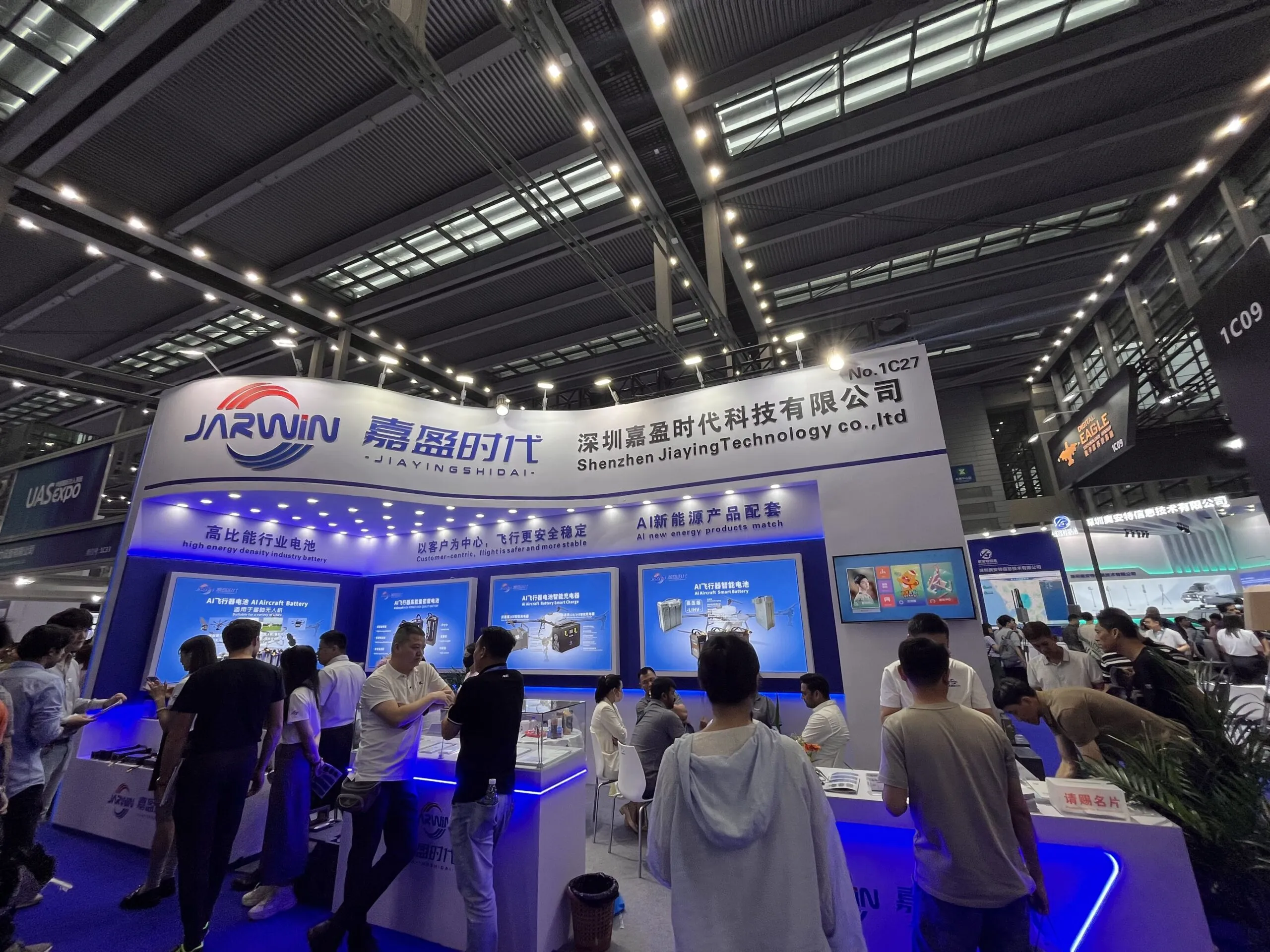

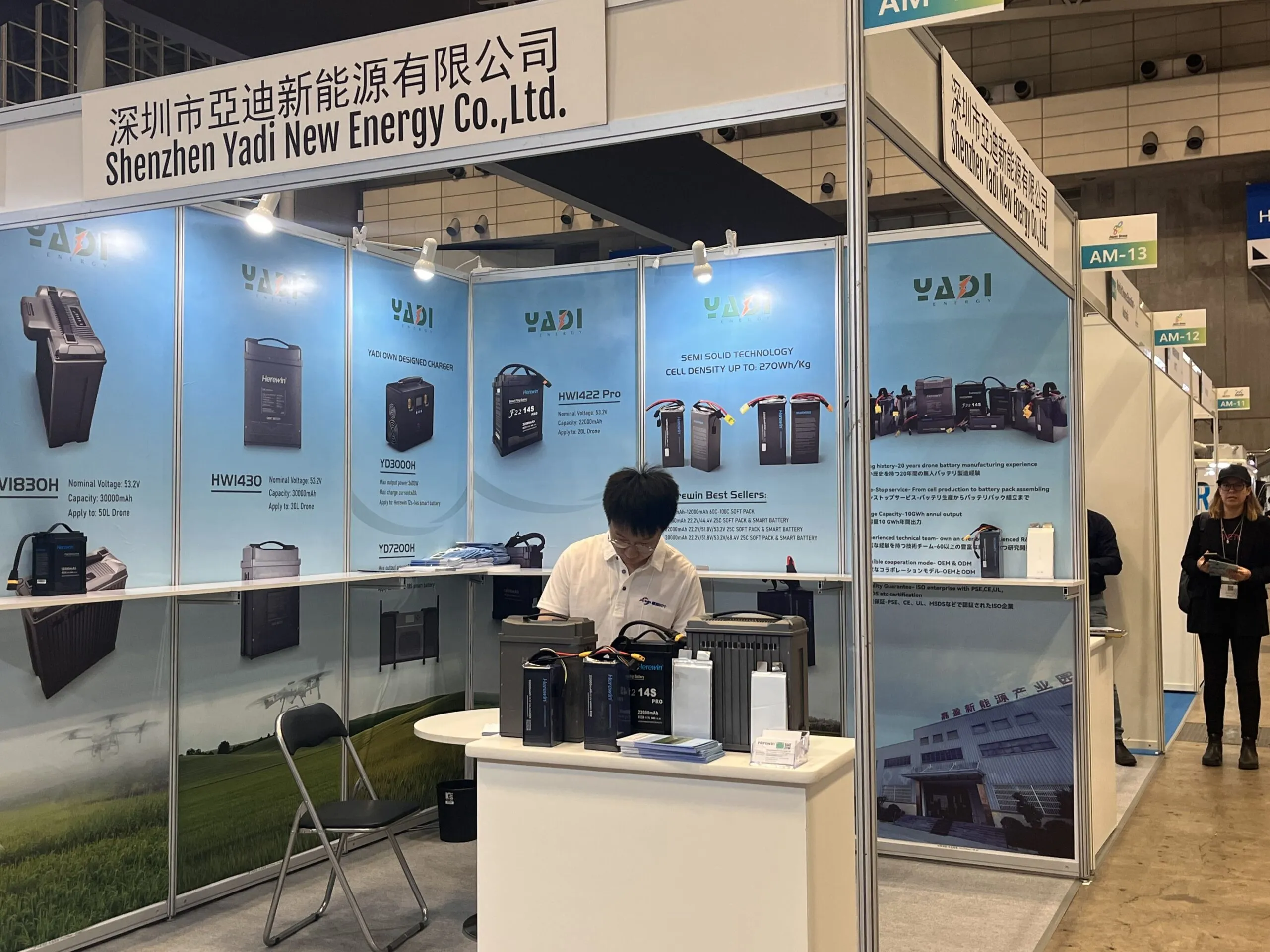

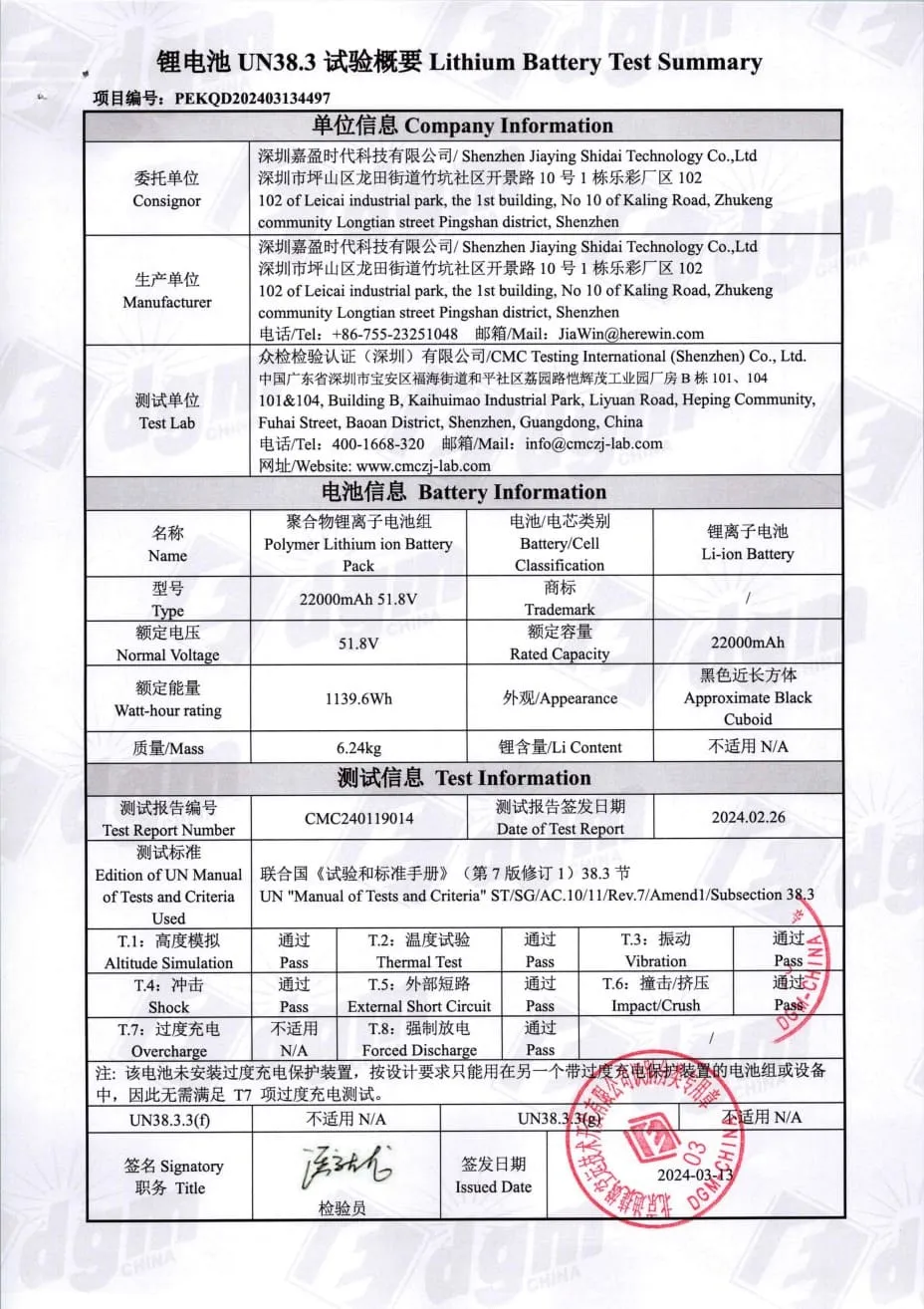

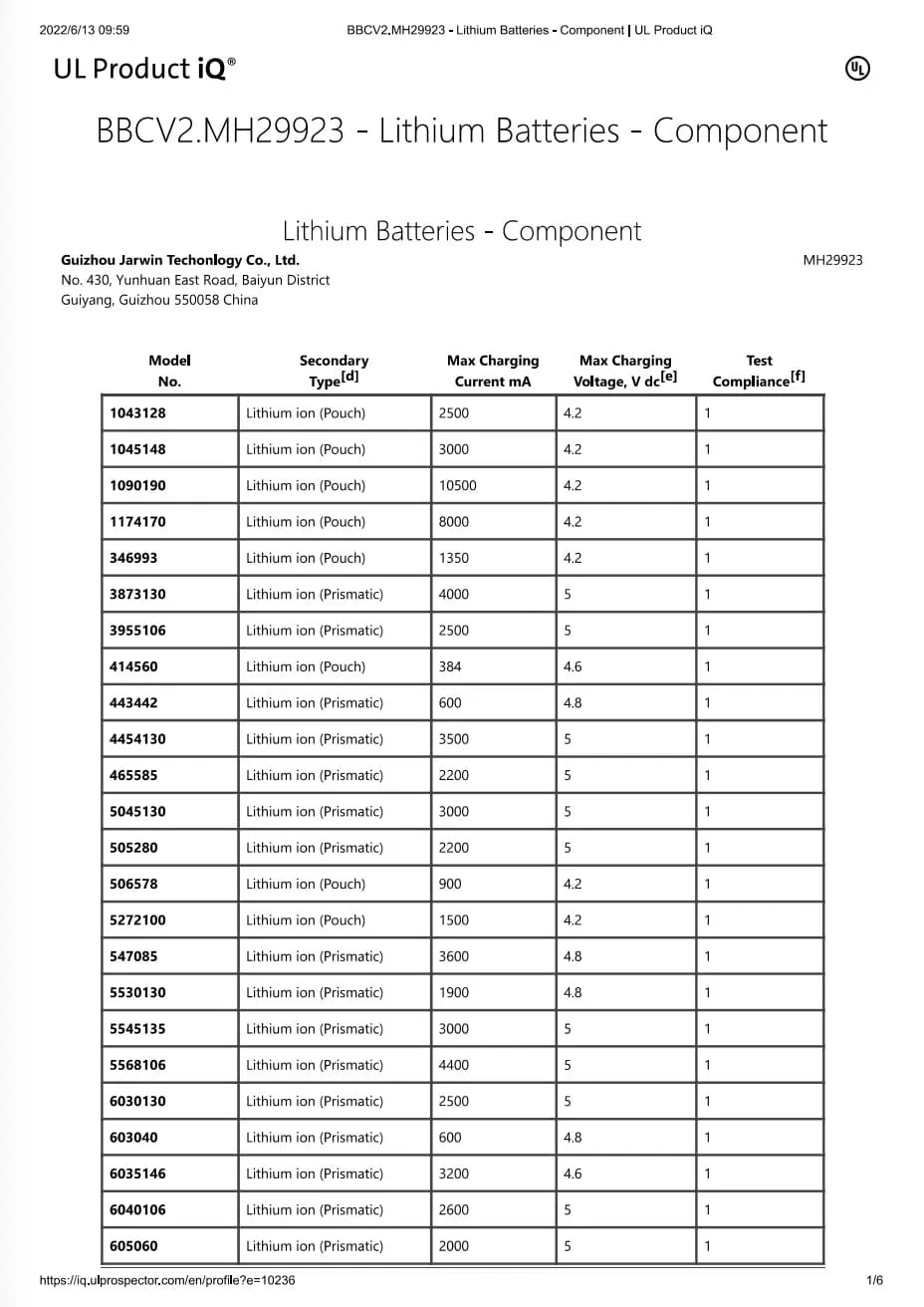

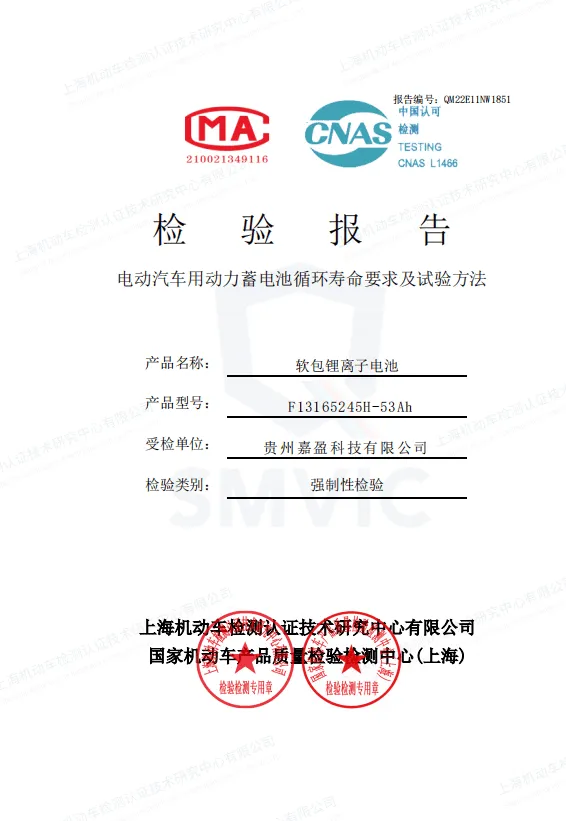

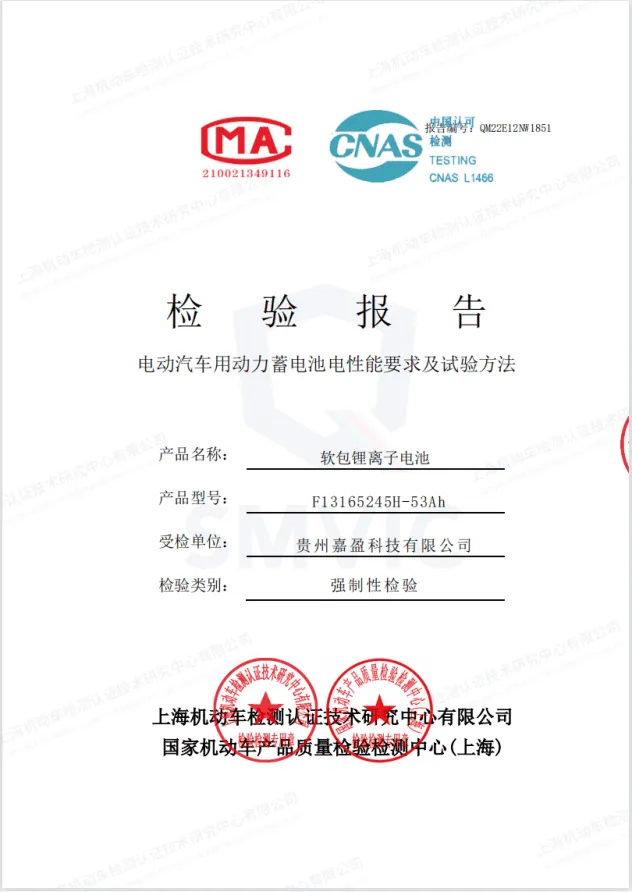

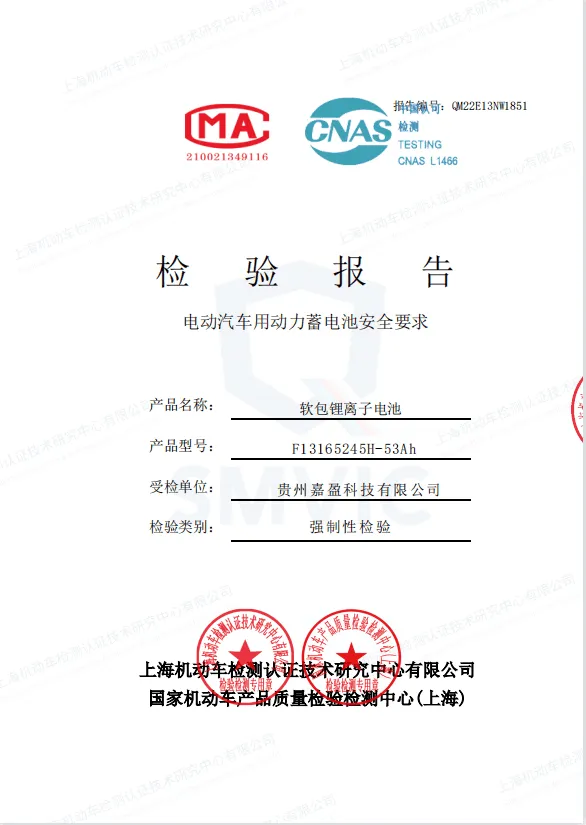

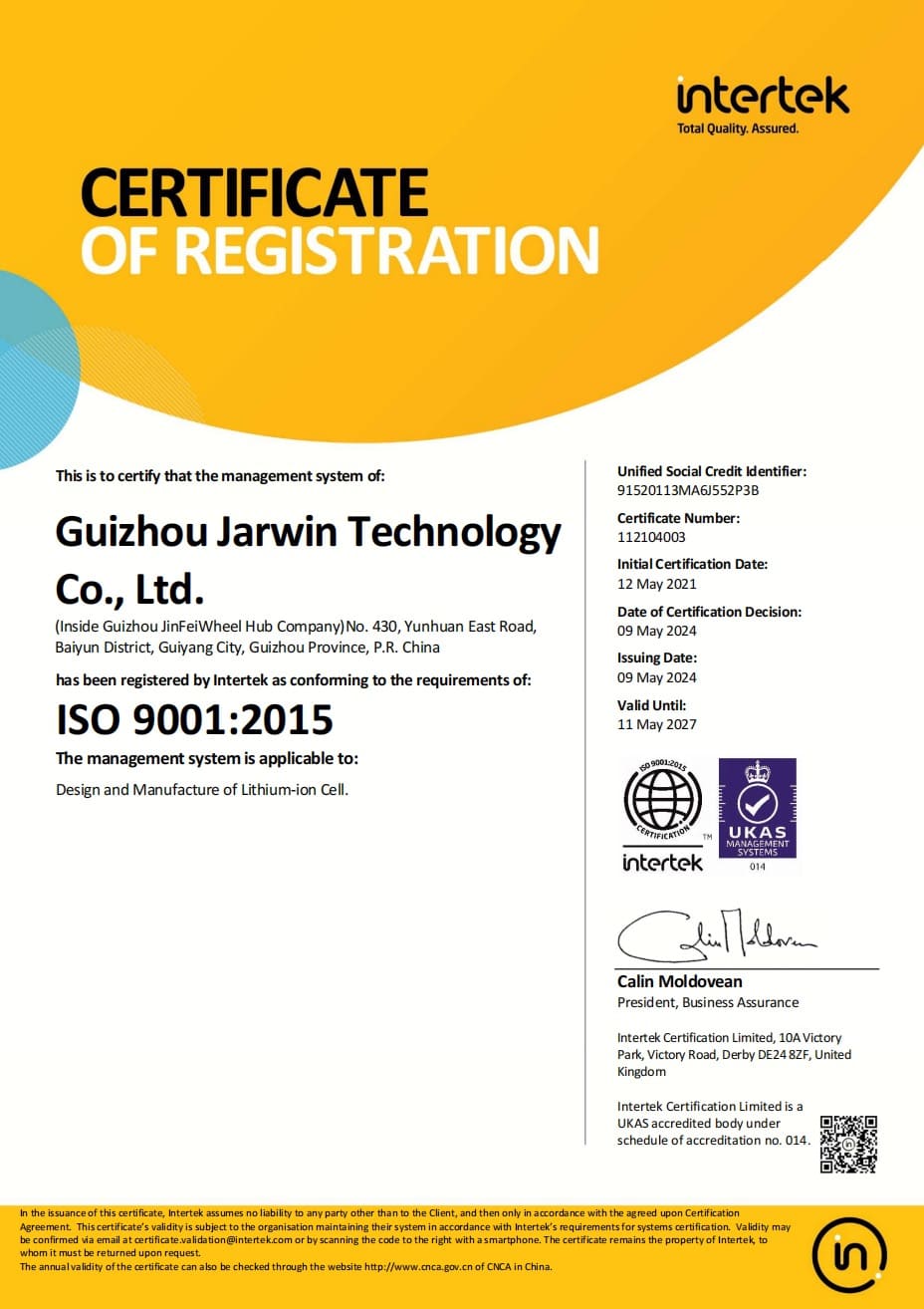

Fiera&Certificazione

Le certificazioni sono il maggior punto di forza di herewin.

Soddisfa le esigenze di tutti i mercati e le fabbriche di provenienza sono completamente certificate per garantire la qualità.

CONTATTATECI

Want to know what credentials your market needs? Contact me to send you a high

Domande frequenti

Our battery packs are designed for:

-

Logistics forklifts

-

Warehouse handling vehicles

-

Sanitation electric vehicles

-

Mining transport vehicles

Customizable voltage and capacity options are available to match specific vehicle requirements.

-

Ciclo di vita: ≥2,000 cycles (80% capacity retention).

-

Warranty: 3-5 years (model-dependent).

-

Features: Supports fast charging and includes remote battery health monitoring to optimize longevity.

-

Certifications: UL/CE certified.

-

Smart BMS: Built-in Battery Management System with multi-layer protection against overcharge, over-discharge, short circuits, and overheating.

-

Robust Design: Fire-resistant and shockproof construction for harsh industrial environments.

Blog correlati

Battery selection is a mission‑critical decision for agricultural drone fleets: the wrong chemistry or inadequate sealing reduces flight duration, limits […]

Industrial mapping teams live and die by endurance, reliability, and data quality. For operators of Platform composite-wing or heavy‑lift multirotors, […]

If you operate a logistics fleet, your battery is more than a component—it affects airtime availability, operational risk, and cross-border […]

Lithium Iron Phosphate (LiFePO4) batteries have become the preferred power source for energy storage, electric vehicles, and portable devices, thanks […]

As the “power core” of drones, lithium batteries directly determine flight stability, endurance, and safety. However, issues like reduced capacity, […]

Il nostro nuovo catalogo

Learn more about Industrial EV Battery Packs, and the full range of products