Pilas de batería

Battery cell is the smallest energy unit of the battery system, realizing the storage and release of electric energy through electrochemical reactions. Its performance directly determines the energy density, life and safety of the battery module and system, which can be categorized into lithium ternary (NCM/NCA), lithium iron phosphate (LFP), lithium cobalt oxide (LCO), Lithium manganese iron phosphate(LTO) and other types according to the material system.

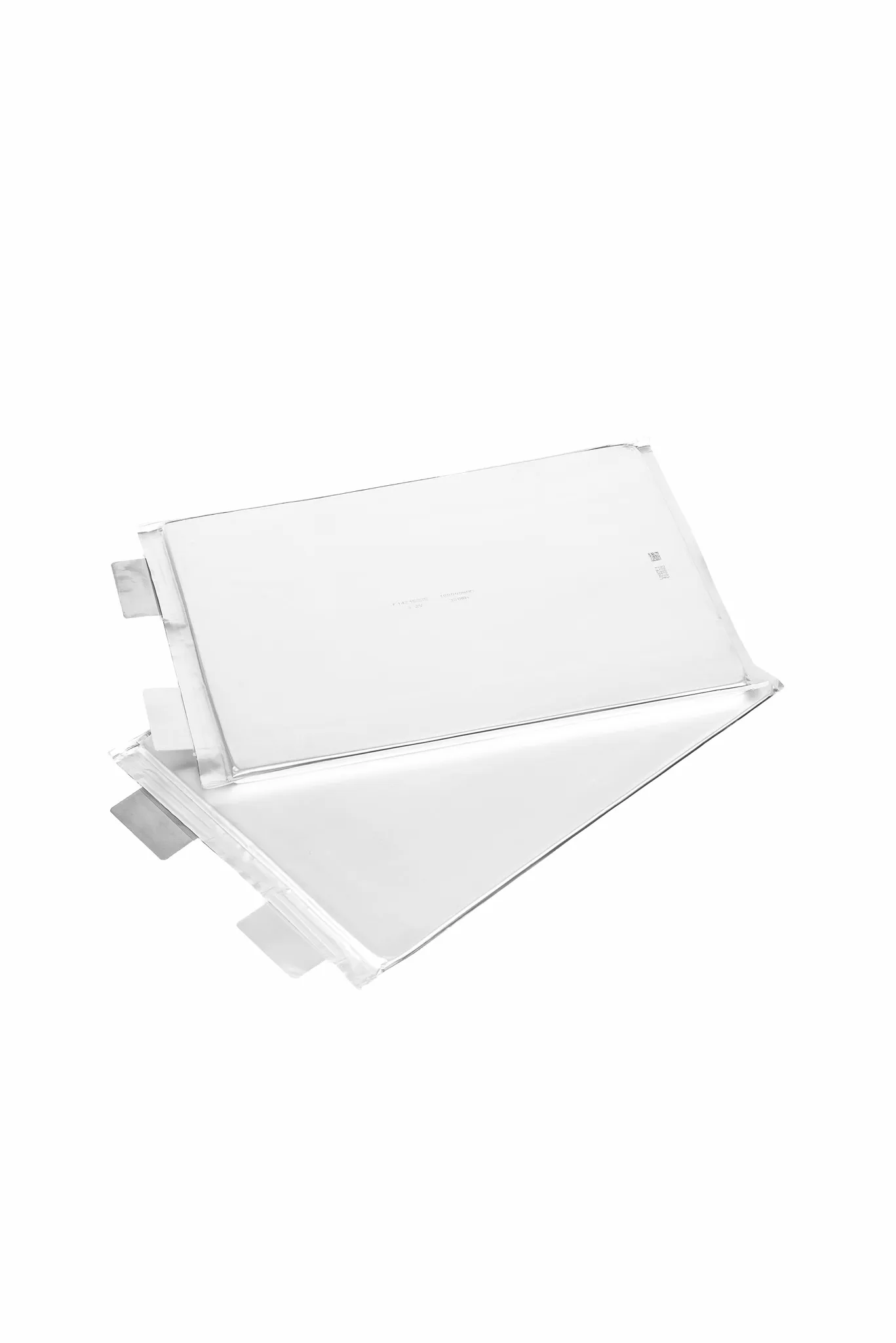

Modelo: 3.2V 31Ah LFP

Descarga continua máxima: 0.5C

Carga continua máxima: 0.5C

Ciclo de vida: ≥4000 veces

Peso de la célula: ~580 g

Modelo: 3.2V 75Ah LFP

Descarga continua máxima: 0.5C

Carga continua máxima: 0.5C

Ciclo de vida: ≥4000 veces

Peso de la célula: ~1400g

Modelo: 3.2V 30Ah LFP

Descarga continua máxima: 0.5C

Carga continua máxima: 0.5C

Ciclo de vida: ≥2000 veces

Peso de la célula: ~585g

Modelo: 3.2V 50Ah LFP

Descarga continua máxima: 0.5C

Carga continua máxima: 0.5C

Ciclo de vida: ≥2000 veces

Peso de la célula: ~935 g

Modelo: 3.7V 45Ah Ternario

Descarga continua máxima: 5C

Carga continua máxima: 1C

Ciclo de vida: ≥800 veces

Peso de la célula: ~550 g

Modelo: 3.7V 33Ah Ternario

Descarga continua máxima: 5C

Carga continua máxima: 1C

Ciclo de vida: ≥800 veces

Peso de la célula: ~395 g

Modelo: 3.7V 35Ah Ternario

Descarga continua máxima: 5C

Carga continua máxima: 1C

Ciclo de vida: ≥800 veces

Peso de la célula: ~405 g

Model: 3.7V 30Ah Ternary

Descarga continua máxima: 5C

Carga continua máxima: 1C

Ciclo de vida: ≥800 veces

Cell Weight: ~400g

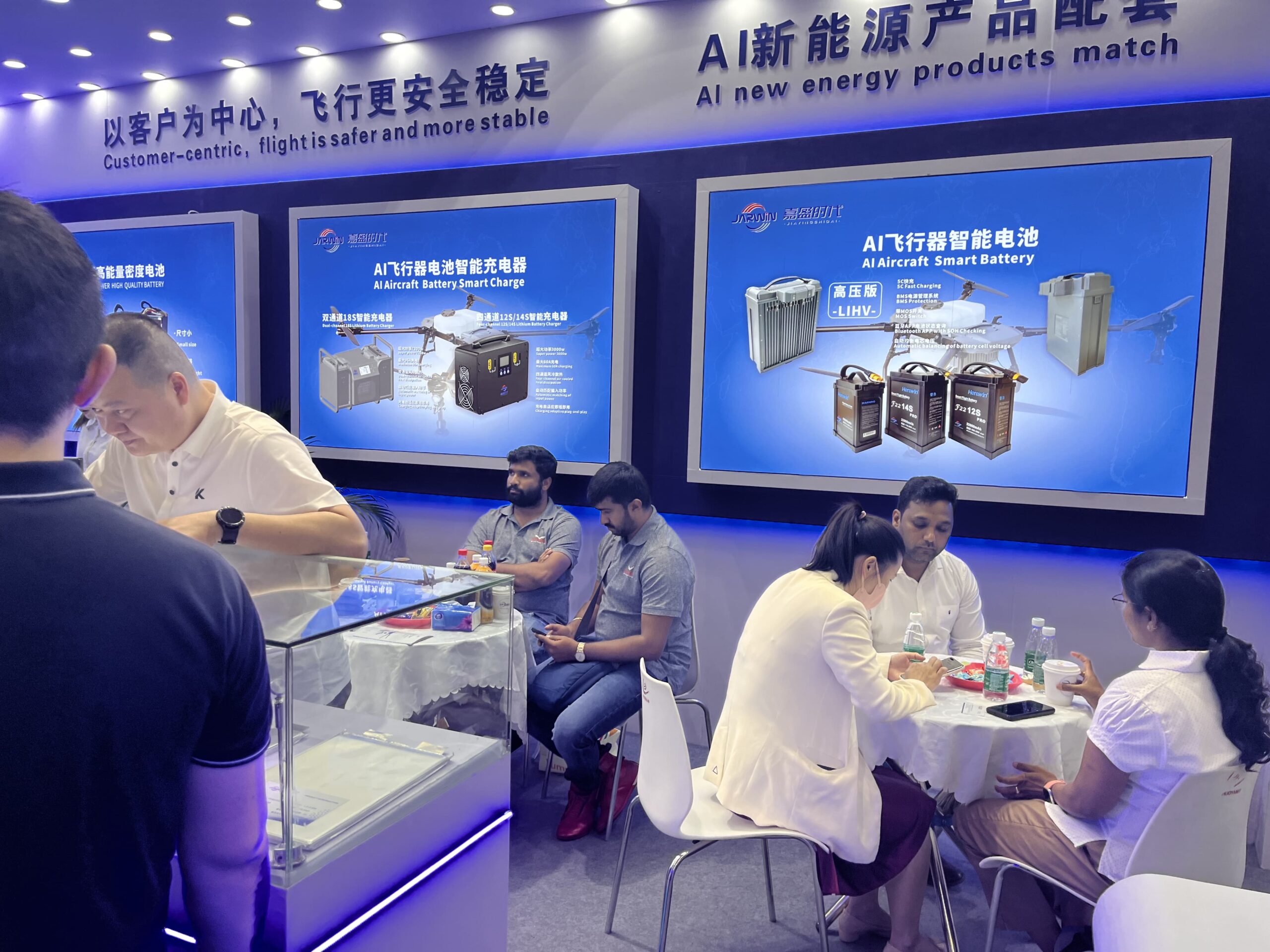

Aplicaciones

Crop spraying operations requiring extended flight time, fast charging, and support for frequent takeoffs/landings in high-intensity environments.

Environmental monitoring, security patrols, or equipment checks; requires weather-resistant operation and persistent endurance.

Stores solar/grid power for household use, prioritizing safety and stable long-term charge/discharge cycles.

Replaces lead-acid batteries for longer runtime and rapid charging in warehouse logistics.

High-density battery cells provide longer range and ultra-fast charging to optimize EV efficiency and quickly replenish power.

DISEÑO GRATUITO

Planes de baterías exclusivos y personalizados Ingenieros profesionales planifican programas de baterías uno a uno.

Maximice el efecto del dron con nuestras soluciones de baterías a medida

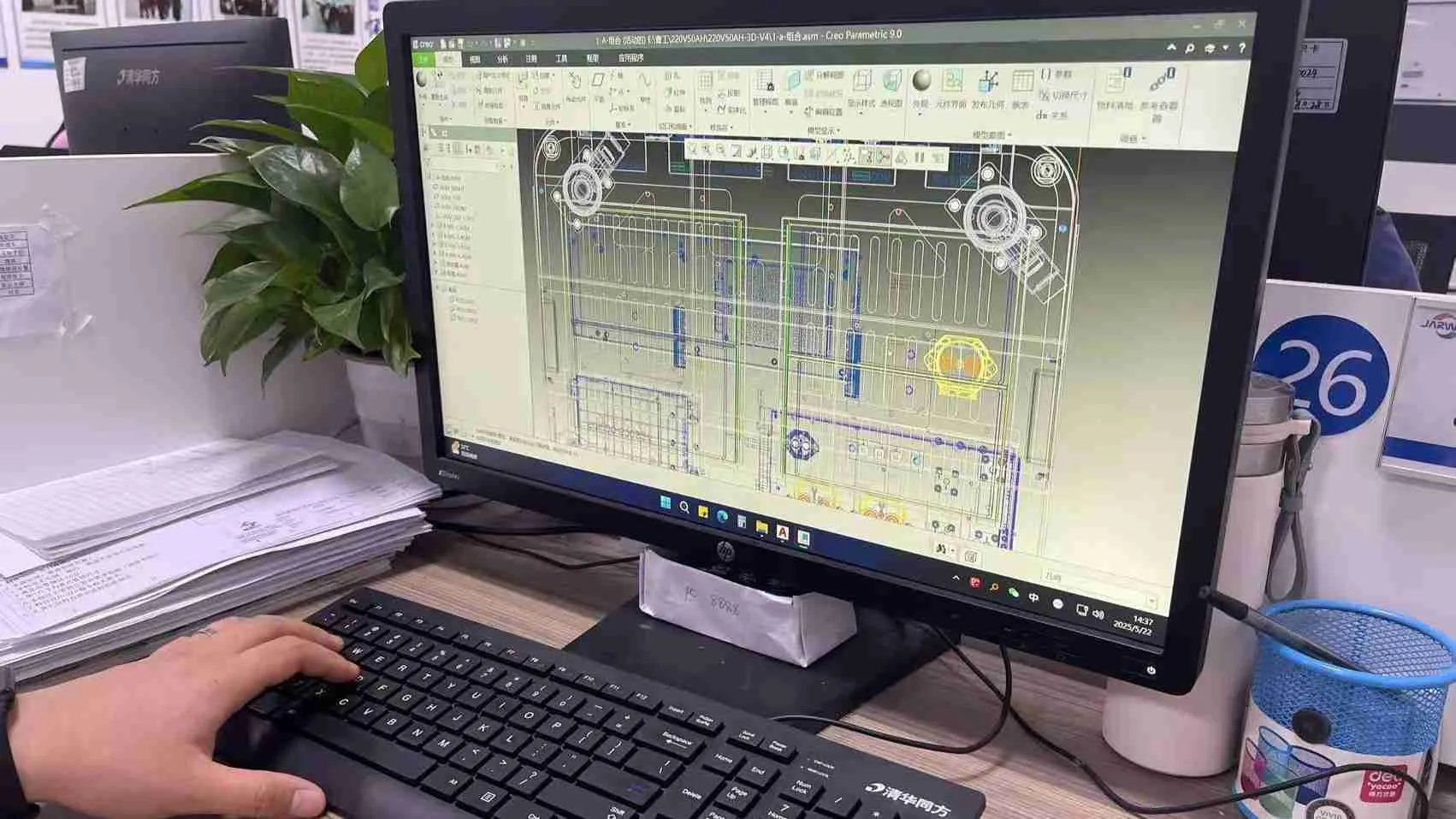

Explore la fábrica Herewin: La fuente de la calidad

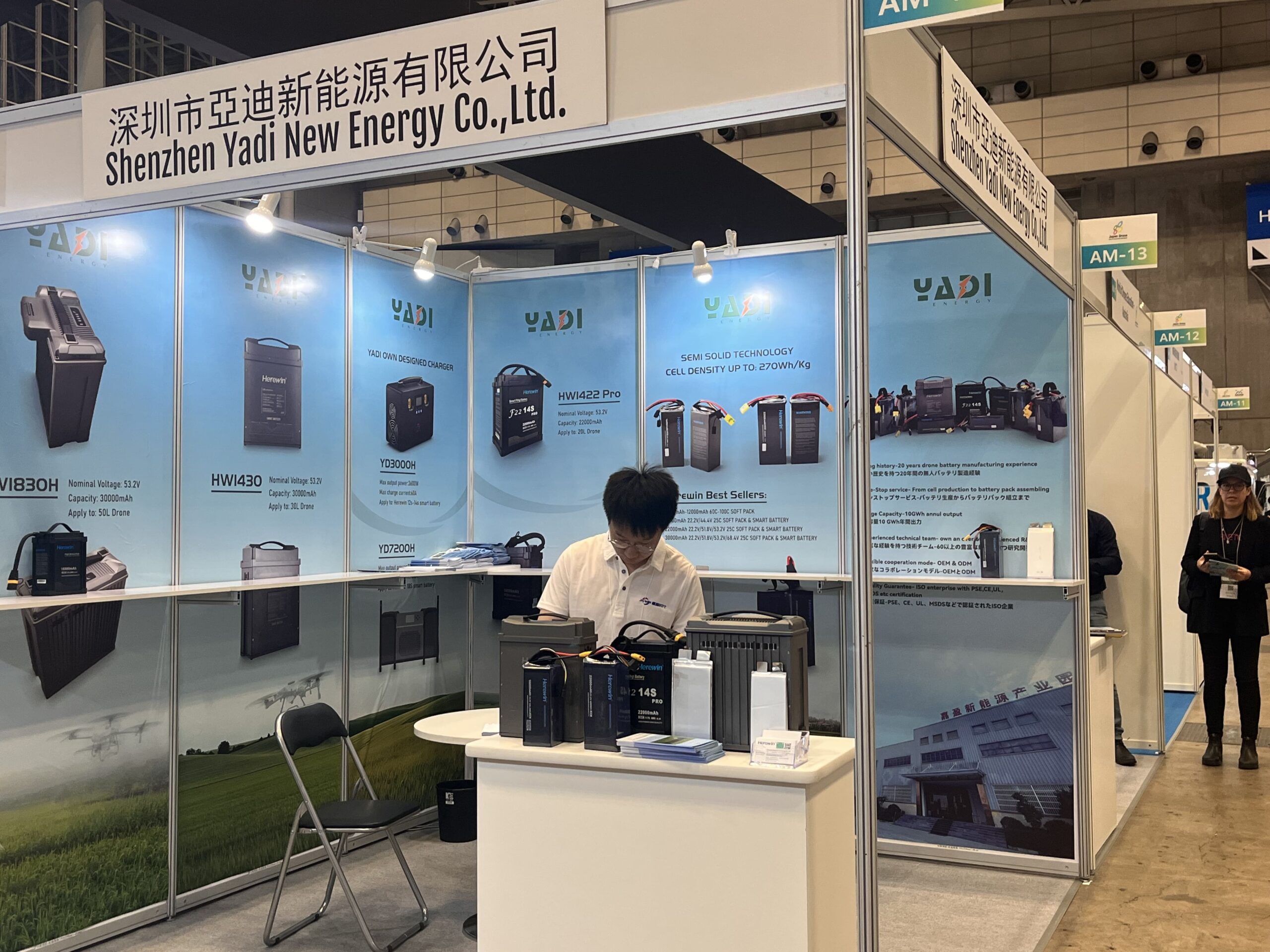

Fundada en 2019, Shenzhen Jarwin Time Technology Co., Ltd. está respaldada por un equipo fundador y operativo con más de 20 años de amplia experiencia en la industria de las baterías. Se especializa en el desarrollo y la producción de baterías de polímero de iones de litio de alto rendimiento.

Descubra quiénes somos y qué representamos. Explorando la meticulosa precisión de nuestros

líneas de producción, la gestión eficaz de nuestras fábricas y la opinión genuina de nuestros clientes satisfechos,

verá cómo garantizamos la excelencia en cada paso del proceso

Distintos servicios para clientes con distintos patrones

PARA CLIENTES OFFLINE

Plazo de entrega flexible

Plazos de entrega fiables y apoyo al almacenamiento.

Alta rentabilidad

Precios competitivos para maximizar el valor global.

Amplia selección de productos

Diversas opciones para todos los segmentos del mercado.

PARA CLIENTES EN LÍNEA

MOQ bajo

MOQ flexible con opciones de productos mixtos.

Logotipo personalizado

Personalización del logotipo para lotes pequeños.

Paquete integral de marketing

Proporcionar imágenes y vídeos de calidad para aumentar los ingresos por ventas.

PARA CLIENTES DE MARCA

Derechos regionales exclusivos

Proporcionar todos los recursos y capacidades de herewin

R&D Resources

Custom sample within 7 days with R&D capabilities.

Entrega rápida

Producción eficiente y envío en 25 días como máximo.

Production Flow of Battery Cells

Blends active materials, binders, and solvents into a uniform slurry to ensure consistent electrochemical performance.

Spreads the slurry onto metal foils (anode/cathode) with precise thickness control for optimal energy density.

Removes solvents from coated electrodes to stabilize material adhesion and prevent cracking.

Combines anode/cathode layers with separators and winds them into a compact jellyroll structure.

Compresses electrodes to enhance density and conductivity while maintaining porosity for ion flow.

Trims electrodes into precise dimensions to fit battery cell specifications.

Aligns anode/separator/cathode layers in a Z-fold pattern to maximize space efficiency.

Joins electrode tabs using laser welding to minimize resistance and ensure current stability.

Seals cells in aluminum-plastic film to protect against moisture, dust, and mechanical stress.

Removes residual moisture from cells under vacuum to prevent electrolyte degradation.

Fills electrolyte into cells to enable ion transport between electrodes.

Activates cells with initial charging to form a stable solid-electrolyte interface (SEI).

Evacuates gas from cells to eliminate air pockets and ensure full electrolyte penetration.

Cycles cells to stabilize performance and screen out defects before final assembly.

Valida la capacidad, la impedancia y la seguridad (por ejemplo, sobrecarga, cortocircuito) según protocolos estrictos.

Integra las células en módulos o paquetes con BMS, cableado y sistemas de gestión térmica.

MÁS DETALLES

Más información sobre los detalles de producción y el proceso de fabricación

Proceso de prueba

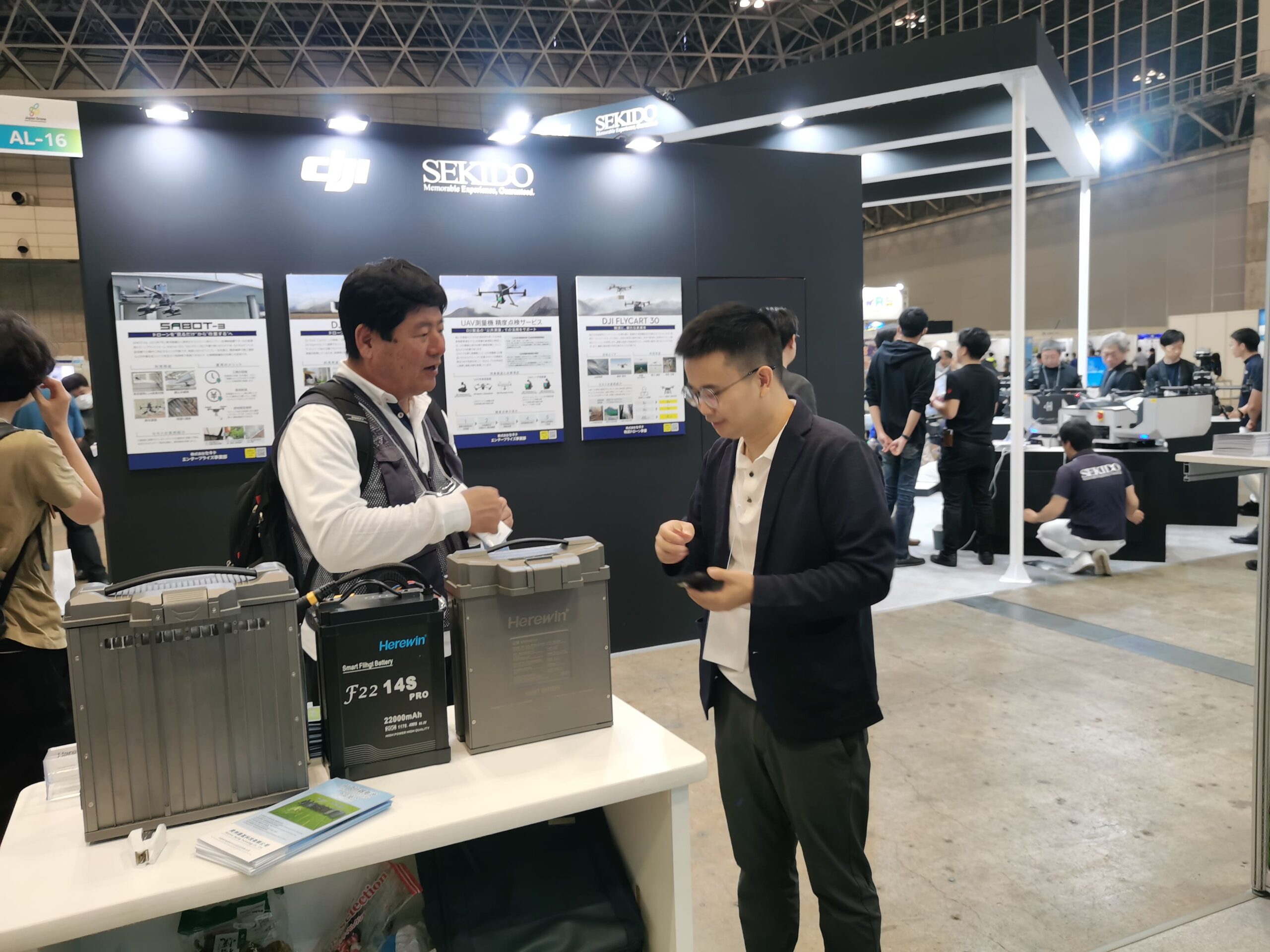

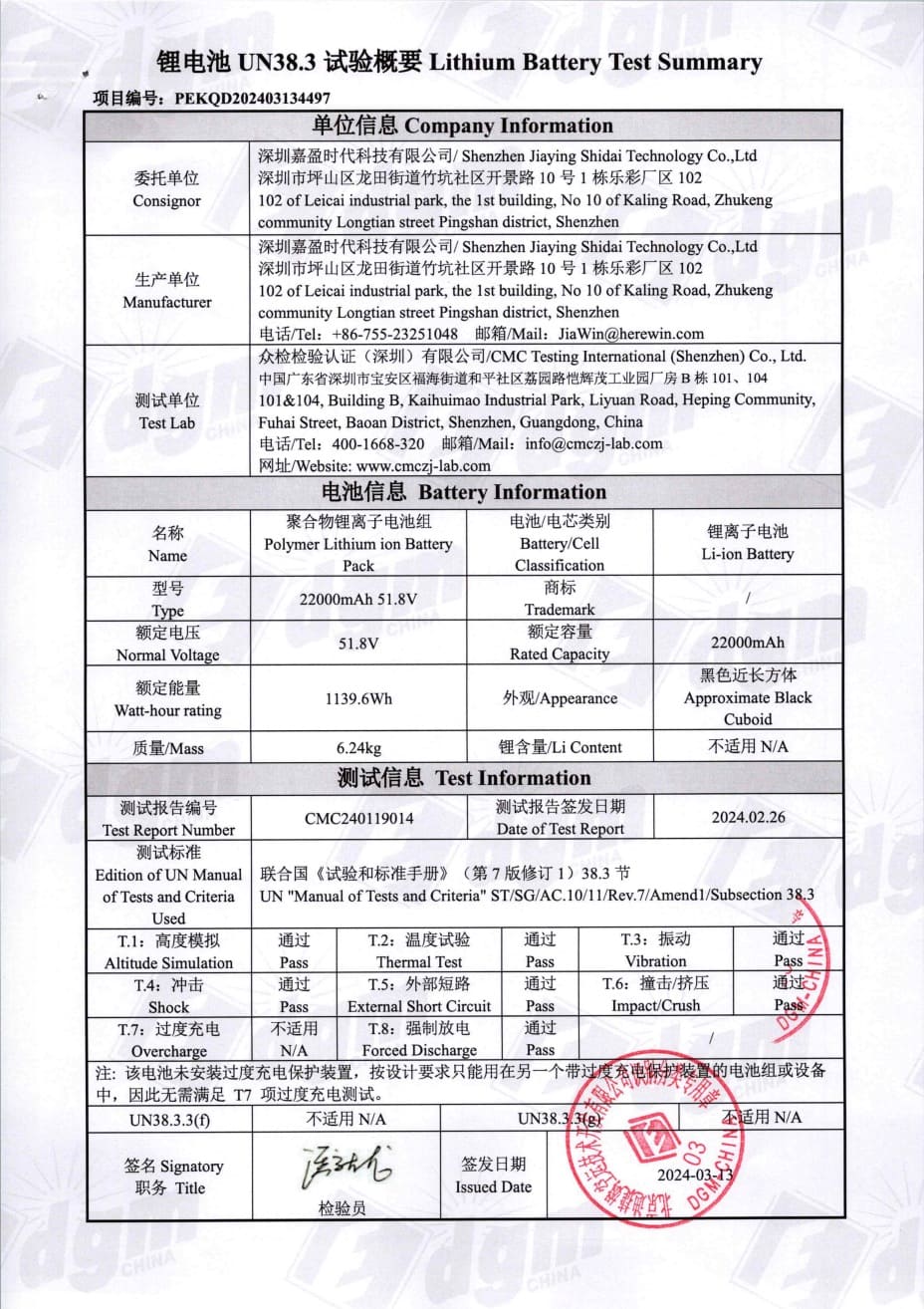

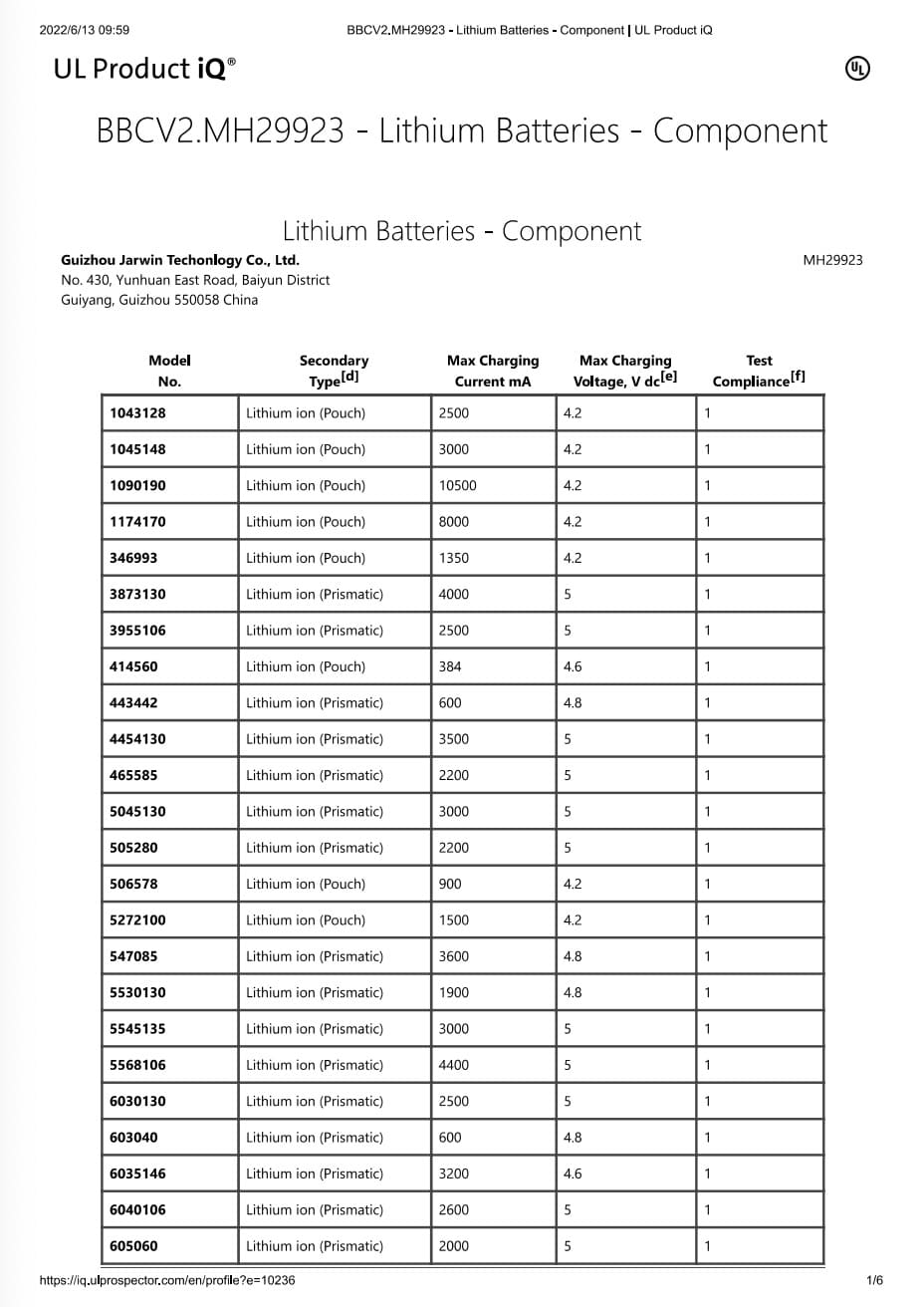

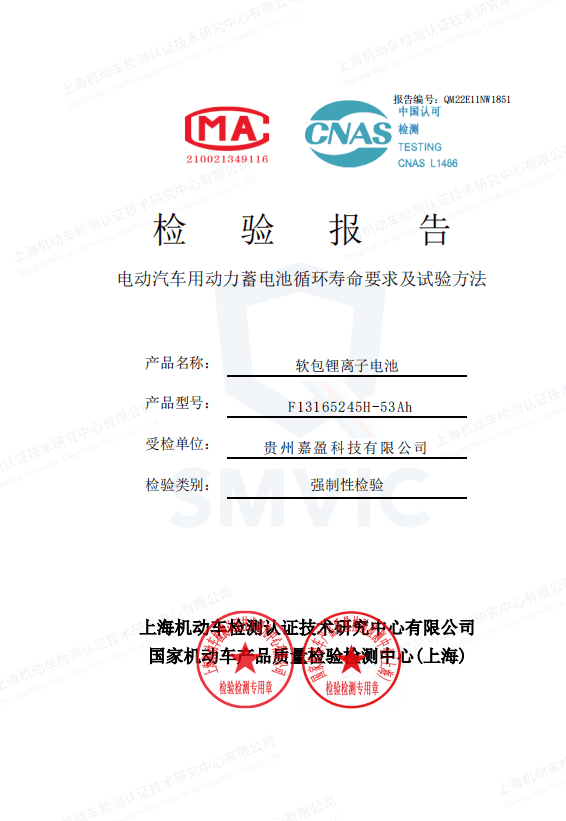

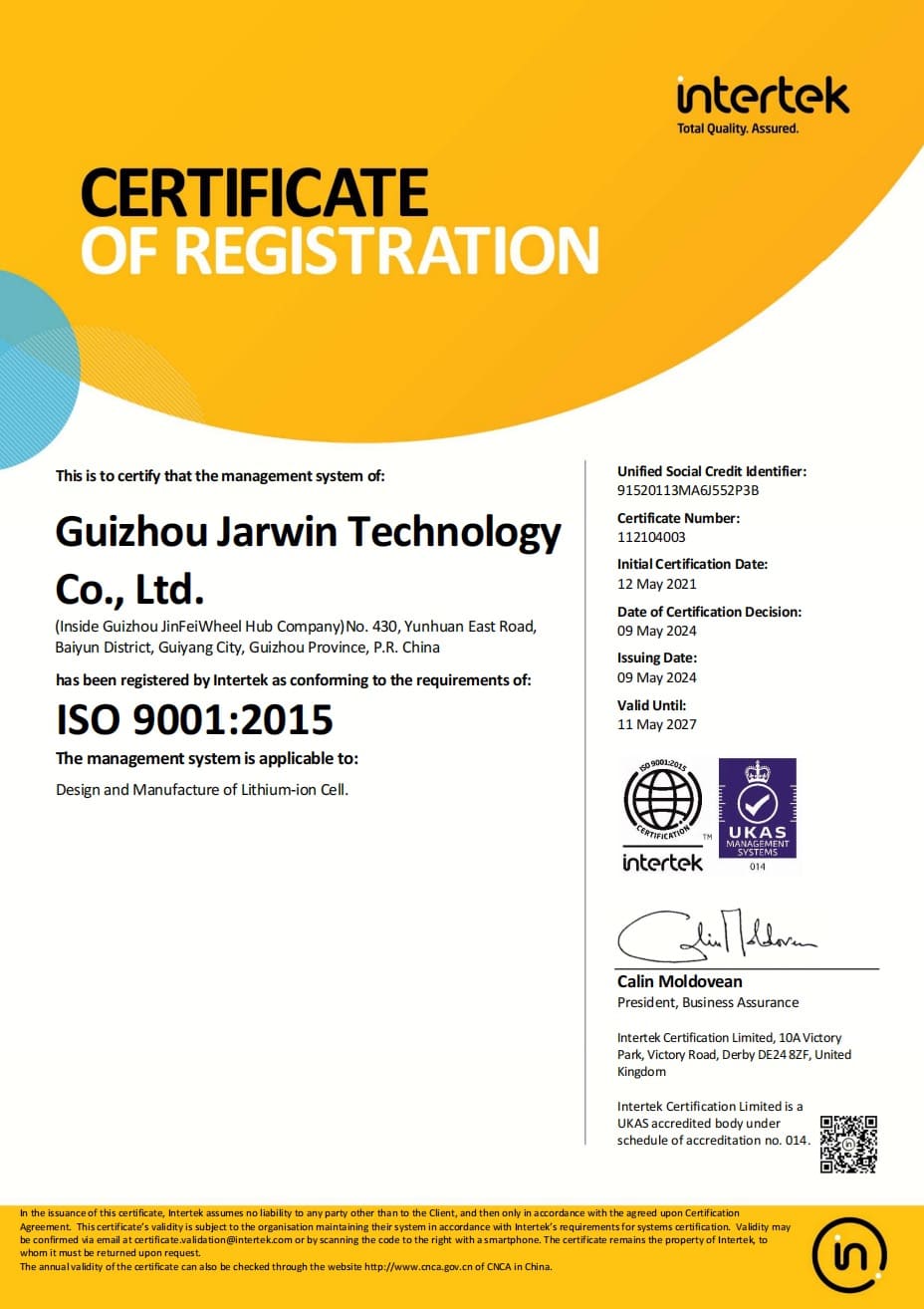

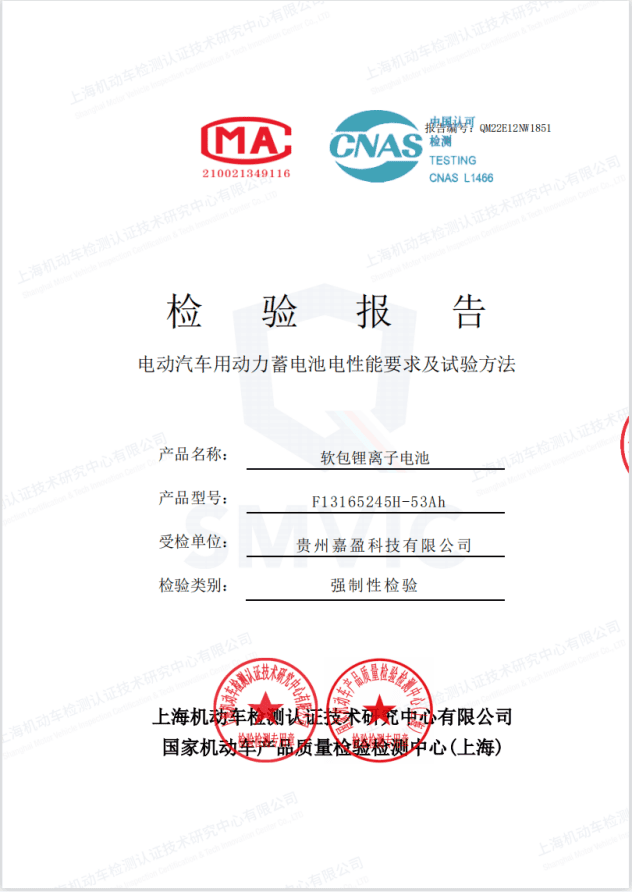

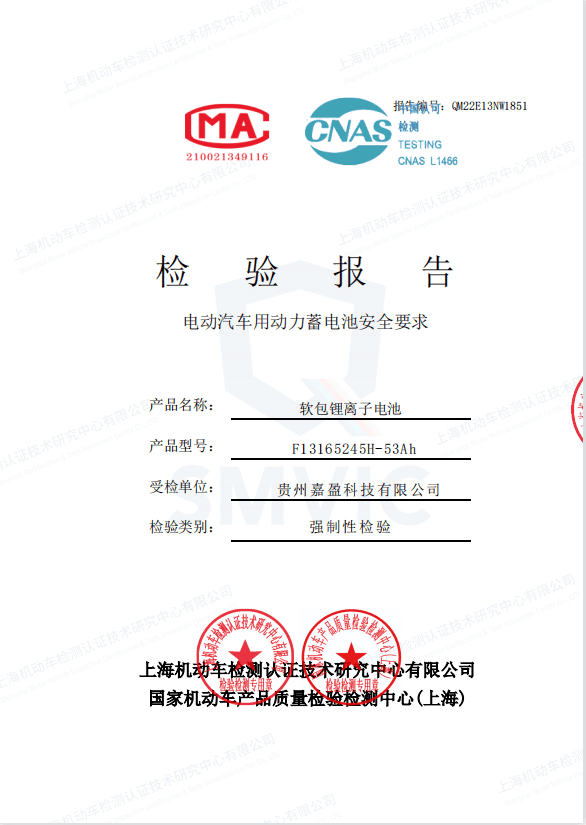

Feria&Certificación

Las certificaciones son el punto fuerte de herewin.

Satisface las necesidades de todos los mercados, y las fábricas de origen están totalmente certificadas para garantizar la calidad.

PONERSE EN CONTACTO

¿Quiere saber qué credenciales necesita su mercado? Póngase en contacto conmigo para enviarle una imagen de alta resolución

Preguntas frecuentes

Li-ion polymer cells utilize gel polymer electrolyte technology, offering key differences compared to traditional liquid lithium batteries:

Electrolyte Composition

-

Hybrid gel polymer + liquid electrolyte (vs. pure liquid electrolyte in traditional cells).

Safety Improvements

-

60% lower leakage risk and 40% reduced combustion potential.

Structural Advantages

-

30% smaller volume, 20% lighter weight, and support for flexible/custom shapes.

Performance Metrics

-

Densidad energética: 170-350 Wh/kg

(Traditional liquid: 160-170 Wh/kg; Semi-solid energy storage series: 170-190 Wh/kg; High-density semi-solid series: 300-350 Wh/kg). -

Charging Efficiency: 50% faster than traditional batteries.

-

Ciclo de vida: ≥2,000 cycles.

-

Safety

-

Passes nail penetration and crush tests.

-

Stable operation at 70-80°C (158-176°F).

-

UL/CE certified.

-

-

Charging Performance

-

30-minute fast charging (up to 80% capacity).

-

Compatible with mainstream fast-charging protocols.

-

-

Sustainability

-

≥2,000-cycle lifespan.

-

95% material recyclability rate.

-

-

Diseño compacto

-

30% smaller size and 20% lighter weight vs. traditional cells.

-

Mainstream Applications

-

Consumer Electronics: Smartphones, TWS earbuds (prioritizing slim designs + fast charging).

-

New Energy Vehicles: Power batteries (20% range increase), flexible in-car displays.

-

Industrial Energy Storage: Residential energy storage systems (safety + longevity), backup power units.

Emerging Applications

-

IoT sensors (flexible integration), vaping devices (miniaturization), wearables.

Blog relacionado

Battery selection is a mission‑critical decision for agricultural drone fleets: the wrong chemistry or inadequate sealing reduces flight duration, limits […]

Industrial mapping teams live and die by endurance, reliability, and data quality. For operators of Platform composite-wing or heavy‑lift multirotors, […]

If you operate a logistics fleet, your battery is more than a component—it affects airtime availability, operational risk, and cross-border […]

Lithium Iron Phosphate (LiFePO4) batteries have become the preferred power source for energy storage, electric vehicles, and portable devices, thanks […]

As the “power core” of drones, lithium batteries directly determine flight stability, endurance, and safety. However, issues like reduced capacity, […]

Nuestro nuevo catálogo

Learn more about battery cell, and the full range of products