As new energy vehicles (NEVs) gain rapid popularity, ternary lithium batteries have emerged as the preferred power source for many electric vehicles (EVs) due to their high energy density and excellent charge/discharge performance. However, battery lifespan and performance degradation remain core concerns for EV owners, and the choice of charging method directly impacts battery health. This article explores the structure and electrochemical mechanisms of ternary lithium batteries, and analyzes the effects of two common charging strategies:

- Charging daily when 50%-55% battery remains, and

- Charging every two days when 20%-25% battery remains.

The goal is to provide EV users with professional recommendations for battery-friendly charging practices.

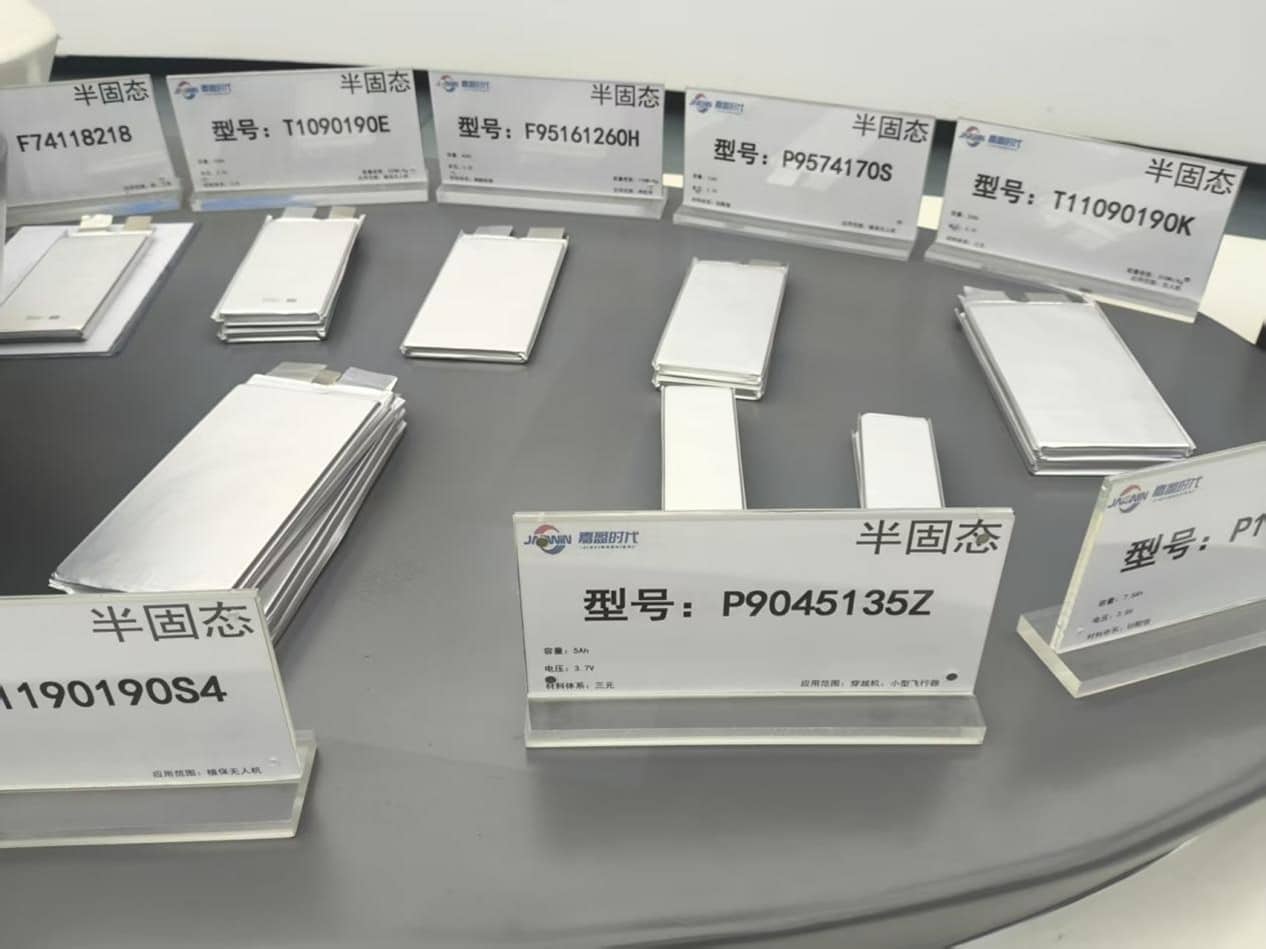

Structure and Working Principle of Ternary Lithium Batteries

Ternary lithium batteries use nickel, cobalt, and manganese (or aluminum) as the key metal elements in the cathode material. The battery’s core components include a cathode, anode, electrolyte, and separator:

- The cathode is usually lithium nickel cobalt manganese oxide (NCM) or lithium nickel cobalt aluminum oxide (NCA).

- The anode is typically made of graphite.

- The electrolyte is an organic solution containing lithium salts.

- The separator is a microporous insulating material that prevents short circuits while allowing lithium-ion transport.

The working mechanism is based on lithium-ion migration: during charging, lithium ions move from the cathode through the electrolyte and embed into the anode’s graphite layers, oxidizing the cathode and reducing the anode. During discharge, lithium ions return to the cathode while electrons flow through an external circuit to power the vehicle. The efficiency of lithium-ion transport and the stability of electrode materials are critical to performance and longevity.

While ternary lithium batteries offer high energy density—thanks largely to the nickel content in the cathode—they are also more sensitive to voltage and current fluctuations during charge/discharge. Nickel improves capacity but has relatively poor chemical stability, making the battery more susceptible to structural degradation under extreme conditions.

Impact Mechanisms of Charging and Discharging

Risks of Deep Discharge

Deep discharging (e.g., when battery drops below 20%) can damage ternary lithium batteries in several ways:

- At low states of charge, the battery voltage drops sharply, causing excessive lithium ion deintercalation from the cathode. This can collapse the crystal structure—especially in NCM cathodes—leading to irreversible phase transitions (e.g., from layered to spinel structure), permanently reducing lithium storage capacity.

- The anode, under low voltage, is prone to electrolyte decomposition. Byproducts such as gases and impurities form passivation films on the electrode surface, increasing internal resistance and impairing ion transport. Polarization becomes severe, requiring higher charging voltage, leading to more heat and energy loss, which accelerates battery aging.

Advantages of Shallow Discharge

Shallow discharge (e.g., charging when 50%-55% remains) avoids these issues:

- The amount of lithium-ion movement is moderate, preserving the crystal integrity of both electrodes.

- Electrochemical reactions proceed more gently with less entropy and enthalpy change, minimizing energy loss and heat generation.

- With reduced polarization and shorter ion transport paths, efficiency improves and thermal stress is lowered.

Effects of the Charging Process

During charging, lithium ions move back to the anode. Fully charging the battery may cause lithium plating, forming lithium dendrites—needle-like structures that can puncture the separator, causing internal short circuits and safety hazards (fire, explosion).

Shallow charging (i.e., not charging to 100%) reduces this risk, as lithium-ion concentration in the anode stays below saturation.

Also:

- High charging voltage accelerates cathode material degradation.

- Excessive charging current causes fast, uneven lithium deposition—promoting dendrite formation.

Best practice: limit the charge cut-off voltage to 80%-90% and avoid high charging currents.

Comparative Analysis of Two Charging Strategies

Cycle Life Comparison

Cycle life refers to the number of charge/discharge cycles a battery can complete before its capacity drops to 80% of the original.

- At 100% depth of discharge (DoD): ~1000–1500 cycles

- At 50% DoD: ~3000–4000 cycles

- At 20% DoD: up to 8000+ cycles

Charging daily at 50%-55% results in shallow discharge (≈45%-50% DoD). With ~300 cycles per year, the battery may last 10–13 years.

Charging every two days at 20%-25% corresponds to deep discharge (≈75%-80% DoD), with a projected life of only 5–7 years.

Capacity Degradation Rate

Battery degradation is also influenced by the charging method:

- Daily 50%-55% charging:

- ~5% degradation after 1 year

- ~15%-20% after 3 years

- Every two days at 20%-25%:

- ~8%-10% after 1 year

- ~30%+ after 3 years

The faster decay is due to structural damage and electrolyte breakdown caused by repeated deep discharges.

Safety Comparison

Shallow cycling is safer:

- Deep discharges increase risks of dendrites and thermal runaway.

- Greater polarization and heat buildup during recharging can trigger thermal instability.

- Shallow cycling reduces these hazards, especially in warm or poorly ventilated conditions.

Energy Efficiency and Cost

Shallow discharges:

- Lower internal resistance = higher charging efficiency = less energy loss.

- For the same driving distance, less electricity is consumed.

- Extended battery life reduces replacement and maintenance costs—improving long-term economic performance.

Practical Recommendations

Optimal Cut-Off Voltage

Set charge limit to 80%-90% rather than full charge. Most EVs allow this setting.

- For daily commuting: 80% is typically sufficient

- For long trips: fully charge to 100% as needed

Temperature Effects

Temperature affects battery chemistry and safety:

- Low temperatures (<0°C):

- Reduced ion mobility

- Avoid deep discharge

- Use slow charging to reduce thermal stress

- High temperatures (>35°C):

- Increases chemical activity and dendrite risks

- Avoid heat exposure and charge in cool, ventilated places

Regular Balancing

Long-term shallow cycling may cause cell imbalance within a battery pack. Perform a balancing charge (100%) every 3–6 months to realign individual cell voltages and restore pack uniformity.

(4) Long-Term Storage

If storing the vehicle for over a month:

- Keep SOC (State of Charge) at 50%-60%

- Avoid both full charge and deep discharge

- Store in a dry, ventilated place at 20°C–25°C

Common Misconceptions

“Deep cycling calibrates battery display”

False. SOC display is handled by the Battery Management System (BMS) and is self-correcting. Deep cycling does not help and instead causes irreversible damage.

(2) “More charging = shorter battery life”

Misleading. It’s not the number of charges but the depth of each cycle that matters.

- One full cycle (100% → 20% → 100%) equals two shallow cycles (100% → 50% → 100%), but causes more stress.

Conclusion

Based on the technical analysis, charging daily when 50%-55% battery remains is clearly superior to charging every two days when only 20%-25% remains. Shallow cycling:

- Protects electrode structure

- Reduces electrolyte decomposition

- Minimizes dendrite formation

- Extends cycle life

- Enhances safety and efficiency

EV users should align their charging behavior with their driving needs and BMS guidelines. By managing temperature, storage, and charging cut-off settings wisely, the service life of a ternary lithium battery can be extended to over 8 years or 150,000 kilometers, maximizing the performance and value of the electric vehicle.